Preparation method of small water turtle anti-tumor polypeptide

An anti-tumor and money technology, which is applied in the field of preparation of anti-tumor polypeptides of the tortoise, can solve the problems of large toxic and side effects and unsatisfactory treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take 5 g of golden turtle meat and ultrapure water, mix and stir to prepare a mixed solution with a concentration of 10% (w / v), add trypsin for enzymatic hydrolysis, the hydrolysis conditions are: PH=7, enzymatic hydrolysis temperature 35℃, enzymatic hydrolysis time is 5 hours, and the concentration ratio of enzyme to substrate is 0.2% (w / w). In this process, 0.05 mol / L NaOH and HCl are used to adjust the pH value of the reaction system, and control the pH value between pH±0.05. After the enzymolysis is completed, the enzyme is inactivated in 80℃ water for 10 minutes, cooled to room temperature, and the enzymatic hydrolysis The solution was centrifuged at 7000 r / min for 30 min, and the supernatant was taken.

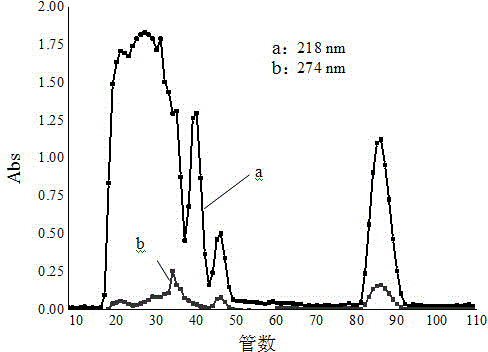

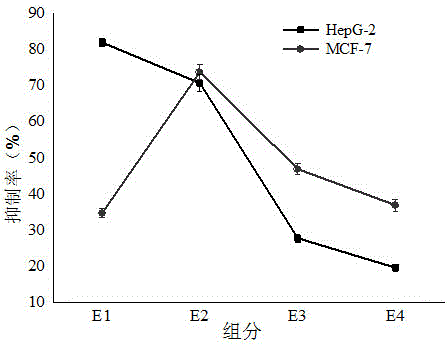

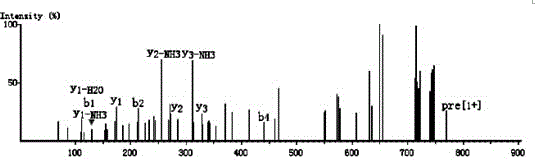

[0027] (2) Take the enzymatic hydrolysate obtained in step (1) and use the ultrafiltration membranes with molecular weight cutoffs of 10 KD, 5 KD and 3 KD to filter (CO 2 The pressure is 0.1 Mpa at room temperature), so as to obtain the enzymatic hydrolysate of P...

Embodiment 2

[0031] (1) Take 10 g of golden turtle meat and ultrapure water, mix and stir to prepare a mixed solution with a concentration of 15% (w / v), add trypsin for enzymatic hydrolysis, the hydrolysis conditions are: PH=8, enzymatic hydrolysis temperature 30℃, enzymolysis time is 10 h, the concentration ratio of enzyme and substrate is 0.1% (w / w). During this process, 0.1 mol / L NaOH and HCl were used to adjust the pH value of the reaction system, and the pH value was controlled between pH ± 0.05. After enzymolysis, the enzyme was inactivated in 95℃ water for 15 min, cooled to room temperature, and the enzymatic hydrolysis The solution was centrifuged at 6000 r / min for 35 min, and the supernatant was taken.

[0032] (2) Take the enzymatic hydrolysate obtained in step (1) and use the ultrafiltration membranes with molecular weight cutoffs of 10 KD, 5 KD and 3 KD to filter (CO 2 The pressure is 0.22 Mpa at room temperature), so as to obtain the enzymatic hydrolysate of P. vulgaris polypepti...

Embodiment 3

[0035] (1) Mix 18 g of golden turtle meat and ultrapure water and stir to prepare a mixed solution with a concentration of 30% (w / v). Add trypsin for enzymatic hydrolysis. The hydrolysis conditions are: PH=9, enzymatic hydrolysis temperature 60°C, enzymolysis time 15 h, concentration ratio of enzyme to substrate is 0.5% (w / w). During the process, 0.2 mol / L NaOH and HCl were used to adjust the pH value of the reaction system, and the pH value was controlled between pH ± 0.05. After enzymolysis, the enzyme was inactivated in water at 100°C for 20 min, cooled to room temperature, and the enzymatic hydrolysis The solution was centrifuged at 8000 r / min for 60 min, and the supernatant was taken.

[0036] (2) Take the enzymatic hydrolysate obtained in step (1) and use the ultrafiltration membranes with molecular weight cutoffs of 10 KD, 5 KD and 3 KD to filter (CO 2 The pressure is 0.25 Mpa at room temperature), so as to obtain the enzymatic hydrolysate of the golden tortoise polypeptid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com