A driving method of a tilting sub-tower piezoelectric motor with anti-friction and modal drive

A driving method, piezoelectric motor technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve problems such as limiting the scope of application of piezoelectric motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Aiming at the deficiencies of the prior art, the present invention proposes an anti-friction and modal drive, which can realize forward and reverse motion, has a simple structure, a large thrust-to-weight ratio, high excitation efficiency, high vibration energy utilization rate, and fast response speed. Sub-tower piezoelectric motor and its driving method.

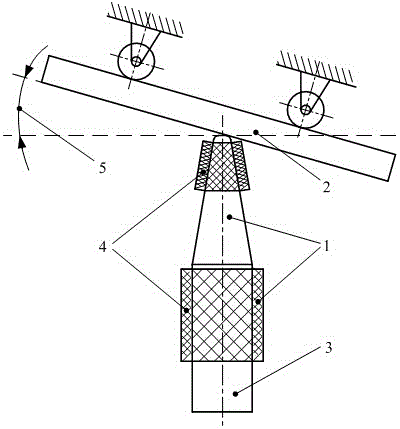

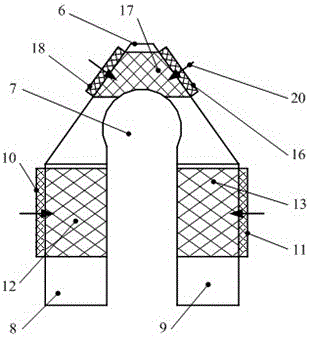

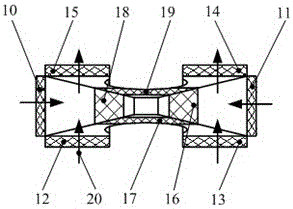

[0065] The structure of a tilting sub-tower piezoelectric motor with anti-friction and modal drive is as follows: figure 1 As shown, the oblique mover tower motor is composed of a tower stator 1 and an inclined mover 2, wherein the inclined mover 2 is a linear guide rail with an inclined installation angle 5 of θ degrees, and the linear guide rail 2 is under the action of preload Press on the driving foot 6 of the tower-shaped stator 1; the tower-shaped stator 1 is composed of a tower-shaped metal body 3 and a total of ten pieces of piezoelectric ceramics 4 in three phases, wherein the tower-shaped metal body 3 cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com