Heat pump drying system

A technology of heat pump drying and heat pump, which is applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems of large floor area, and achieve the effects of reducing operating costs, improving quality, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

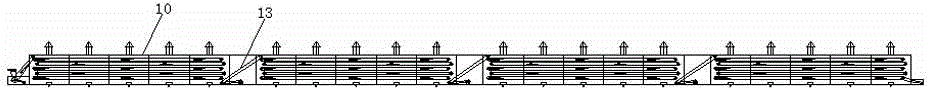

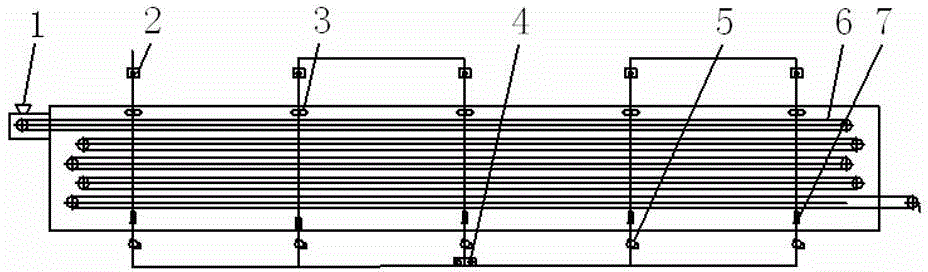

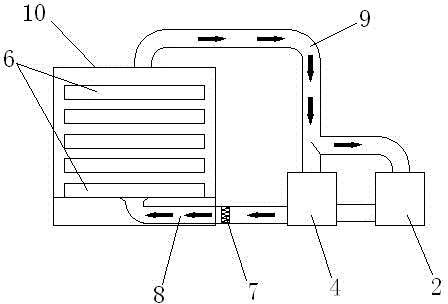

[0022] A heat pump drying system, comprising a plurality of drying chambers 10 connected in series, each drying chamber is provided with a transmission mesh belt 6 for conveying materials, the transmission mesh belt 6 is provided with mesh holes capable of ventilation, and the mesh The hole size should not be smaller than the material. The discharge end of the transmission mesh belt in the previous drying chamber is connected to the feed end of the transmission mesh belt in the next drying chamber by the feeding device 13 . Each drying chamber 10 is provided with an independently controlled hot air supply mechanism. The air outlet of the hot air supply mechanism is located below the drying chamber 10, and an exhaust mechanism for discharging humid air is also provided above the drying chamber.

[0023] The hot air supply mechanism is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com