Plate air preheater with fully-glass-lined channel

An air preheater and glass-lined technology, which is applied in the direction of heat exchanger shell, heat exchanger sealing device, heat exchange equipment, etc., can solve the corrosion damage of metal heat exchange elements, smoke or air leakage, and short service life And other problems, to achieve the effect of prolonging service life, improving heat transfer efficiency, and not easy to accumulate dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

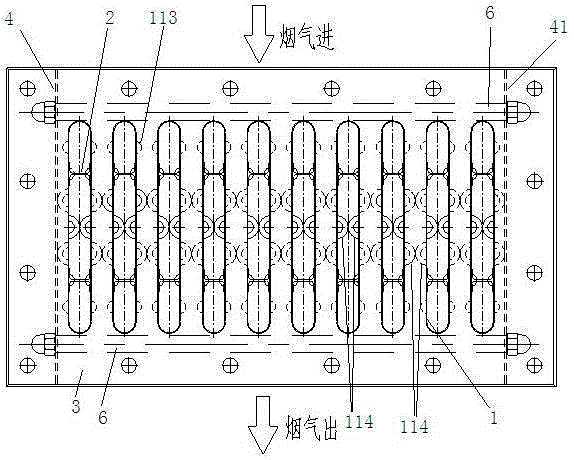

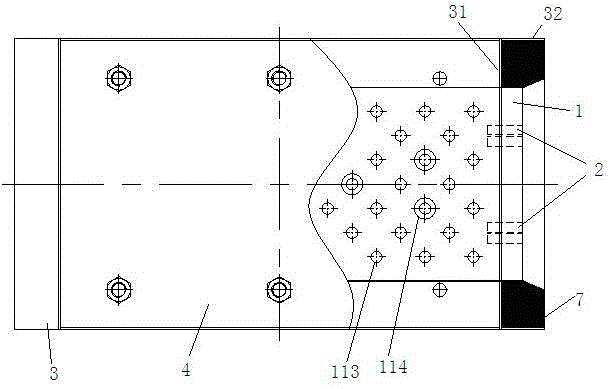

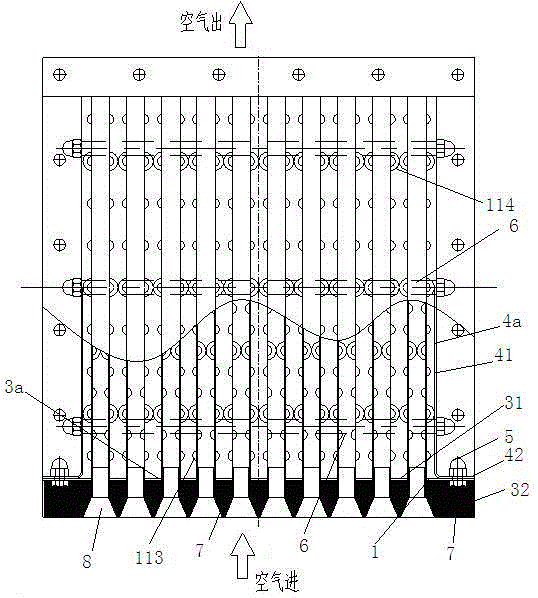

[0023] See Figure 1 to Figure 7 . A plate-type air preheater with fully glass-lined channels according to an embodiment of the present invention includes a plurality of plate tubes 1 , a pair of first support seats 3 , a pair of second support seats 4 and a plurality of positioning bolts 6 .

[0024] The plurality of plate tubes 1 are arranged in at least one row, and the arrangement of one row of plate tubes 1 is only used as an example in the figure. Each plate tube 1 is welded by a pair of oppositely arranged plates 11. All the plates 11 of the plate air preheater have the same structure, and each plate 11 includes a plate body 111 and a Two ends of the sheet body are a pair of folded edges 112 obliquely bent toward one side of the sheet body. The inner surface and the outer surface of each plate 11 are provided with a plurality of spoiler protrusions 113, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com