Broken drill pipe salvage device inside pile foundation hole

A salvage device and pile foundation hole technology, which is applied in the directions of earthwork drilling, wellbore/well components, etc., can solve the problems of increasing drilling cost, easy breakage of drill pipe, and large drilling engineering loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

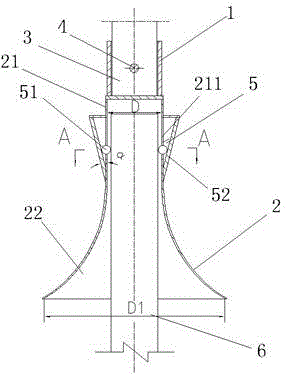

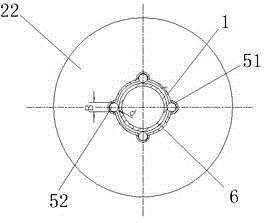

[0020] Such as figure 1 and figure 2 As shown, the clamping element of the drill pipe clamping mechanism in this embodiment is a steel ball and the storage cover is in the shape of a trumpet with a small top and a large bottom. The storage cover in this embodiment can also be a truncated cone with a small top and a large bottom.

[0021] The present invention includes a drill rod box 1 and a storage tube 2 fixedly connected sequentially from top to bottom. The lower end of the rotary drilling rig 3 in the drill rod box 1 is hinged, so that the present invention is very convenient to assemble and disassemble. The storage tube 2 is welded by the drill pipe sleeve 21 and the trumpet-shaped storage cover 22, which is convenient for receiving the broken drill pipe 6 . A drill pipe clamping mechanism 5 is arranged in the radial direction of the drill pipe sleeve 21, and the drill pipe clamping mechanism 5 includes four wedge-shaped clamping boxes 51 axially evenly distribut...

Embodiment 2

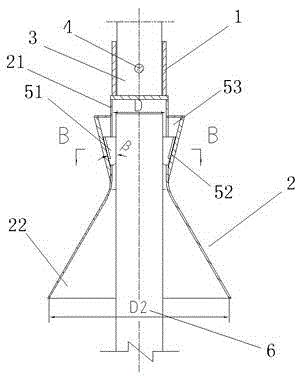

[0023] Such as image 3 and Figure 4 As shown, the wedge 53 of this embodiment is placed in the wedge-shaped clamping box 51 as a clamping element, and the bevel angle β of the wedge-shaped clamping box 51 is equal to the wedge angle α of the wedge-shaped clamping box 51, both of which are within 10°≤α≤13° Within the range, the wedge 53 is in a non-movable self-locking state, which can achieve the purpose of clamping the broken drill pipe 6. The cross section of the wedge 53 is a horizontal T-shape, and the horizontal side 531 of the horizontal T-shape stretches out from the axial notch 211 of the drill pipe sleeve 21, and the wedge 53 of the T-shaped structure can prevent it from moving outwards from the drill. Rod sleeve 21. In this embodiment, the storage cover 22 is shaped like a truncated cone with a small top and a large bottom, which is convenient for processing and forming; The shape of the storage cover 22 can also be a trumpet shape with a small top and a bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com