Grinding device for biological tissue

A biological tissue and grinding device technology, applied in the preparation of test samples, etc., can solve the problems of single sample size, long grinding time, easy slipping, etc., to meet the experimental requirements, reduce the cost of the test, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

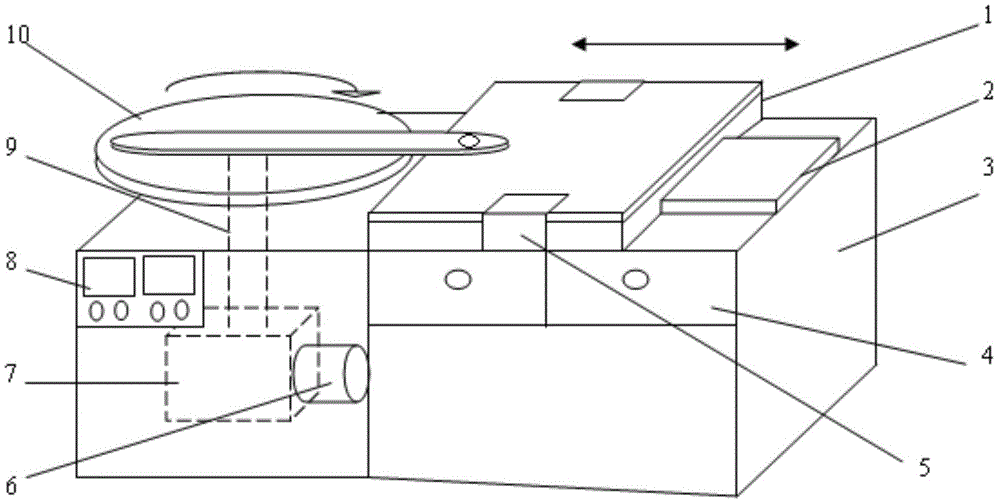

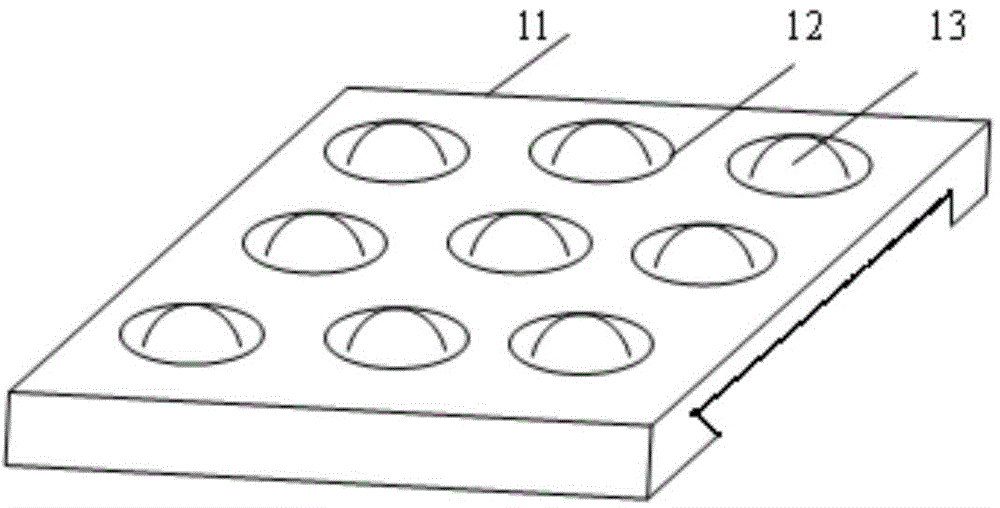

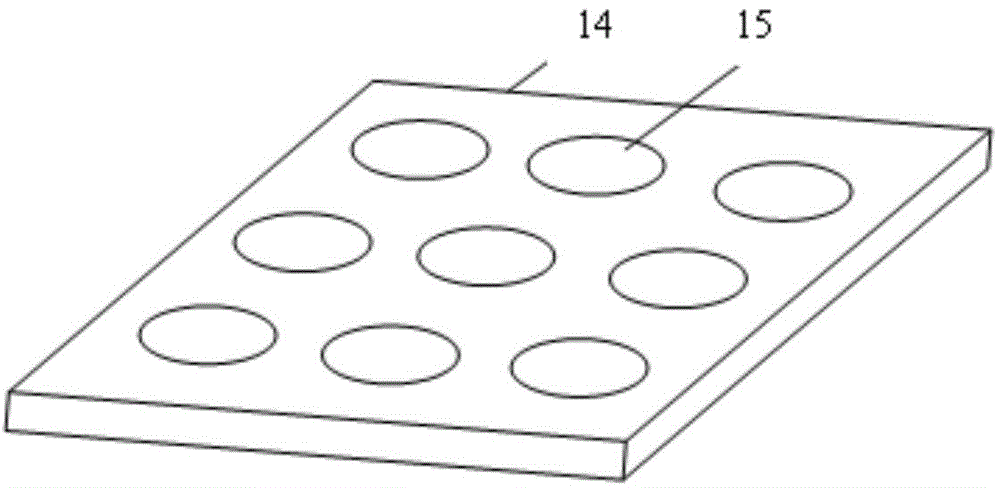

[0014] refer to figure 1 . A grinding device for biological tissue, comprising a grinding table 3, an electric device (a motor 6 and a gearbox 7) is provided in its left half, a control panel 8 is installed in the front, and the grinding work is controlled by an electronic control circuit time and speed. The gearbox 7 is connected to the wheel disc 10 through a vertical transmission shaft 9, and a crank connecting rod is provided on the wheel disc to connect a grinder 1 located on the right half of the grinding table, and the grinder is provided with a dovetail groove ( figure 2 ) is matched with the guide rail 2 on the grinding table. Driven by the drive shaft, the wheel disc 10 converts the circular motion into the linear motion of the end of the connecting rod through the crank connecting rod mechanism, and drives the grinder to reciprocate left and right along the guide rail. There is a drawer 4 in the grinding table below the grinder, in which an ice box is arranged to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com