Production method for color-reversion-resisting chilled fresh food tailored flour

A production method and special flour technology, which is applied in the field of wheat flour production, can solve the problems of cold and fresh food color change, protein content, starch strength unevenness, seriousness, etc., and achieve the effect of reducing the degree of color change, controlling color and internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The production method of the anti-reflection cold fresh food special powder of the present invention, it comprises the following steps:

[0013] In the first step, four kinds of wheats are selected: Zhengmai 7698, Aikang 58, Space 6, and Huapei 8. According to the evaluation value equation 75X+(100-X)=60×100, the weight ratio of the four kinds of wheat is obtained as Zheng Mai 7698: Aikang 58: Space No. 6: Huapei No. 8=3:2:1:1;

[0014] In the second step, the mixed wheat used in the first step is cleaned of impurities according to the process of sieving, stone removal, selection, threshing, and then sieving. The stone removal machine can be a specific gravity classification stone removal machine;

[0015] The third step is to add 5% water to the cleaned wheat, and moisten the wheat for 24 hours at a temperature of 25°C, so that the moisture content in the wheat before grinding reaches 15%;

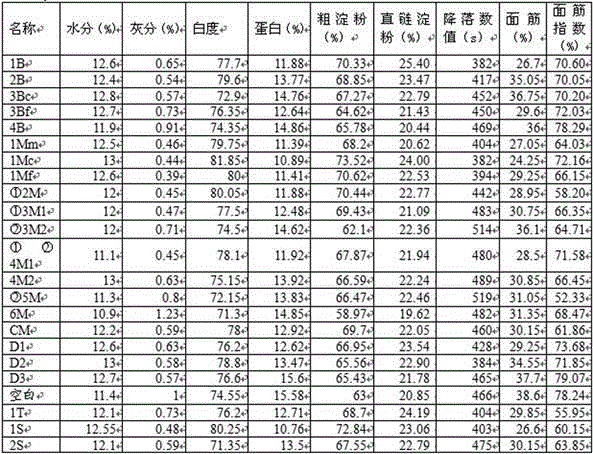

[0016] In the fourth step, after the processed wheat is graded and milled acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com