Internal thermal coupling rectification control method and device based on temperature wave model predictive control

A model predictive control and internal thermal coupling technology, applied in adaptive control, general control system, control/regulation system, etc., can solve problems such as poor interference suppression capability, low sensitivity to noise, and low online operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The present invention will be further described below in conjunction with accompanying drawing.

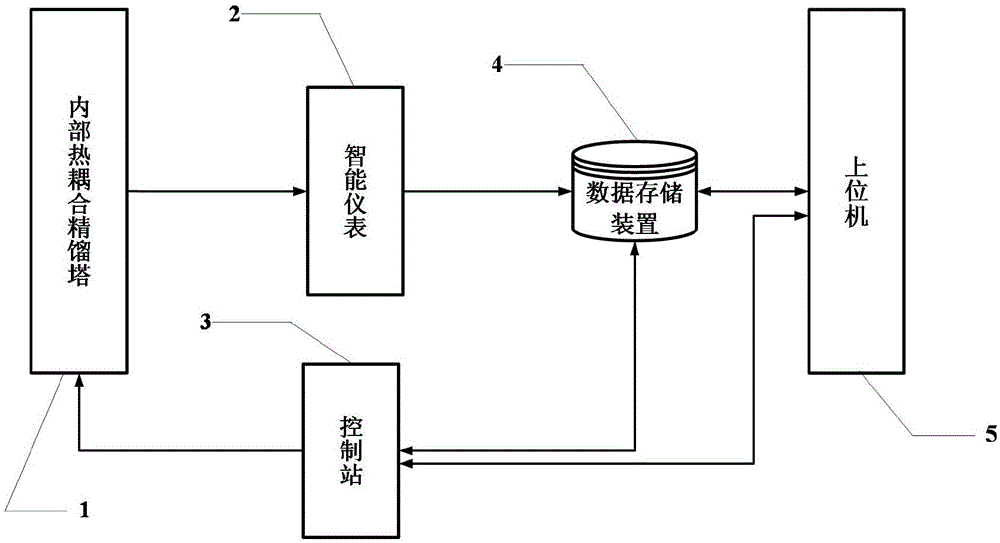

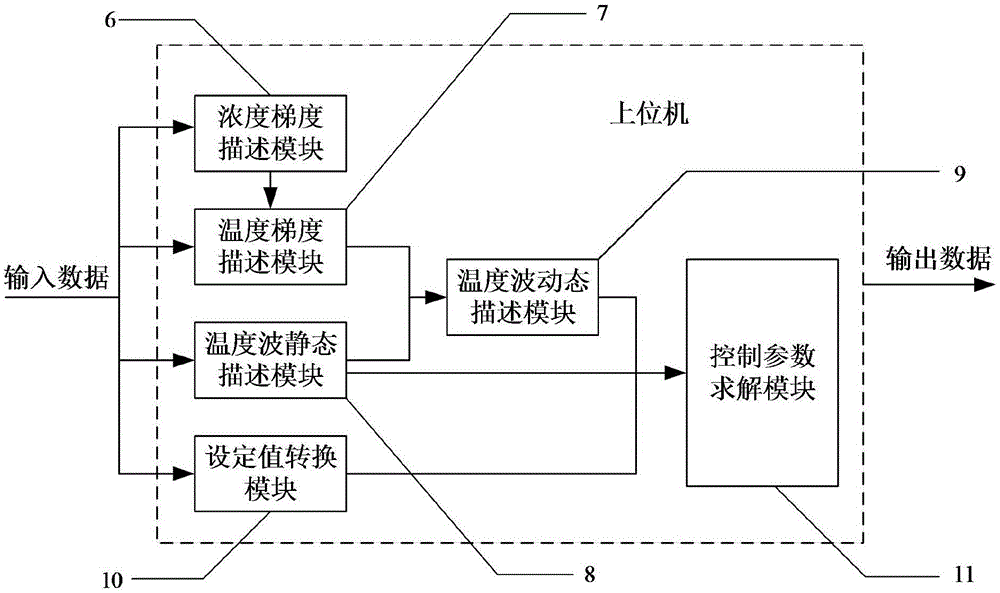

[0101] Such as figure 1 and figure 2 As shown, an internal thermally coupled rectification control device based on temperature wave model predictive control includes an internal thermally coupled rectification tower 1, an intelligent instrument 2, a control station 3, a data storage device 4, and a host computer 5. The intelligent instrument 2 is connected to the internal thermally coupled rectification tower 1 for data collection; the control station 3 is connected to the internal thermally coupled rectification tower 1 for controlling the internal thermally coupled rectification tower 1; The data storage device 4 is connected with the smart meter 2 and the control station 3 for realizing data storage; the host computer 5 is connected with the data storage device 4 and the control station 3 for realizing control For the solution of parameters, the upper computer 5 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com