Prepacked ready-to-eat fish ball and processing method thereof

A pre-packaging and fish egg technology, which is applied in the fields of baked food, food preparation, food science, etc., can solve the problems that the technology is difficult to achieve at the same time, and achieve the effect of maintaining the texture of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

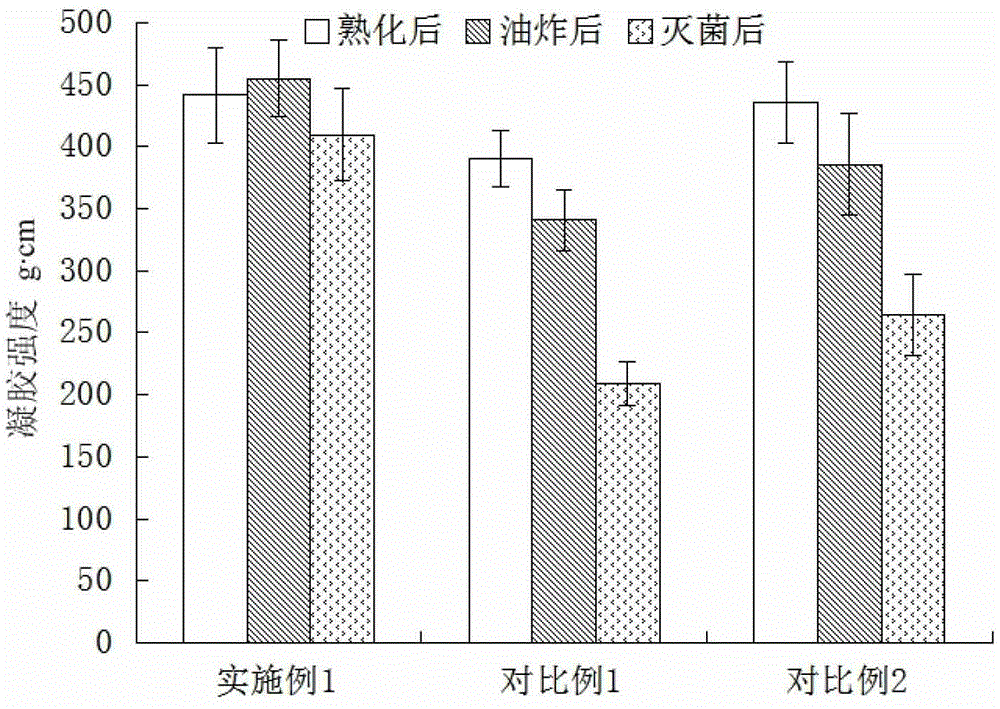

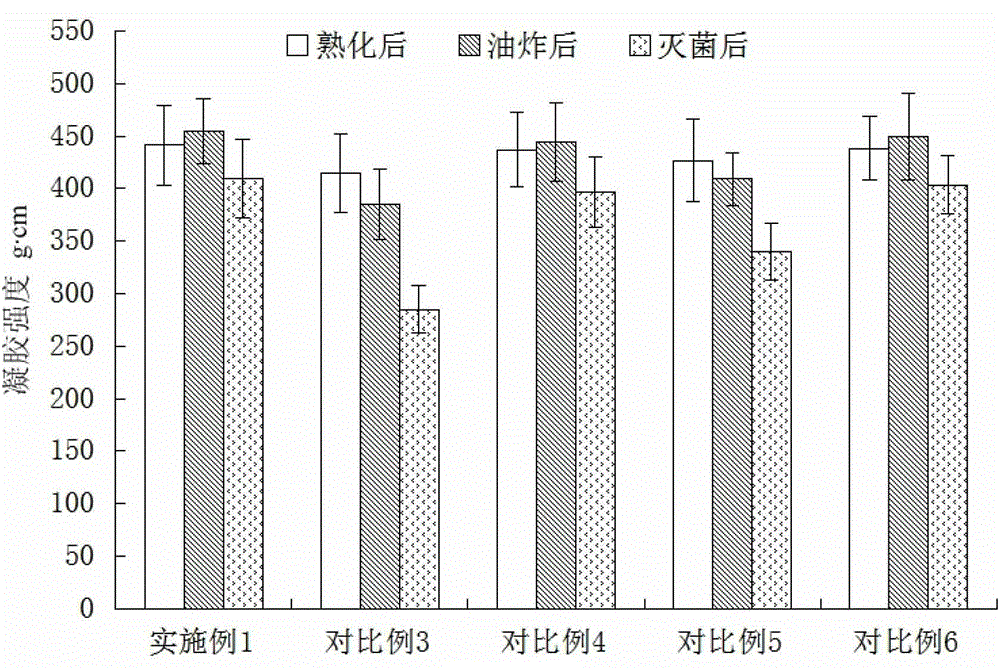

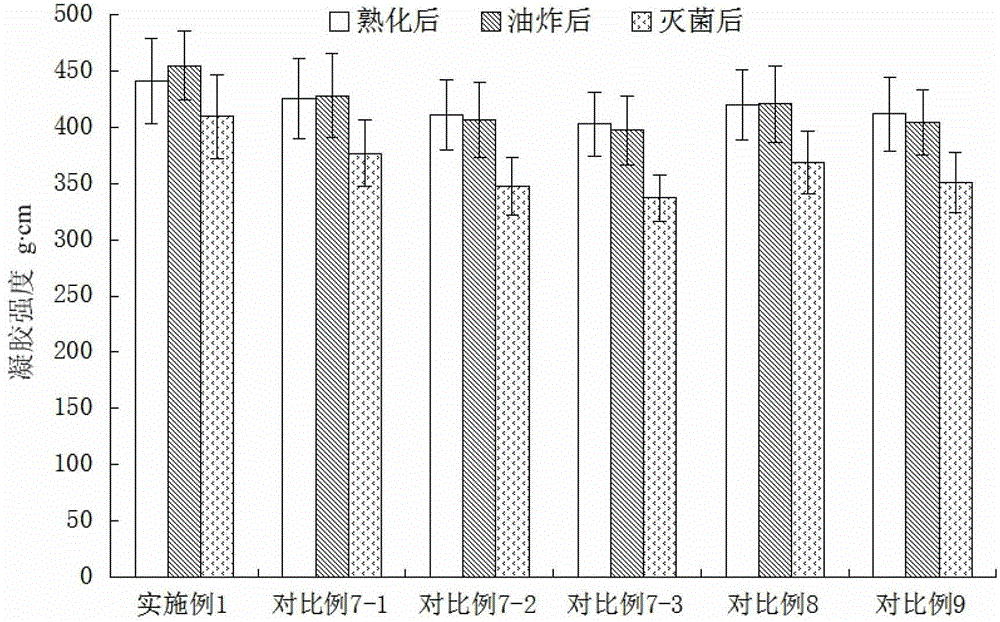

Examples

Embodiment 1

[0056] The proportioning of prepackaged ready-to-eat fish eggs, in percentage by weight, consists of: surimi (frozen surimi) 70%, compound phosphate 0.3%, edible salt 0.5%, white granulated sugar 1.5%, monosodium glutamate 0.5%, xylose 0.15% %, glucose 0.2%, curdlan gum powder 1%, high amylose corn starch 4%, MTG modified gluten powder 6%, water 10%, other accessories (fat meat, ginger and garlic), spices (pepper powder), seasoning Ingredients and food flavors add up to 5.85%.

[0057] The processing method of prepackaged instant fish eggs is:

[0058] 0) Pretreatment: mix curdlan rubber powder, high amylose corn starch, MTG modified gluten powder, and water according to the above ratio, and perform mechanical shearing operation with a high-speed emulsifier at a shaft speed of 7000r / min for 3 minutes, and then use The food heating and stirring tank is heated and stirred at a shaft speed of 150r / min to 65±1°C, and maintained for 4 minutes to obtain a mixed slurry; cooled to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com