Multifunctional vacuum preloading consolidation experiment apparatus and method for performing closed type vacuum preloading experiment

An experimental device and multi-functional technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve the effect of simplifying the loading and unloading process and facilitating experimental operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

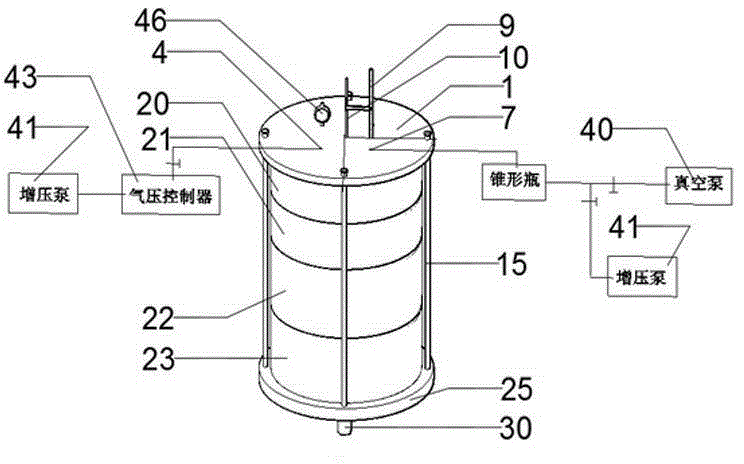

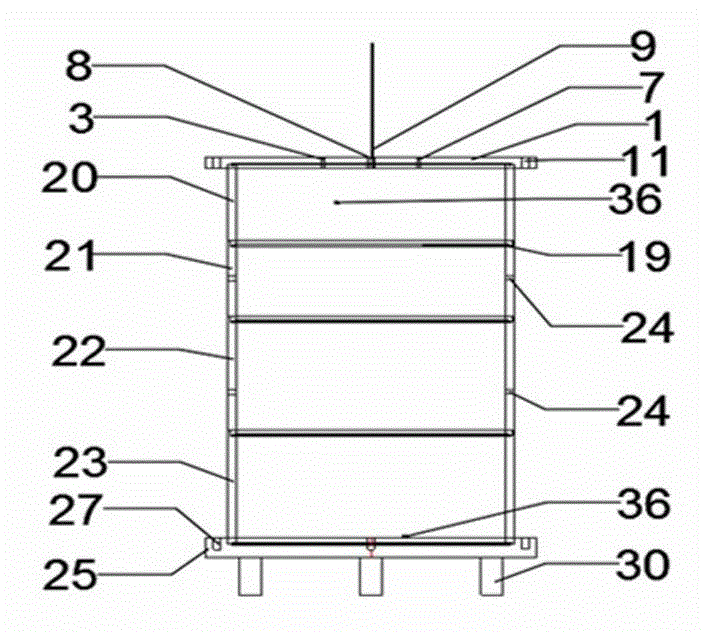

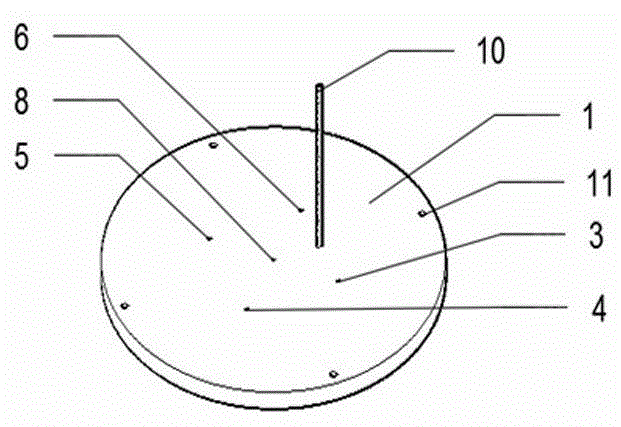

[0054] see figure 1 , figure 2 , the multifunctional vacuum preloading consolidation experimental device provided by the present invention includes a vacuum preloading consolidation chamber, which is composed of a top plate 1, a base 25, and a rigid transparent sleeve. The rigid transparent sleeve includes an upper sleeve 20, an upper middle sleeve 21, a lower middle sleeve 22, and a lower sleeve 23. The upper surface of the upper sleeve 20 is embedded in the top plate sleeve groove 2 provided on the top plate 1, and the lower sleeve The lower surface of 23 is embedded in the base sleeve groove 26 provided on the base 25, and the upper sleeve 20, the upper middle sleeve 21, the lower sleeve 22 and the lower sleeve 23 are formed by the lower surface of the upper sleeve. The sleeve connection protrusion 17 is engaged with the sleeve connection groove 16 on the upper surface of the lower sleeve; The pressure-tight high-strength pre-compression film 14 provided by the axial cl...

Embodiment 2

[0070] This implementation example is used to simulate the pressurized vacuum preloading test research, which is basically the same as the first implementation example, the difference is:

[0071] In step 2 of Example 1, before laying the high-strength pre-compressed membrane, a pressurized filter pipe (see utility model patent ZL03220509.0) is installed. The pressurized filter pipe is composed of a spiral elastic support frame and a filter The front end of the booster filter tube is screwed with a tapered head, and the rear end of the last booster filter tube is screwed with a flange. One end of the thin hose is connected to the flange, and passes through the air pressure measurement hole 4 to connect with the air pressure control. One side of the air pressure controller 43 is connected with the booster pump 41, and the air pressure required for the experiment can be controlled by the air pressure controller. At this time, the valve connecting the air pressure controller to t...

Embodiment 3

[0073] This implementation example is used to simulate positive and negative pressure cycle preloading test research, which is basically the same as the first implementation example, the difference is:

[0074] In the 6th step in the implementation example one, block the air vent hole 5 with the sealing bolt 6, keep the air vent hole 5 sealed, close the branch pipeline valve connected to the three-way interface and the booster pump 41, open the three-way interface and the taper Open the valve of the branch pipeline connected to the bottle 39, open the valve of the branch pipeline connected with the vacuum pump 40, and turn on the vacuum pump 40 to carry out the pre-consolidation test of vacuum preloading. After the degree of consolidation of the soil reaches 40%, close the branch pipeline valve connected with the vacuum pump 40, and close the vacuum pump 40, open the branch pipeline valve connected with the booster pump at the same time, open the booster pump 41, and control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com