Preparation method for simethicone

A technology of simethicone and simethicone, which is applied in the field of preparation of simethicone, can solve the problems of large power consumption, etc., and achieve the effects of saving production time, good defoaming effect, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

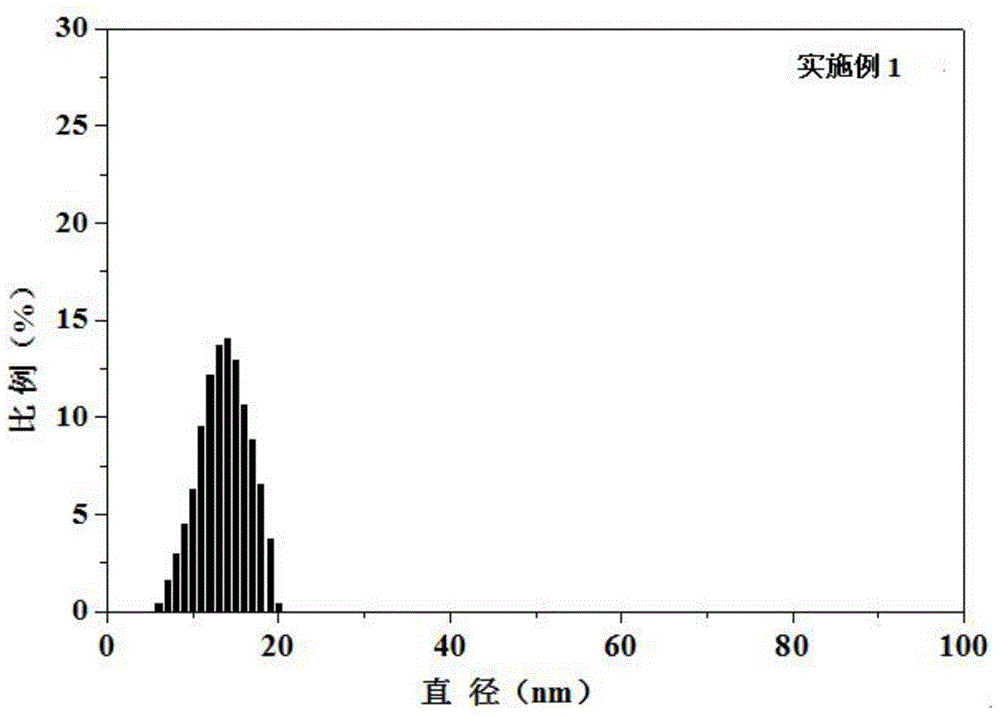

Embodiment 1

[0025] A preparation method for Simethicone, comprising the following steps:

[0026] Step (1): Take 945g of simethicone, add 55g of silicon dioxide, keep warm at 55°C, stir to disperse evenly, and set aside.

[0027] Step (2): Get above-mentioned mixed solution, place in the hopper of Rannie 5 / Gaulin 5 type high-pressure homogenizer (Germany APV company), pressure is 55MPa, and pressure holding time is 60 minutes; Emit feed liquid, obtain final product.

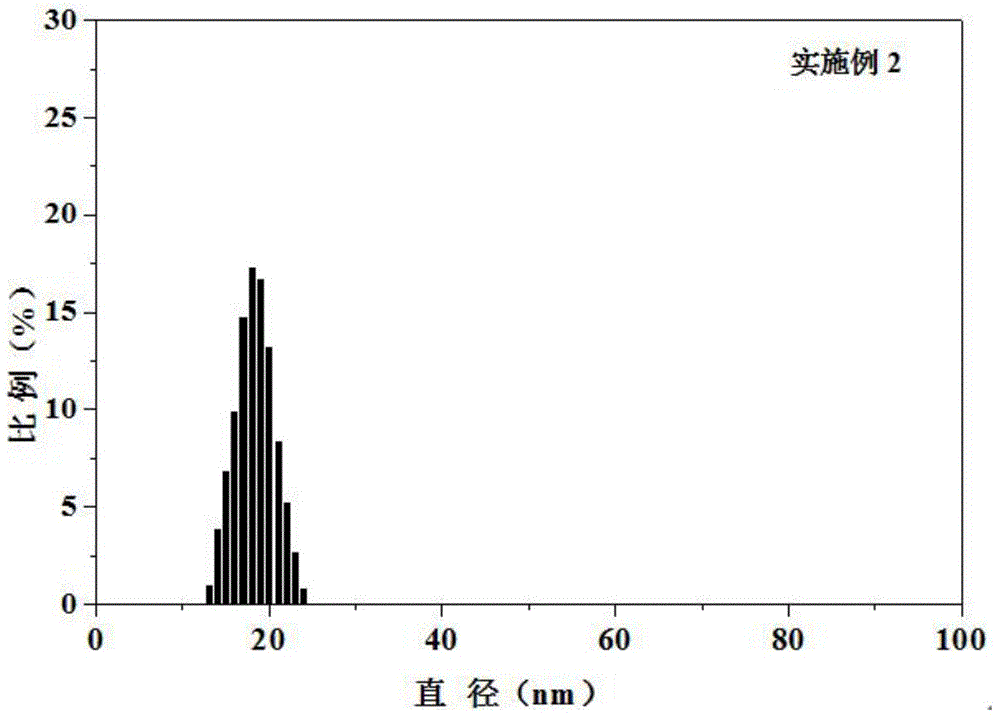

Embodiment 2

[0029] A preparation method for Simethicone, comprising the following steps:

[0030] Step (1): Take 945g of simethicone, add 55g of silicon dioxide, keep warm at 65°C, stir to disperse evenly, and set aside.

[0031] Step (2): Get above-mentioned mixed solution, place in the hopper of Rannie 5 / Gaulin 5 type high-pressure homogenizer (Germany APV company), pressure is 95MPa, and pressure holding time is 30 minutes; Emit feed liquid, obtain final product.

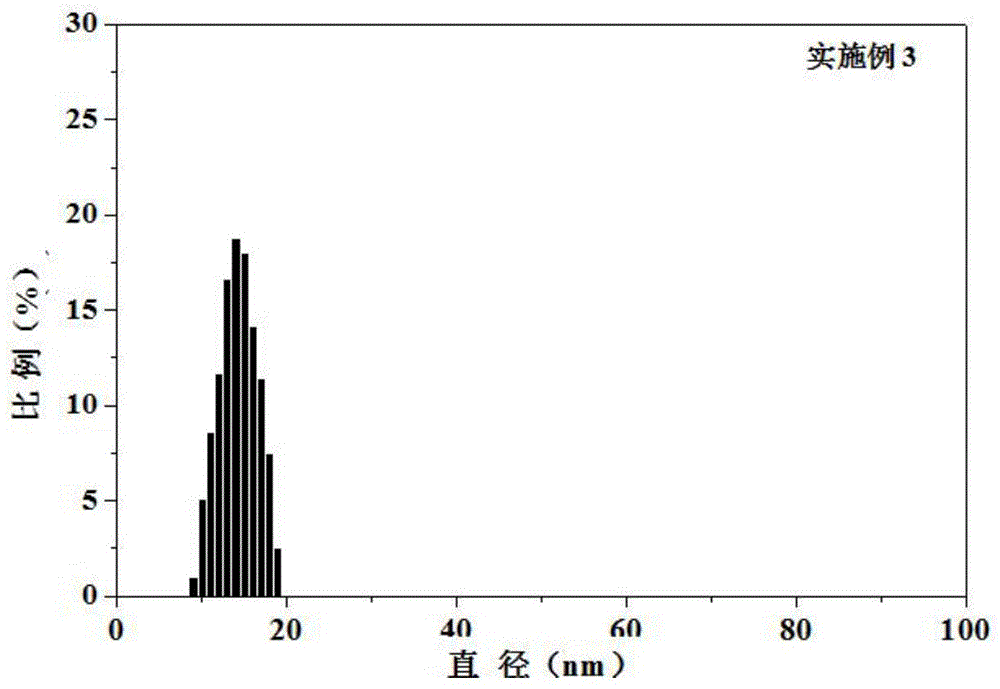

Embodiment 3

[0033] A preparation method for Simethicone, comprising the following steps:

[0034] Step (1): Take 945g of simethicone, add 55g of silicon dioxide, keep warm at 75°C, stir to disperse evenly, and set aside.

[0035] Step (2): Get above-mentioned mixed solution, place in the hopper of Rannie 5 / Gaulin 5 type high-pressure homogenizer (Germany APV company), pressure is 85MPa, and holding time is 40 minutes; Emit feed liquid, obtain final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com