Two-dimensional ultrasound vibration platform

A two-dimensional ultrasonic vibration and platform technology, which is applied in the direction of fluid, solid separation, and filter screens using vibration, can solve the problems of large spindle changes and poor transplantability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

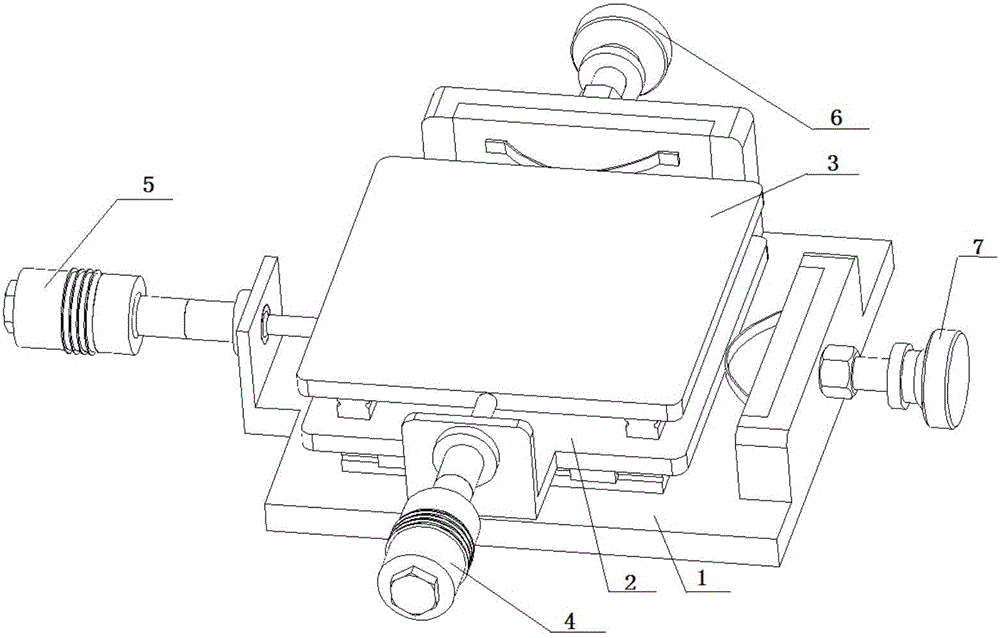

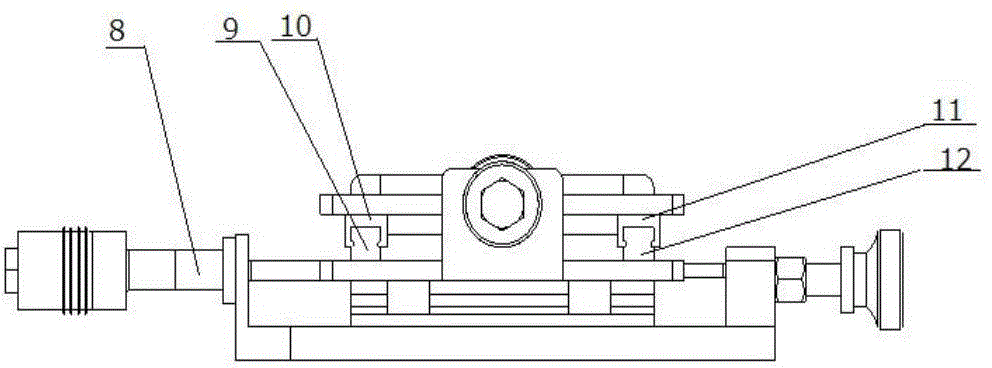

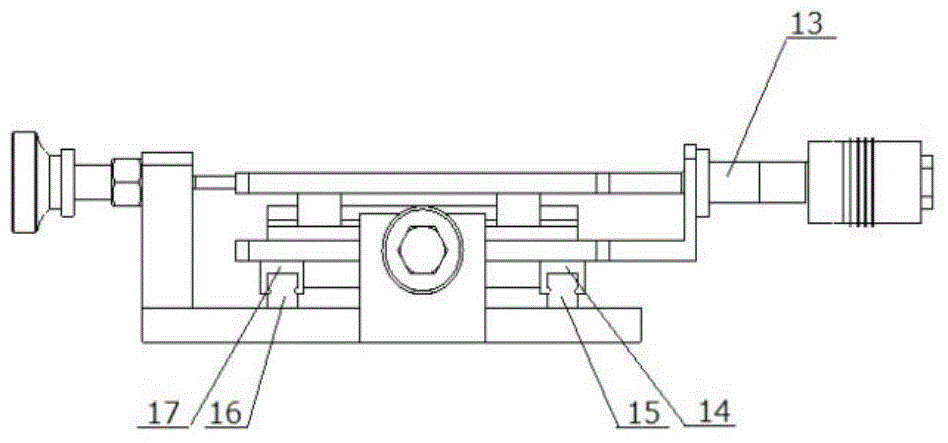

[0020] see Figure 1 to Figure 6 , a two-dimensional ultrasonic vibration platform, including a bearing plate 1, a lower vibration plate 2 and an upper vibration plate 3 arranged in sequence from bottom to top.

[0021] The lower vibrating plate 2 is connected to the bearing plate 1 through the X-direction linear motion guide rail; in this embodiment, there are two X-direction linear motion guide rails, one is composed of an X-direction track 15 and a slider 14, and the other is composed of an X-direction linear motion guide rail. X direction track 16 and slide block 17 are formed.

[0022] In the X direction, an X-direction vibrator is connected to one side of the lower vibrating plate 2, and an X-direction arched spring piece 19 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com