Oxidizing composite acid deep acidizing plugging removal method used for acidizing plugging removal of water injection well

A compound acid and oxidizing technology, which is used in wellbore/well components, earthwork drilling, and fluid production, etc., and can solve problems that cannot be solved by conventional acidification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The specific implementation process steps of the high-pressure under-injection well treatment technology in this embodiment are as follows:

[0053] (1) Preparation of active water

[0054] Table 1 Active water composition table (m 3 )

[0055] name

Weight percent (wt%)

Mass(Kg)

OP-10

5

250

[0056] (2) Prepare the main component acid solution

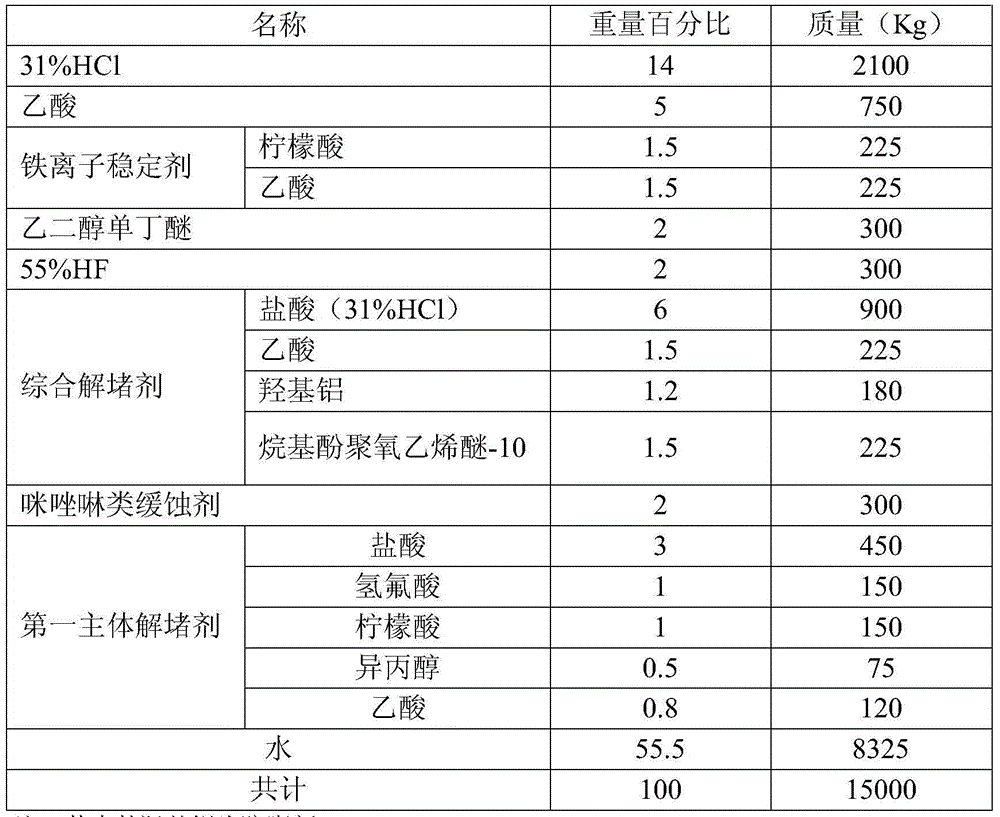

[0057] Based on the weight of the main component acid solution as 100%, 14wt% of hydrochloric acid, 5wt% of acetic acid, 2wt% of hydrofluoric acid, 3wt% of iron ion stabilizer, 2wt% of ethylene glycol monobutyl ether, and 10.2wt of comprehensive plugging remover %, 2wt% of imidazoline corrosion inhibitor, 6.3wt% of the first main body deblocking agent, and the rest of the water are mixed and stirred to prepare the main component acid solution, the components of the main component acid solution and their weight percentages See Table 2 for quality and quality.

[0058] Table 2 Main compo...

Embodiment 2

[0089] The oxidative compound acid deep acidification plugging removal method of the present invention is also used in Fang 162-185 and Yao 1-20 wells, and the effects before and after the implementation are shown in Table 7:

[0090] Table Qifang 162-185, Yao 1-20 well deep acidification measures effect statistics table

[0091]

[0092] The unit of pressure in the table is MPa, and the unit of water injection volume is m 3 .

[0093] According to the statistical data in Table 7, it can also be found that the method of the present invention has an obvious effect of reducing pressure and increasing injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com