Dual fuel engine combustion closed-loop control method based on analysis of heat release rate

A dual-fuel engine, closed-loop control technology, applied in engine control, combustion engine, internal combustion piston engine, etc., can solve the problems of in-cylinder combustion characteristics that cannot be considered and controlled, cylinder uniformity, power and emission reduction, etc. Achieve the effect of reducing work non-uniformity, improving emission characteristics, and optimizing power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

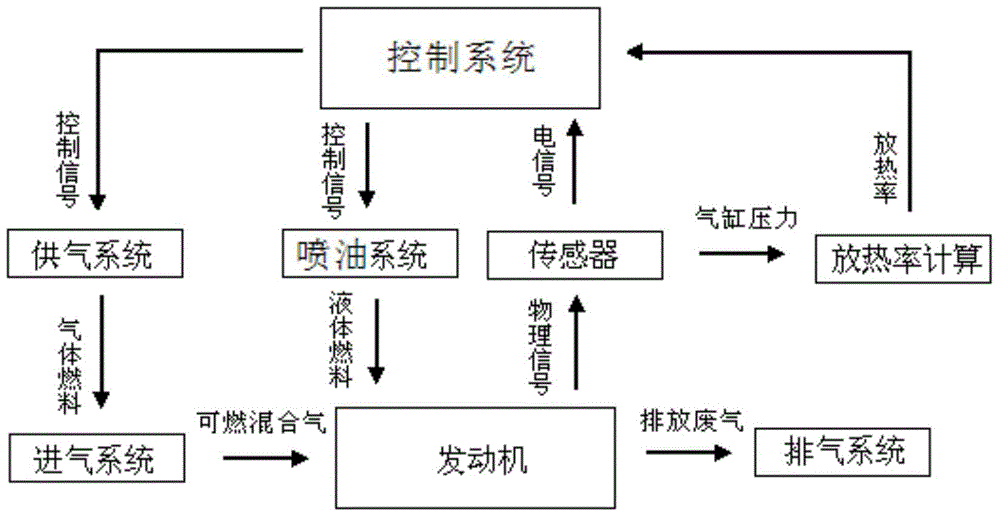

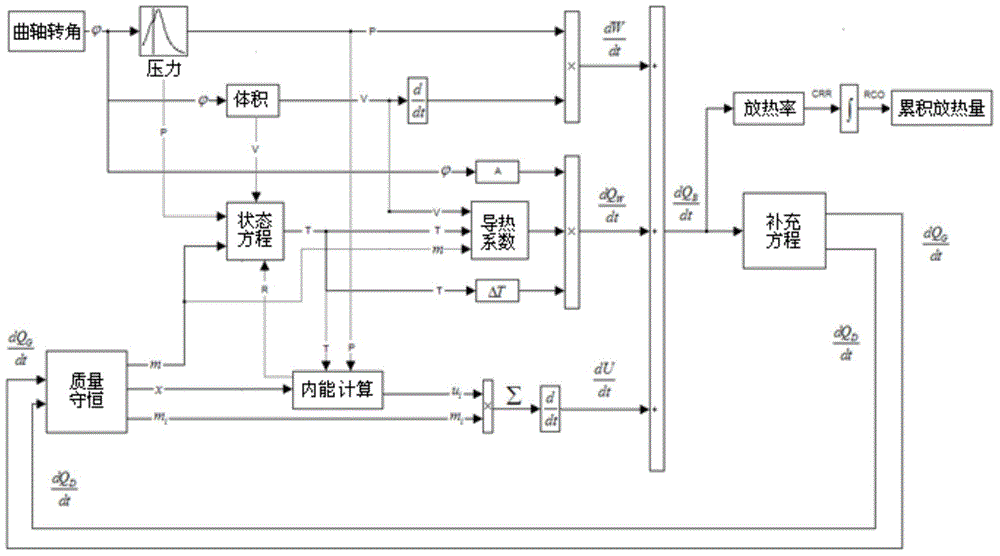

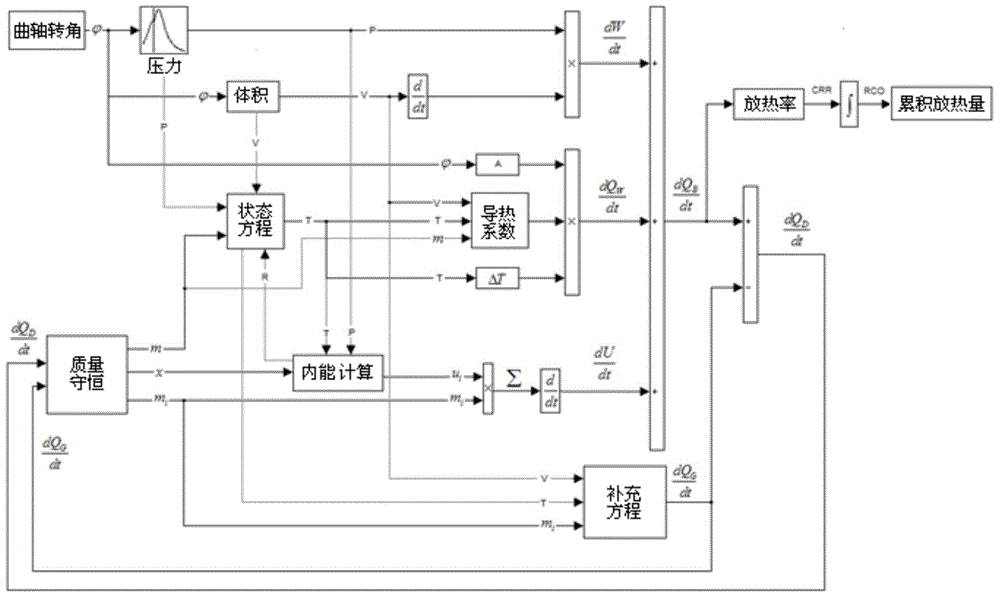

[0025] The invention discloses a dual-fuel engine combustion closed-loop control method based on heat release rate analysis, comprising the following steps: measuring important parameters of the dual-fuel engine through sensors; Heat release rate; Combined with test signals such as engine speed, knock and intake and exhaust temperature to analyze heat release rate characteristics; optimize control of each cylinder according to the analysis results. The method, based on engine testing and the laws of thermodynamics, provides closed-loop control of the combustion process inside a dual-fuel engine while the engine is running. The method can not only optimize the power, economy, and emission characteristics of the dual-fuel engine and improve the fuel utilization rate, but also can reduce the unevenness of work among the cylinders, make the engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com