Welding tool and method of medium carbon steel hollow step bar

A technology of welding tooling and ladder rods, applied in welding equipment, welding equipment, laser welding equipment, etc., can solve problems such as easy to generate defects, difficult to complete welding tasks, welding technical requirements, poor weldability, etc., to achieve controllable welding process, Fast and convenient assembly and disassembly, good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

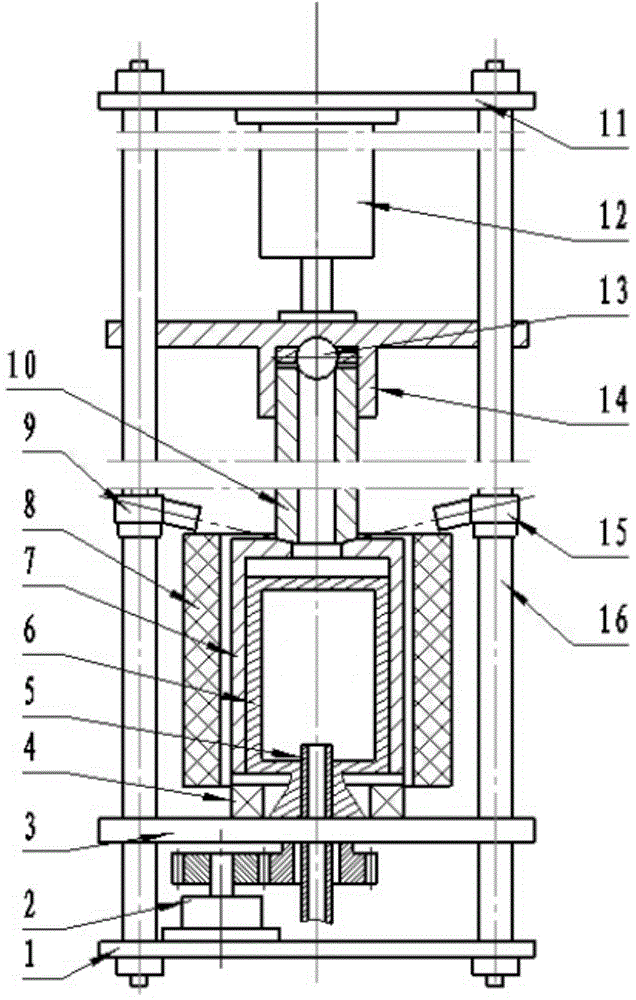

[0028] Such as figure 1 A welding tool for a medium-carbon steel hollow ladder bar is shown, which has a load-bearing frame, and a clamping mechanism is arranged in the load-bearing frame. The preheating welding system is installed on the load-bearing frame and cooperates with the clamping mechanism; the load-bearing frame includes Column 16, column 16 is provided with upper support plate 11, middle support plate 3 and lower support plate 1 successively from top to bottom; And the positioning sleeve 14 that is detachably connected with the clamping cylinder 12, the inner diameter of the positioning sleeve 14 matches the outer diameter of the thin hollow rod 10 in the medium carbon steel hollow ladder rod, the positioning sleeve 14 and the thin hollow rod 10 are clearance fit, and the positioning The inside of the sleeve 14 is provided with a steel ball 13 for auxiliary rotation, and a hollow positioning piece 6 coaxial with the positioning sleeve 14 is provided below the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com