Method for preparing sintered ore by using high-chromium-type vanadium-titanium mixture

A mixed material, high chromium type technology, applied in the field of metallurgy, can solve the problem of low material layer height, achieve the effect of no decrease in air permeability and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

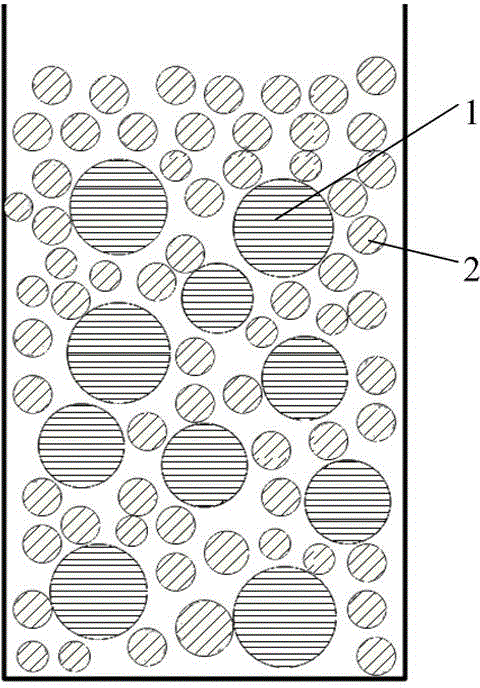

Image

Examples

Embodiment 1

[0026] Prepare high-chromium vanadium-titanium magnetite concentrate, iron ore powder and returned ore as raw materials, screen out the part with a particle size of <0.106mm as fine material, and the rest as coarse material; high-chromium vanadium-titanium magnetite concentrate accounts for 10% of the raw materials , the returned ore accounts for 30% of the total weight, and the rest is iron ore powder;

[0027] Take by weighing 20% of the fine material as the small pellet raw material; mix the small pellet raw material with quicklime and coke powder evenly, wherein the consumption of quick lime is 0.5% of the total weight of the small pellet raw material, and the consumption of coke powder is pellet 0.5% of the total weight of the pellet raw materials; then use a disc pelletizer to prepare small pellets with a particle size of 5-8mm;

[0028] The rest of the fine material and all the coarse material are used as the mixture raw material; the mixture raw material is evenly mi...

Embodiment 2

[0032] Method is with embodiment 1, and difference is:

[0033] (1) Among the raw materials, high-chromium vanadium-titanium magnetite concentrate accounts for 30%, and the returned ore accounts for 20% of the total weight;

[0034] (2) Weigh 40% of the fine material as the pellet raw material; the consumption of quicklime is 1.0% of the total weight of the pellet raw material, and the consumption of coke powder is 1.0% of the total weight of the pellet raw material;

[0035] (3) The amount of quicklime in the mixture raw material is 2.5% of the total weight of the mixture raw material, the amount of limestone is 2.0% of the total weight of the mixture raw material, the amount of magnesite is 1.0% of the total weight of the mixture raw material, coke powder The dosage is 4.5% of the total weight of the raw materials of the mixture; then the mixture is made with a disc pelletizer, and the mixture with a particle size of +3mm accounts for more than 60% of the total weight;

[0...

Embodiment 3

[0039] Method is with embodiment 1, and difference is:

[0040] (1) Among the raw materials, the high-chromium vanadium-titanium magnetite concentrate accounts for 50%, and the returned ore accounts for 15% of the total weight;

[0041] (2) Weigh 60% of the fine material as the pellet raw material; the consumption of quicklime is 3.0% of the total weight of the pellet raw material, and the consumption of coke powder is 2.0% of the total weight of the pellet raw material;

[0042] (3) The amount of quicklime in the mixture raw material is 1% of the total weight of the mixture raw material, the amount of limestone is 4.0% of the total weight of the mixture raw material, the amount of magnesite is 3.0% of the total weight of the mixture raw material, coke powder The dosage is 3% of the total weight of the raw materials of the mixture; then the mixture is made by a disc pelletizer, and the particle size +3mm in the mixture accounts for more than 60% of the total weight;

[0043] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com