Hollow composite floor slab and construction method thereof

A technology of superimposing floor slabs and hollow cores, applied in the direction of slabs, building components, buildings, etc., can solve the problems of large amount of formwork, low construction efficiency, poor integrity, etc., to improve crack resistance, construction efficiency, and integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

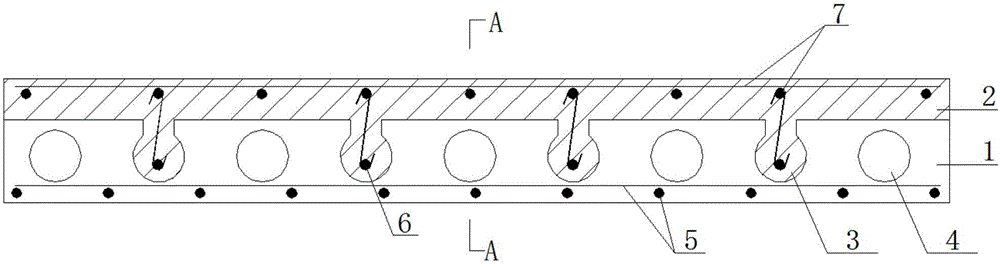

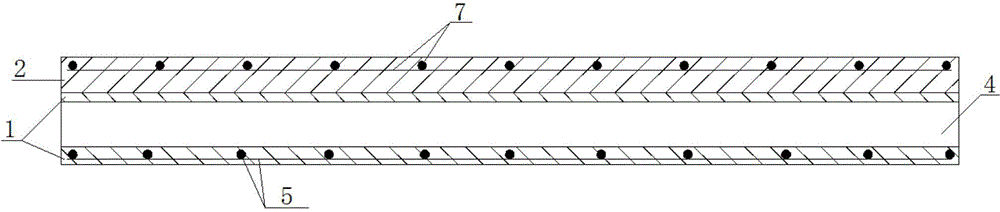

[0046] Such as figure 1 , figure 2 As shown, a hollow laminated floor slab includes a prefabricated hollow floor 1 and an upper cast-in-place slab 2. The hollow floor 1 is provided with full-length fully enclosed reserved holes 4 and semi-closed reserved holes 3 at intervals. The prefabricated hollow floor 1 Bottom plate steel bars 5 are laid out at intervals along the vertical and horizontal sides, semi-closed reserved holes 3 are pierced with internal steel bars 6, and reinforced concrete is poured above the hollow bottom plate 1 to form the upper cast-in-place slab 2. A plurality of sets of top steel bars 7 are arranged at intervals in the horizontal direction, and concrete is poured integrally above the hollow bottom slab 1 to form a hollow laminated floor slab.

[0047] The bottom plate reinforcement 5 is prestressed reinforcement or prestressed reinforcement and non-prestressed reinforcement arranged at intervals. The fully enclosed reserved hole 4 adopts a circular c...

Embodiment 2

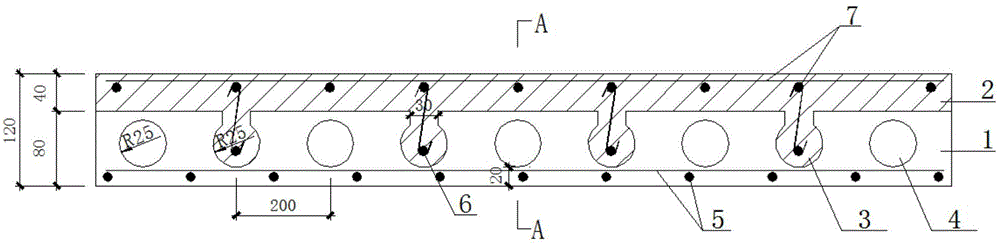

[0056] Such as Figure 4 , Figure 5 As shown, the opening end of the semi-closed reserved hole 3 in this embodiment is flush with the upper surface of the hollow bottom plate 1, and the diameter of the fully closed reserved hole 4 is smaller than that of the semi-closed reserved hole 3 . Other structures are the same as in Embodiment 1.

[0057] Such as Figure 6As shown, the thickness of the laminated slab in this embodiment is 120mm, the thickness of the prefabricated hollow bottom plate 1 is 80mm, the radius of the fully enclosed reserved hole 4 is 25mm, the radius of the semi-closed reserved hole 3 is 35mm, and the hole spacing is 300mm , the distance between the bottom of the reserved hole and the bottom plate is 20mm. Construction method and steps are the same as embodiment 1.

Embodiment 3

[0059] like Figure 7-11 As shown, a hollow laminated floor slab includes a prefabricated hollow floor 1, and the hollow floor 1 is provided with full-length fully-enclosed reserved holes at intervals. 1 includes multiple groups of plate ribs 9, each group of plate ribs 9 is divided by the cavity of the bottom plate, the bottom of the plate ribs 9 is provided with a plate rib reserved hole 10, the plate rib reserved hole 10 is pierced with steel bars 6 in the hole, Concrete is poured above the hollow bottom slab 1 to form an upper cast-in-place slab 2 , and multiple groups of top steel bars 7 are arranged at intervals along the vertical and horizontal directions on the upper cast-in-place slab 2 , and concrete is poured integrally above the hollow bottom slab 1 to form a hollow laminated floor slab.

[0060] The base plate reinforcement 5 adopts prestressed reinforcement or adopts the arrangement of prestressed reinforcement and non-prestressed reinforcement at intervals.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com