Method for preparing sintered ore by sintering ilmenite concentrate

A technology of ilmenite concentrate and vanadium-titanium iron concentrate, which is applied in the field of metallurgy, can solve the problems of less liquid phase formation, low sinter strength, and poor pulverization, so as to improve strength and pulverization performance, and optimize operating parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

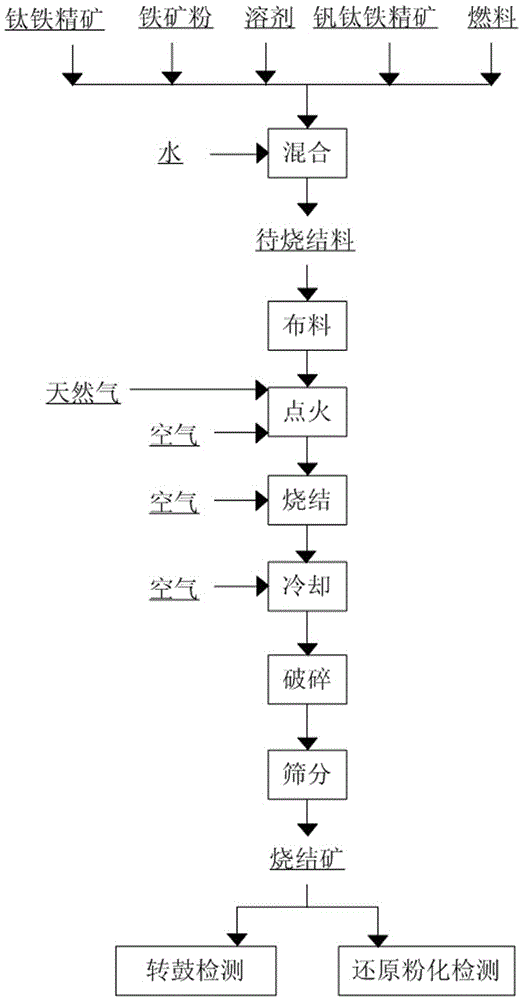

Image

Examples

Embodiment 1

[0030] Prepare raw materials, wherein by weight percentage, ilmenite concentrate accounts for 40%, vanadium-titanium iron concentrate accounts for 35%, iron ore powder accounts for 5%, flux accounts for 15%, and fuel accounts for 5%;

[0031] Add water to all raw materials and put them into a mixer for mixing. The amount of water added is 5% of the total weight of all raw materials. After mixing evenly, a material to be sintered with a particle size of 3-5mm is obtained;

[0032] After distributing the material to be sintered in the sintering machine, sintering is carried out on the sintering machine with ignition and ventilation; the sintering ignition temperature is 1050°C, and the ignition negative pressure is 6KPa. The negative pressure is 11KPa;

[0033] When the temperature of the sintering waste gas drops to ≤100°C, the sintered material is taken out, crushed and sieved to obtain a sintered ore with a drum index of 70% and a reducing pulverization index of 50%.

Embodiment 2

[0035] Method is with embodiment 1, and difference is:

[0036] (1) Raw materials, of which ilmenite concentrate accounts for 70% by weight, vanadium-titanium iron concentrate accounts for 5%, iron ore powder accounts for 13%, flux accounts for 8%, and fuel accounts for 4%;

[0037] (2) The amount of water added is 3% of the total weight of all raw materials;

[0038] (3) The sintering ignition temperature is 1150°C, the ignition negative pressure is 5KPa, the sintering is completed when the temperature of the sintering exhaust gas begins to drop, the sintering end temperature is 400°C, and the sintering negative pressure is 12KPa;

[0039] (4) The drum index of sinter is 60%, and the reducing pulverization index is 65%.

Embodiment 3

[0041] Method is with embodiment 1, and difference is:

[0042] (1) Raw materials, of which 45% by weight of ilmenite concentrate, 25% of vanadium-titanium iron concentrate, 15% of iron ore powder, 10.5% of flux, and 4.5% of fuel;

[0043] (2) The amount of water added is 4% of the total weight of all raw materials;

[0044] (3) The sintering ignition temperature is 1250°C, and the ignition negative pressure is 5KPa. When the sintering waste gas temperature begins to drop, the sintering is completed. The sintering end temperature is 450°C, and the sintering negative pressure is 11KPa;

[0045] (4) The drum index of sinter is 65%, and the reduction pulverization index is 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com