Rectifying and spray-freezing drying method for preparing polyethylene oligomer powder

A technology of freeze spraying and drying method, which is applied in the direction of fractionation, liquid separation into beads and granulation, etc. It can solve the problems of complex operation process, low thermal efficiency, and low volume heat transfer coefficient, and achieve the effect of simple operation and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

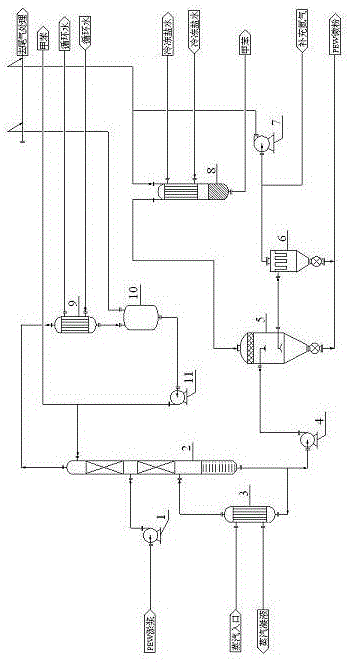

[0021] Such as figure 1 As shown, the "rectification + freeze spray" drying method for preparing polyethylene oligomer powder includes the following steps:

[0022] ⑴Transfer the polyethylene wax solution to the middle of the rectification tower 2 through the slurry pump 1; at the same time, the saturated steam with a temperature of 158℃ passes through the distillation tower 2 bottom reboiler 3 to indirectly exchange heat with the polyethylene wax solution; Under the constraint of driving force and phase equilibrium, the solvent toluene is separated from the polyethylene wax, the polyethylene wax melt with a purity of ≥99.9% is collected to the bottom of the rectification tower 2, and the solvent toluene is extracted from the top of the rectification tower 2.

[0023] ⑵The solvent toluene enters the top condenser 9, and at the same time, the cooling medium is input to the top condenser 9 for indirect heat exchange, so that the solvent toluene is cooled to a liquid state and then di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com