Lead frame and its chip package

A technology of chip packaging and lead frame, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., to achieve the effects of saving PCB space, facilitating high circuit integration, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

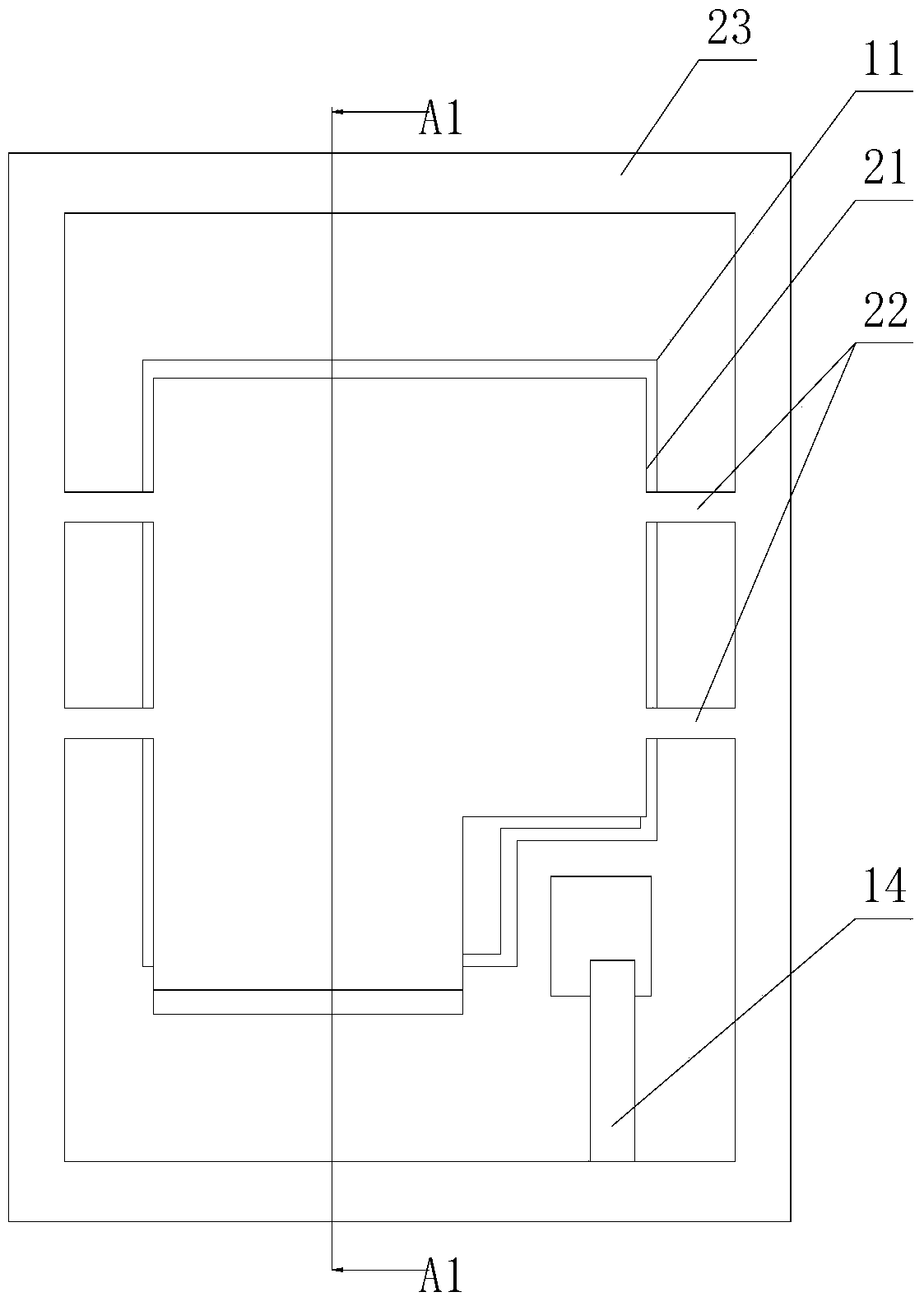

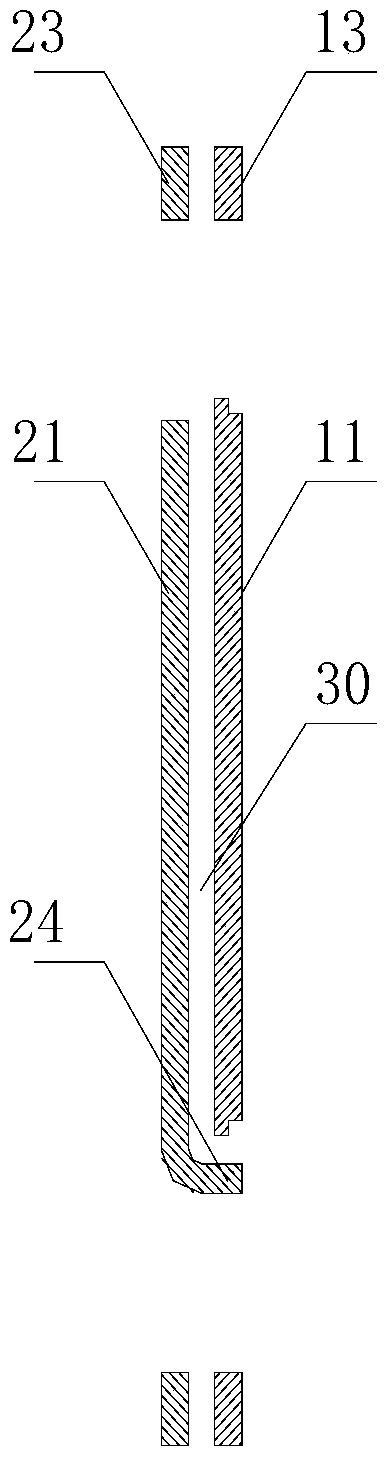

[0043] refer to Figure 1 to Figure 6 , the lead frame provided in Embodiment 1 of the present invention includes a first lead frame and a bridge frame,

[0044] The first lead frame includes a first chip holder 11, a plurality of first connecting rods 12, a first outer pin 14 and a first outer frame 13, the outer end of the first connecting rod 12 is connected to the first Outer frame 13 is connected, and its inner end is connected with described first chip seat 11, and the outer end of described first external pin 14 is connected with described first outer frame 13, and its inner end is placed on described first chip. The gate of the chip on seat 11 is turned on,

[0045] The bridge frame includes a second chip holder 21, a plurality of second connecting rods 22 and a second outer frame 23, the outer ends of the second connecting rods 22 are connected to the second outer frame 23, and the inner ends thereof are connected to the second outer frame 23. The second chip holder...

Embodiment 2

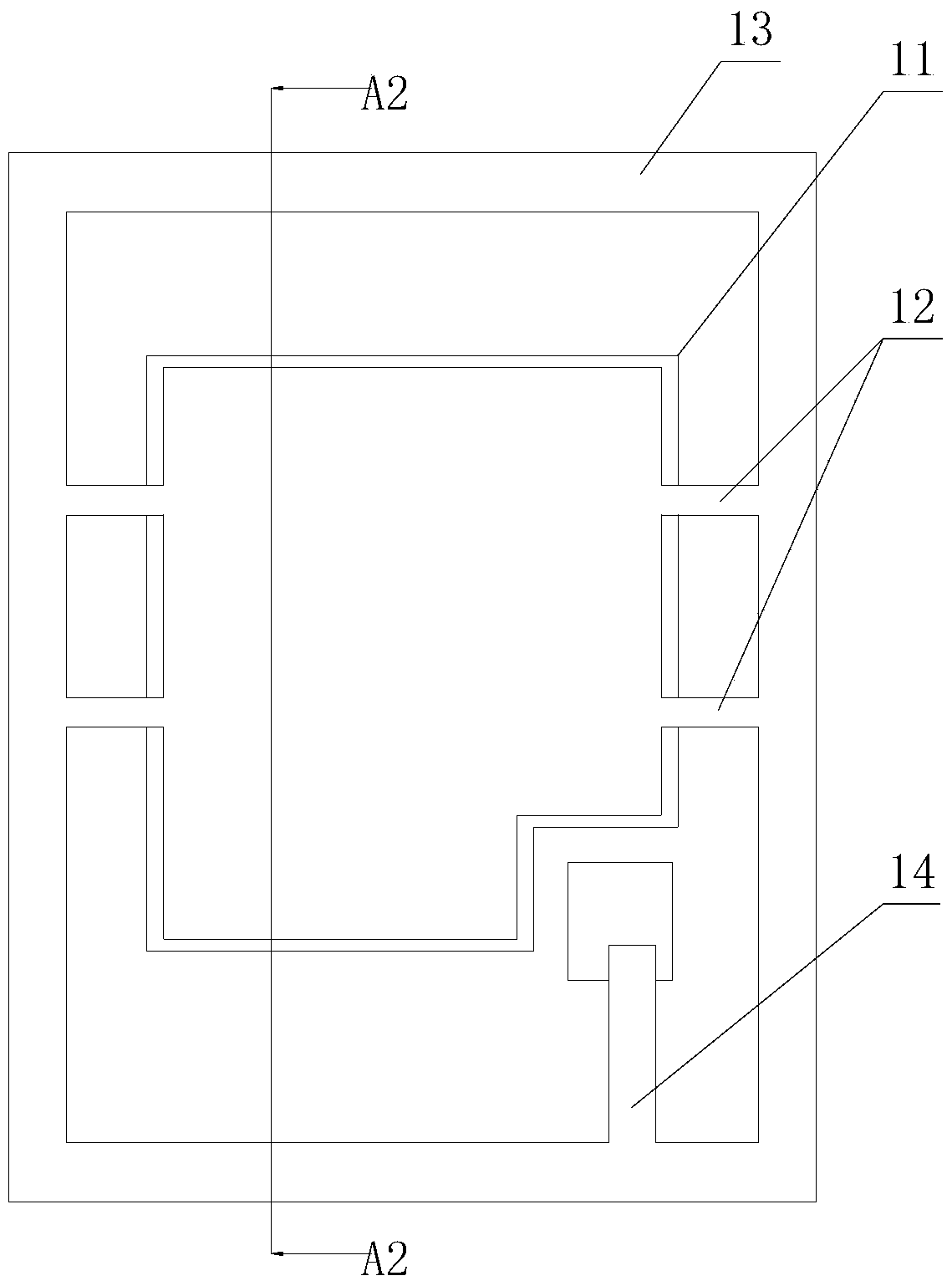

[0051] refer to Figure 7 to Figure 10 , the chip package provided by Embodiment 2 of the present invention includes:

[0052] The first lead frame, the first lead frame includes a first chip holder 11, a first external pin 14 and a plurality of first connecting rods 12, the inner ends of the first connecting rods 12 are connected to the first chip holder 11 connection, the inner end of the first external pin 14 is conducted with the gate of the flip chip placed on the first chip holder 11;

[0053] A bridge frame, the bridge frame is superimposed on the first lead frame, the bridge frame includes a second chip holder 21, a plurality of second connecting rods 22, the inner ends of the second connecting rods 22 are connected to the The second chip holder 21 is connected, the bottom of the second chip holder 21 is provided with a folded edge 24, the bottom of the folded edge 24 is on the same level as the lower surface of the first chip holder 11, and the first chip A space 30...

Embodiment 3

[0060] refer to Figure 11 to Figure 14 The main difference between the chip package provided by Embodiment 3 of the present invention and the chip package provided by Embodiment 2 is that the upper surface of the bridge frame leaks outside the encapsulant 50 . Other structures are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com