A circulating preparative high performance liquid chromatograph with a multi-port valve

A technology of high performance liquid chromatography and cycle preparation, which is applied in the field of cycle preparation high performance liquid chromatography with a multi-port valve, which can solve the problems of complexity and eluent not being recycled, achieve large sample volume and improve separation effect , high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

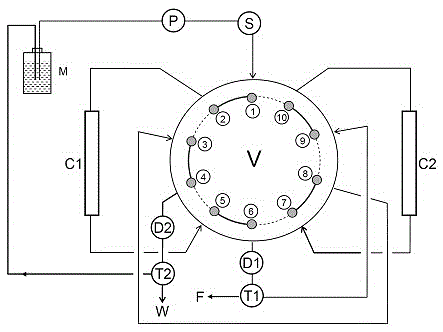

[0032] Example 1 as figure 1 As shown, a circulation preparation high performance liquid chromatograph with a multi-way valve and a method for preparing separation and purification, the circulation preparation high performance liquid chromatography is composed of a liquid reservoir M, a high pressure pump P, a sampler S, a chromatographic column It consists of C1 and C2, multi-way valve V, detectors D1 and D2, three-way switching valves T1 and T2, and liquid pipelines.

[0033] The eluent in the reservoir M is transported through the high-pressure pump P through the sampler S, and the sample in the carrier belt sampler S enters the chromatographic column C1 through the multi-port valve V for separation, and the effluent of the chromatographic column C1 passes through the multi-port The valve V enters the detector D1 for detection, and the components in the outflow curve that have reached the purity requirements are cut and extracted through the three-way switching valve T1, an...

Embodiment 2

[0038] Embodiment 2 According to the instrument design, connection and operation mode described in Embodiment 1, reversed-phase chromatographic separation is carried out:

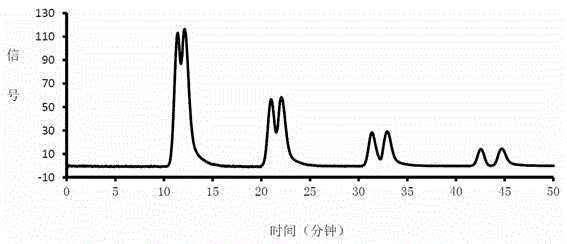

[0039] Reversed-phase chromatography is suitable for separating non-polar or medium-polar compounds, etc. For non-polar or medium-polar compound components with similar properties that are difficult to separate, a double-column circulation preparation high-performance liquid chromatography of the present invention can be used instrument for effective separation. According to the above connection and operation method, chromatographic columns C1 and C2 use stainless steel columns with a diameter of 25mm and a length of 200mm, and the columns are filled with 10mm reverse-phase C18 silica gel packing, and the methanol-water mixed solvent with a volume ratio of 80:20 is used as the eluent. image 3 In the separation process, the detector 1 records the output signal and the schematic diagram of component cutting....

Embodiment 3

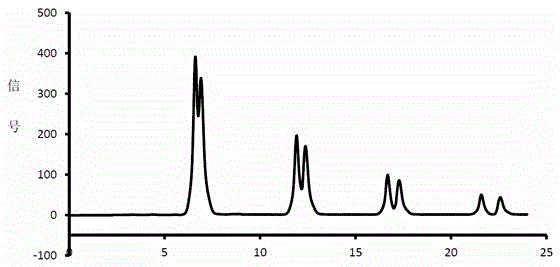

[0040] Embodiment 3 According to the instrument design, connection and operation mode described in Embodiment 1, the chromatographic column and chromatographic conditions in Embodiment 2 are used for separation, no cutting is performed during the separation process, and the corresponding peaks are collected after the separation is complete, and the cycle is repeated 4 times It can effectively separate daidzein and genistein with similar structures. Figure 4 Schematic diagram of the output signal recorded by detector 1 during the separation process. Since the eluent is only consumed when the peak components are collected, and the eluent is recycled at other times, the eluent consumed is very small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com