Method for preparing lithium phosphate powder

A lithium phosphide and powder technology is applied in the field of preparing lithium phosphide powder, which can solve the problems of low product purity, poor batch performance, and difficulty in realizing industrialized production, and achieve the effect of high purity and good product batches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

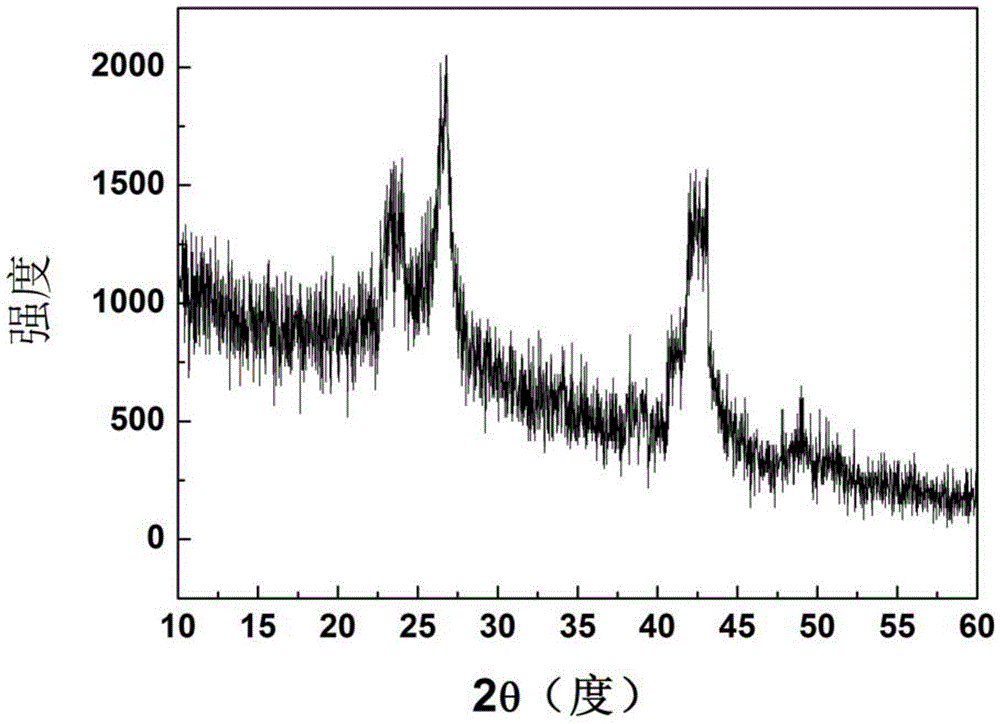

[0026] The red phosphorus powder was dried in a vacuum oven at 80°C for 6h. Under the protection of an argon atmosphere, 0.31 g of red phosphorus powder and 0.24 g of lithium hydride powder were uniformly mixed and then added to a ball mill jar. Then put the balls into the ball mill jar and seal it. The ratio of the total mass of grinding balls to the total mass of materials is 40:1. Under the condition of 25° C., the ball milling tank was continuously ball milled at a speed of 500 r / min for 32 hours, and the obtained powder was lithium phosphide powder. figure 1 Its corresponding XRD diffraction pattern, compared with the standard card, shows that the obtained product is pure phase lithium phosphide, and no other impurities exist.

Embodiment 2

[0028] The red phosphorus powder was dried in a vacuum oven at 60°C for 10 h. Under the protection of nitrogen atmosphere, 4.6g of red phosphorus powder and 2.6g of lithium hydride powder were uniformly mixed and then added to the ball mill jar. Then put the balls into the ball mill jar and seal it. The ratio of the total mass of grinding balls to the total mass of materials is 80:1. Under the condition of 48° C., the ball milling tank was continuously ball milled at a speed of 450 r / min for 24 hours, and the obtained powder was lithium phosphide powder.

Embodiment 3

[0030] Dry the white phosphorous powder in a vacuum oven at 75°C for 12 hours. Under the protection of an argon atmosphere, 3.1 g of white phosphorus powder and 2.8 g of lithium hydride powder were uniformly mixed and then added to a ball mill jar. Then put the balls into the ball mill jar and seal it. The ratio of the total mass of grinding balls to the total mass of materials is 60:1. Under the condition of 60° C., the ball mill jar was continuously ball milled at a speed of 500 r / min for 32 hours, and the obtained powder was lithium phosphide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com