Functional colored spun yarn, fabric and preparation method thereof

A color spinning and functional technology, applied in the field of fabrics and its preparation, color spinning yarn, can solve the problems of poor washability and antibacterial durability, and high requirements for antibacterial agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 functional color spinning fiber

[0035] 1. Modification treatment and dyeing:

[0036]Modification treatment: the modifier (the weight ratio of nano-silver, chitosan and titanium dioxide is 1:75:18) is prepared into a 20% solution with water, and sodium laurate is added to the solution (modifier and sodium laurate The weight ratio is 1:0.3), stirring vigorously to obtain the modified solution; soak the cotton fiber in the modified solution for 10-15min, and then put the fiber soaked in the modified solution into a sealed reaction kettle, at 120°C Keep the temperature constant for 2 hours under the same conditions, after the reaction is completed, soak in absolute ethanol and water for 10-15 minutes, and dry at 70°C to obtain the modified fiber.

[0037] Dyeing: Put the modified fiber into the dyeing vat and use reactive dyes. The dye formula is: 0.2wt% 3BS red, 0.7wt% 3RS yellow, 1.5wt% Yuanqing B; Pour into the dye vat, keep the temp...

Embodiment 2

[0047] The preparation of embodiment 2 functional colored spinning fibers

[0048] Except for the modifier composition, other preparation methods are the same as in Example 1. In this embodiment, the modifier consists of nano-silver, chitosan and titanium dioxide in a weight ratio of 1:70:22.

Embodiment 3

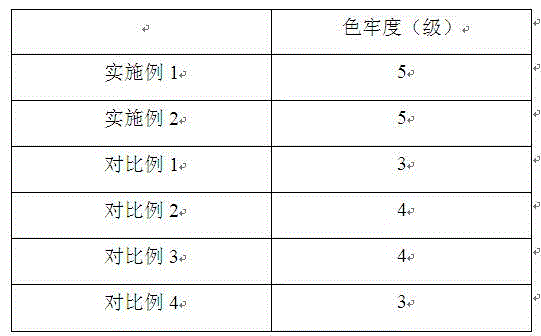

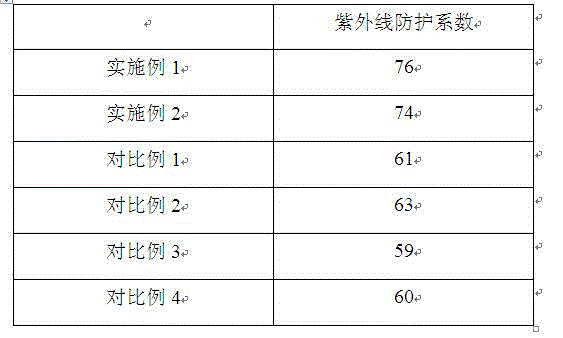

[0049] Embodiment 3 color fastness test

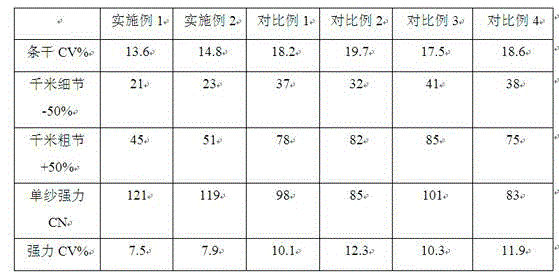

[0050] The functional color spinning fiber prepared by using Examples 1 and 2 is processed into textiles, and according to the national standard GB / T 3920-2008 "Textile Color Fastness Test Color Fastness to Rubbing", the cotton is measured with the YG571 type color fastness tester. The color fastness to rubbing of fibers, in addition, in order to illustrate the effect of the present invention, the following comparative examples are specially set, and the comparative examples are except that the modifying agent is formed, and other preparation methods are all the same as embodiment 1, and the comparative example modifying agent is composed as follows:

[0051]

[0052] The specific results are as follows:

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com