Device Handling Method

A processing method and device technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of large forward voltage drop of devices, improve forward characteristics, improve roughness, and reduce positive voltage. The effect of the pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

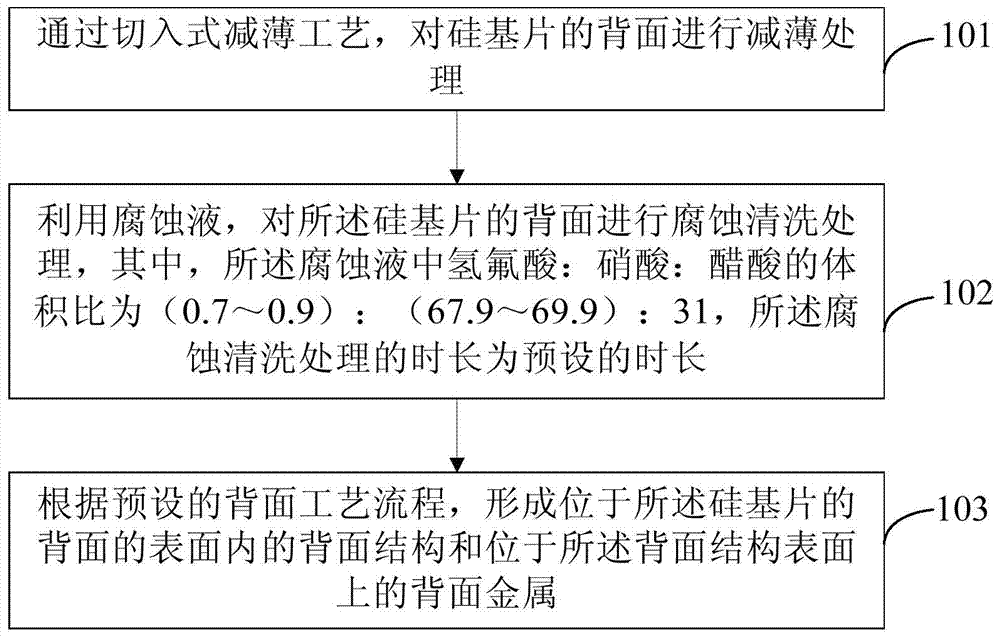

[0012] figure 1 A schematic flow chart of a device processing method provided in Embodiment 1 of the present invention, such as figure 1 As shown, the method includes:

[0013] 101. Thinning the back side of the silicon substrate through a cut-in thinning process.

[0014] Specifically, in practical applications, it is usually necessary to form the front structure of the device before performing the process flow of the back side of the device. Correspondingly, before step 101, the method may further include:

[0015] forming a front structure located in and on the front surface of the silicon substrate according to a preset front process flow;

[0016] A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com