All-solid state same-frequency and same-phase output variable-frequency double power source

A technology of co-frequency co-phase, variable frequency power supply, applied in the field of warm forging equipment, can solve problems such as electromagnetic interference, and achieve the effect of improving mold life, improving heating thermal efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

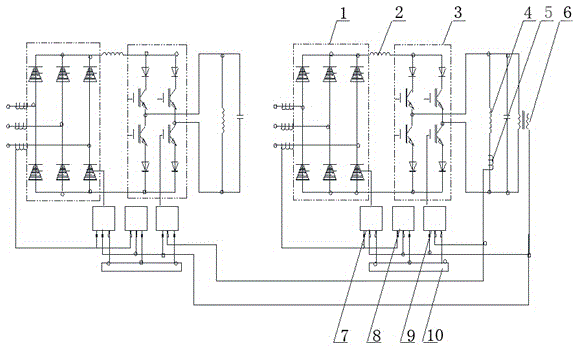

[0017] as attached figure 1 As shown, the all-solid-state dual power supply with the same frequency and phase output frequency conversion, its structure includes two sets of all-solid-state frequency conversion power supplies with the same frequency and phase output A and B, and induction heating furnace induction coil 4, induction furnace frequency conversion current signal transformer 5, induction furnace frequency conversion Voltage signal transformer 6; each set of power supply includes thyristor full-bridge rectification part 1, DC reactor 2, IGBT inverter 3 and rectification circuit trigger 7, protection signal generator 8, inverter circuit drive trigger 9, Auxiliary DC power supply 10, wherein the rectification part 1, DC reactor 2, and IGBT inverter 3 are connected in series, and the power output end of the auxiliary DC power supply 10 is connected to the rectification circuit trigger 7, the protection signal generator 8, and the inverter circuit drive The power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com