Novel pump sealing gasket for environmental-friendly vehicle

A technology for sealing gaskets and environmentally friendly vehicles, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., and can solve the problems of the quality of sealing gaskets and complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

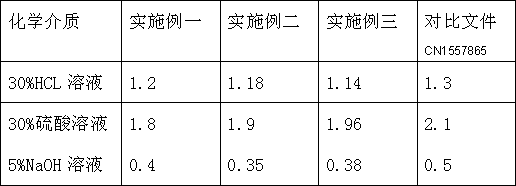

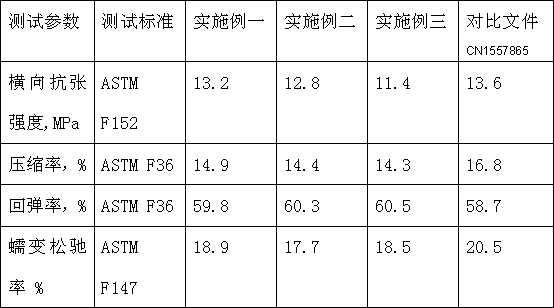

Embodiment 1

[0013] The new environmental-friendly vehicle pump sealing gasket is prepared by mixing raw materials according to the following weight percentages: 9% acrylic pulp, 25% silicate fiber, 14% nylon fiber, 28% silicate filler, neoprene 15%, natural rubber 8%, vulcanizing agent 1%. It is made by one-time sizing and multi-roller continuous calendering and vulcanization.

Embodiment 2

[0015] The new environmental-friendly vehicle pump sealing gasket is prepared by mixing raw materials according to the following weight percentages: 7% acrylic pulp, 35% silicate fiber, 7% nylon fiber, 27% silicate filler, neoprene 12.5%, natural rubber 9%, vulcanization system 2.5%. It is made by one-time sizing and multi-roller continuous calendering and vulcanization.

Embodiment 3

[0017] The new environmental-friendly vehicle pump sealing gasket is prepared by mixing raw materials according to the following weight percentages: 8% acrylic pulp, 30% silicate fiber, 10% nylon fiber, 30% silicate filler, 10% neoprene %, natural rubber 10%, vulcanizing agent 2%. It is made by one-time sizing and multi-roller continuous calendering and vulcanization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com