Polarization Converter Based on Multilayer Frequency Selective Surface

A frequency selective surface and converter technology, applied in the microwave field, can solve the problems of complex structure, high loss and high cost of electrically modulated polarization converters, and achieve the advantages of improving polarization and angular stability, enhancing angular stability and avoiding loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

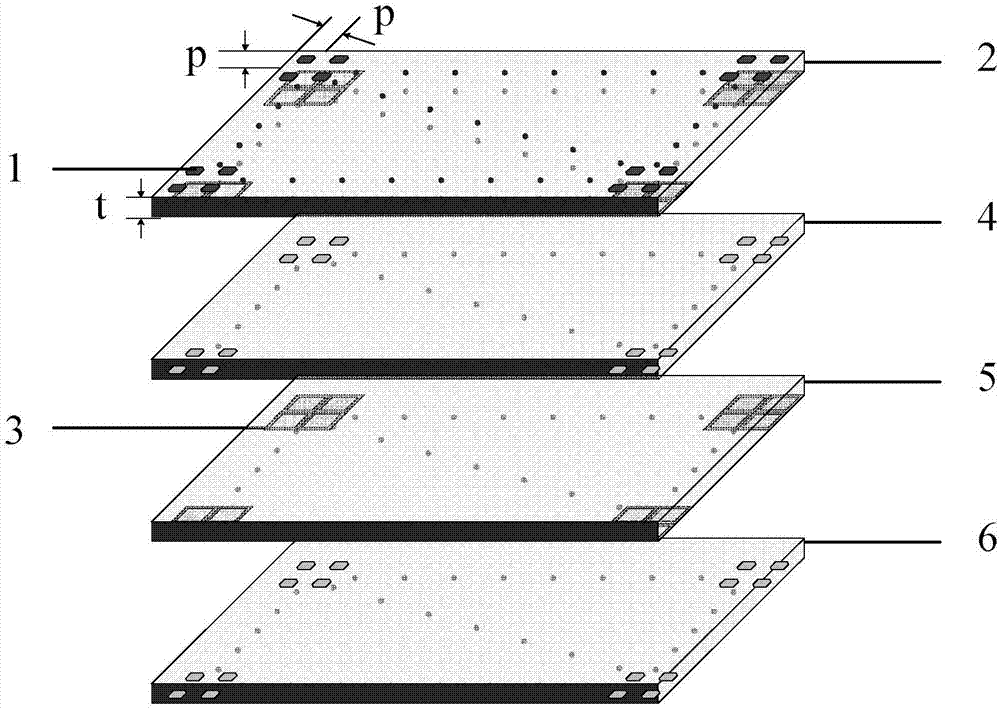

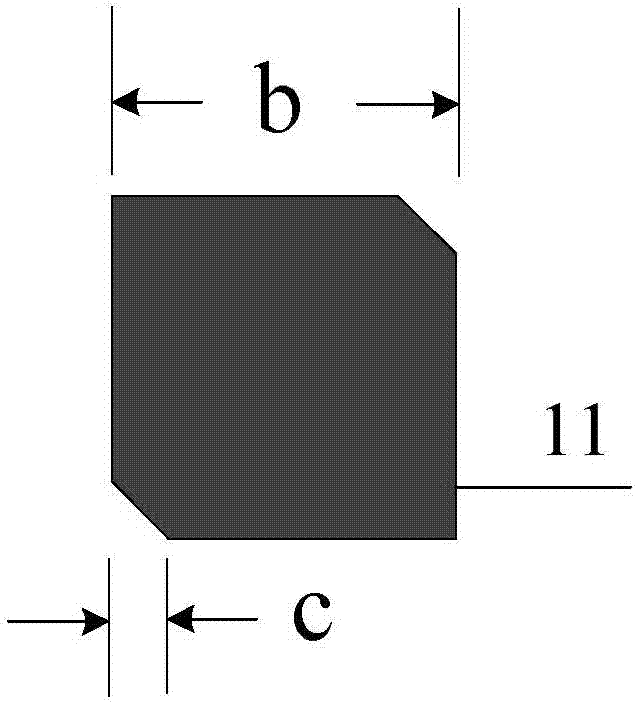

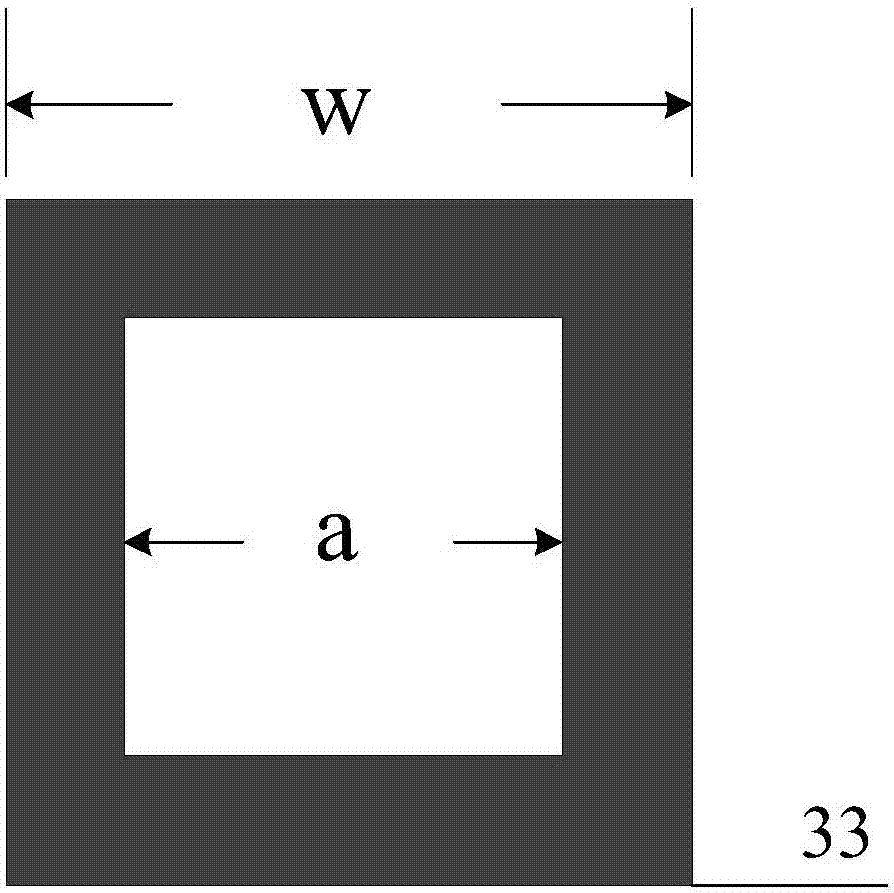

[0024] refer to figure 1 , the first dielectric plate 2, the second dielectric plate 4, the third dielectric plate 5 and the fourth dielectric plate 6 are all made of polytetrafluoroethylene material, and its relative permittivity ε r =2.6±0.05, dielectric loss tanδ=0.015, substrate thickness t=1.5mm; printed on the upper surface of the first dielectric plate 2, the lower surface of the second dielectric plate 4 and the lower surface of the fourth dielectric plate 6 respectively A patch array 1 composed of 8×8 corner-cut square patches 11; the lower surface of the first dielectric plate 2 and the lower surface of the third dielectric plate 5 are printed with 8×8 metal square rings 33 The grid array 3; the first dielectric board 2, the second dielectric board 4, the third dielectric board 5 and the fourth dielectric board 6 are fixed from top to bottom by heat pressing with insulating adhesive material or using media screws, Forming a stacked structure up and down, this multi-...

Embodiment 2

[0028] Embodiment 2 has the same structure as Embodiment 1, only the following parameters are adjusted:

[0029] The four-layer dielectric boards 2, 4, 5 and 6 all adopt Teflon (tm), and its relative permittivity ε r =2.1, dielectric loss tanδ=0.001, substrate thickness t=1mm; number of periodic units M×N=2×2 forming patch array 1 and grid array 3, period p=8mm; square patch 11 side length b =5mm, the side length of the cut corner c=1.5mm; the outer side length w=8mm of the square ring 33, and the inner side length a=6mm.

Embodiment 3

[0031] Embodiment 3 has the same structure as Embodiment 1, only the following parameters are adjusted:

[0032] The four-layer dielectric boards 2, 4, 5 and 6 all adopt Taconic CER-10(tm), and its relative permittivity ε r =10, dielectric loss tanδ=0.035, substrate thickness t=3mm; number of periodic units M×N=128×128 that make up patch array 1 and grid array 3, period p=20mm; square patch 11 side length b =15mm, the side length of the cut corner c=5mm; the outer side length w=20mm of the square ring 33, and the inner side length a=16mm.

[0033] Effect of the present invention is further described below in conjunction with simulation result:

[0034] 1. Simulation content: using Ansys HFSS 13.0, for example Figure 4 The simulation model of the shown embodiment 1 performs full-wave simulation. In the 8.5GHz-11GHz frequency band, a standard gain horn is used as a transmission source, and the emitted linear polarized wave is vertically irradiated on the polarization converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com