Preparation method of isoprothiolane suspending agent by employing water as solvent

A technology of rice blast spirit and suspending agent, which is applied in the field of preparation of rice blast spirit suspension agent, can solve the problems of serious environmental pollution, air pollution, harm to operators and environmental safety, etc., and achieves convenient use, safe storage, transportation and use, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The preparation method of the rice blasting suspension using water as the solvent of the present invention includes the following steps:

[0012] (1) Heat the deionized water to 30~80℃, add it into the high shear kettle and stir, add the dispersant until it is completely dissolved;

[0013] (2) According to rice blasting agent 10-60%, wetting agent 0.1-10%, thickening agent 0.1-10%, antifreeze 0.1-8%, defoaming agent 0.1-5%, dispersing agent 0.1-10%, Deionized water and make up the percentage, put the above raw materials into the high-shear kettle to make slurry, and the high-speed shear time is 0.5-10h to cool down;

[0014] (3) The above-mentioned slurry is pumped into the sand mill through the pipeline and diaphragm pump for high-speed grinding, and the temperature of the circulating fluid of the sand mill is maintained at -25℃~25℃;

[0015] (4) The sand mill is a series of multiple sand mills to make a suspending agent, so that the particle diameter of the suspending agent ...

Embodiment 1

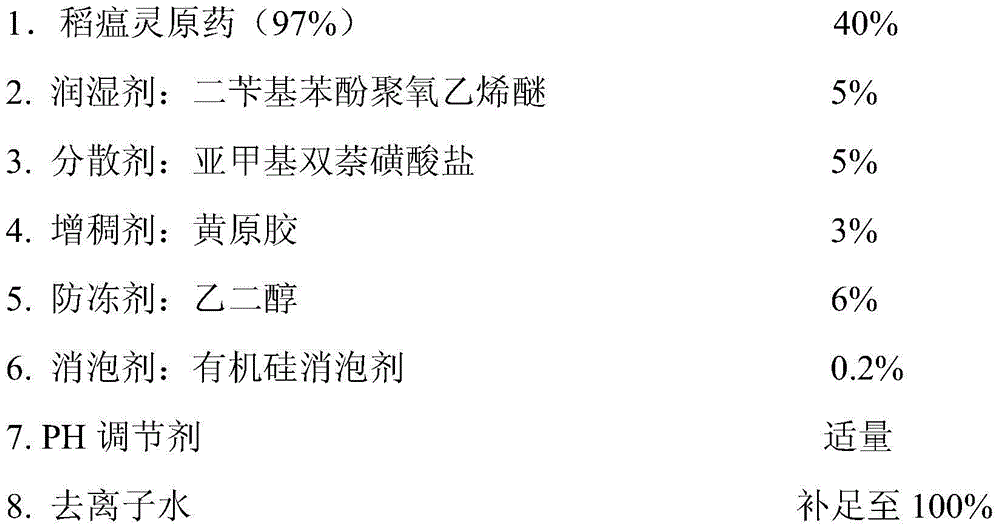

[0021] Example 1 40% rice blast spirit suspension

[0022]

[0023] The preparation method of 40% rice blasting suspension agent: Weigh various raw materials according to the above ratio, then heat the deionized water to 35℃, add the deionized water into the high shear kettle, and mix the dispersant methylene Add the bis-naphthalene sulfonate, and after it is completely dissolved, put the rice blasting agent, wetting agent, thickener, antifreeze, and defoamer into the high-shear kettle, and high-speed shear for 30-40 minutes. The temperature is reduced to 15°C, and then the slurry is pumped into the sander through a pipeline and a diaphragm pump for high-speed grinding, and the circulating water temperature of the sand mill is maintained at 15°C. Three sanders are operated in series. Make the particle diameter of the suspending agent below 4μm and adjust the PH value to 6.5 to obtain a 40% rice blasting suspension.

Embodiment 2

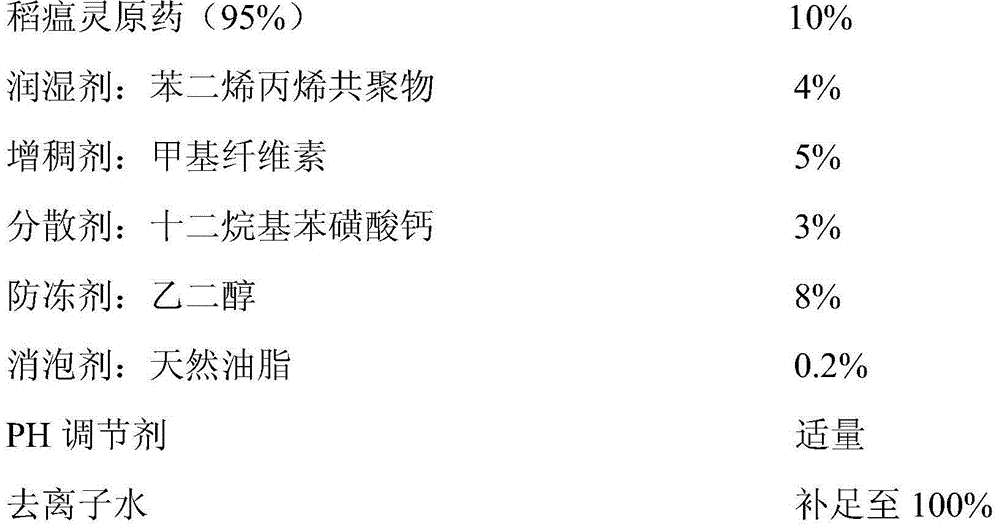

[0024] Example 2 10% rice blast spirit suspension

[0025]

[0026] The specific operation steps are the same as in Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com