Stirrer for chemical production

A chemical production and agitator technology, applied in chemical instruments and methods, mixers with rotating agitating devices, chemical/physical/physicochemical fixed reactors, etc., can solve the difficulties in processing parts, low work efficiency, and labor-intensive Material resources and other issues, to achieve the effect of increased product yield, low processing cost, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

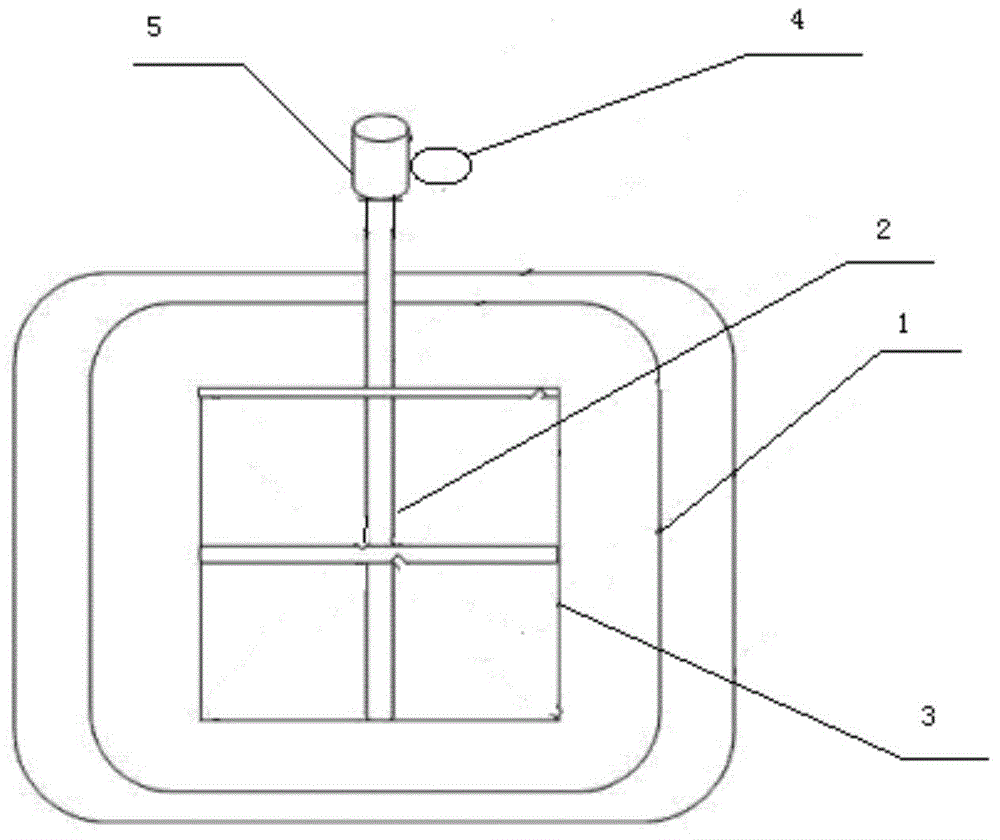

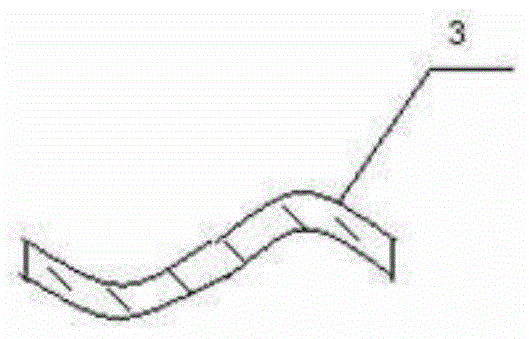

[0013] The present invention provides an agitator for chemical production, which is characterized in that: it includes an agitator main shaft 2 and a stirring blade 3 placed in a reaction tank 1; the upper part of the agitator main shaft 2 is coaxially provided with a motor 5 with a frequency converter 4; The agitator main shaft 2 is provided with a stirring blade 3; the agitating blade 3 is connected in a square shape, and the agitating blade 3 itself is helical; the agitator increases the contact surface between the agitating blade 3 and the object to be agitated , and it is not easy to adhere to the reactant; the reaction efficiency is high, and the product yield is improved.

[0014] The reaction tank 1 is made of stainless steel, wear-resistant and practical, and prolongs the service life of the reaction tank.

[0015] An embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com