Full-automatic thermal cycler hot cover

A thermal cycler, fully automatic technology, used in medical testing, biological fields, can solve problems such as burns, difficult integration, etc., to achieve the effects of easy assembly, uniform force, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

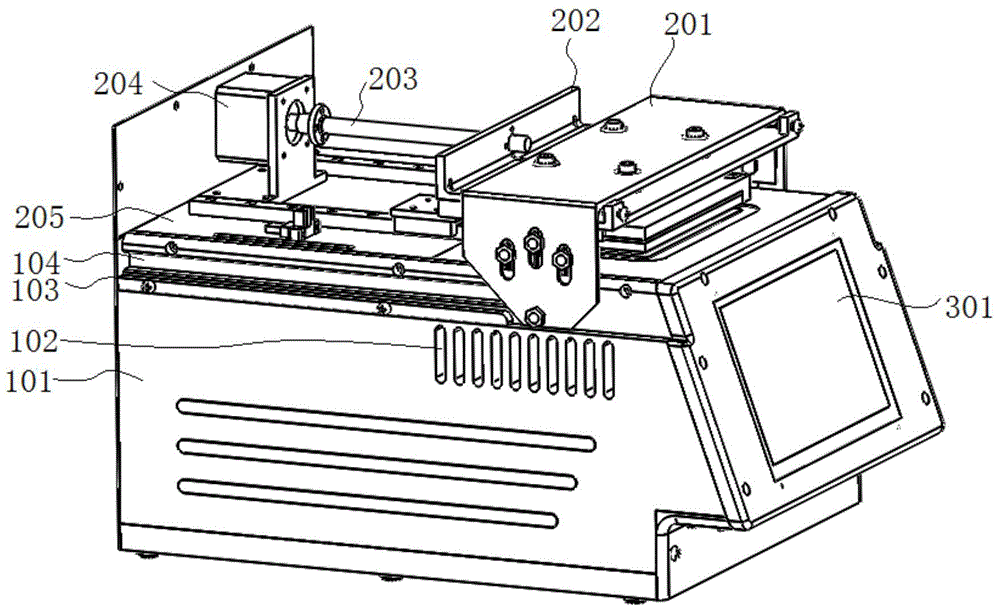

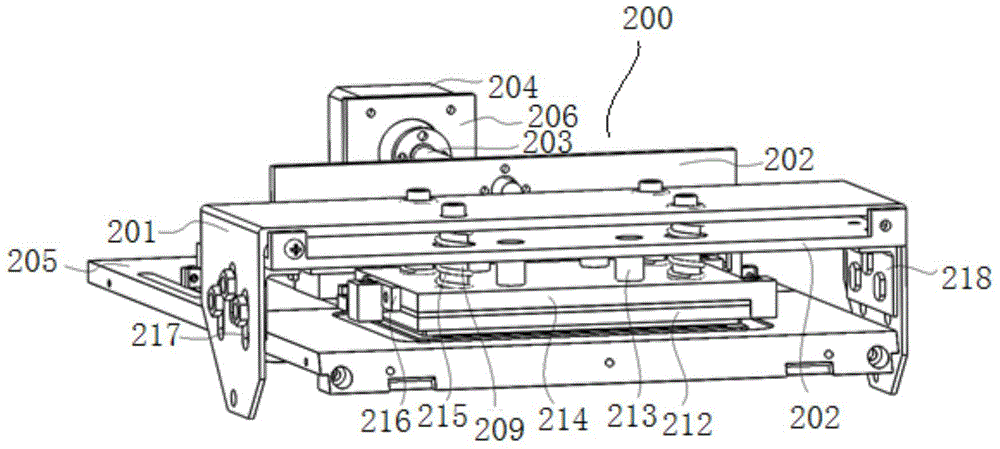

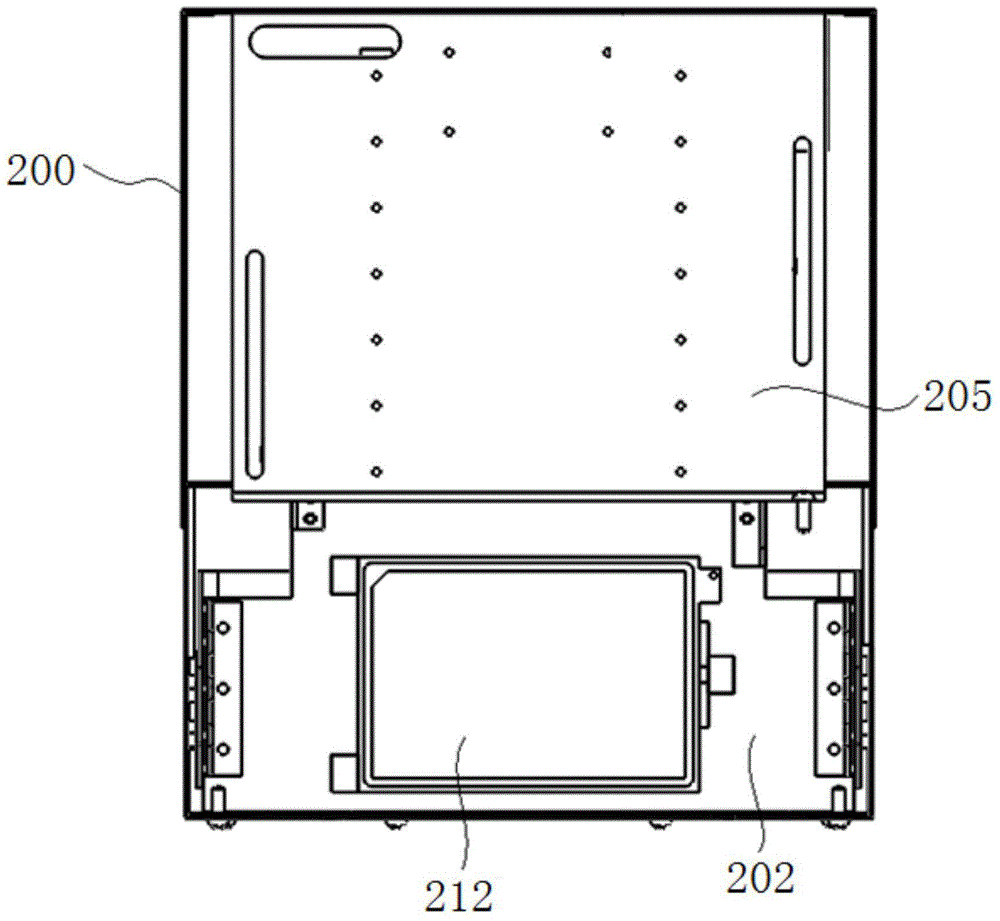

[0024] Below in conjunction with embodiment and attached Figure 1-7 The present invention is further explained. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0025] This implementation case is combined with the entire PCR thermal cycler and illustrated through a PCR amplification experiment operation. The experiment starts, the thermal cycler is powered on, the touch screen 301 is initialized, and the hot cover opening command button on the touch screen is clicked. If the fully automatic thermal cycler thermal cover 200 is originally opened, the drive motor 204 will not work, and the user will install the hot cover to be expanded. Place the 96-well plate or individual PCR tubes with the enriched samples in the heat trap. Click the hot cover off command button to drive the motor 204 to rotate and drive the threaded screw 203 to rotate. The threaded lead screw 203 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com