Spraying method of deep cone thickener

A deep cone concentrator and coating technology, which is applied in the direction of surface coating liquid devices, coatings, lifting devices, etc., can solve the problems of short service life and high cost, and achieve increased service life, improved concentration efficiency, and underflow concentration. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

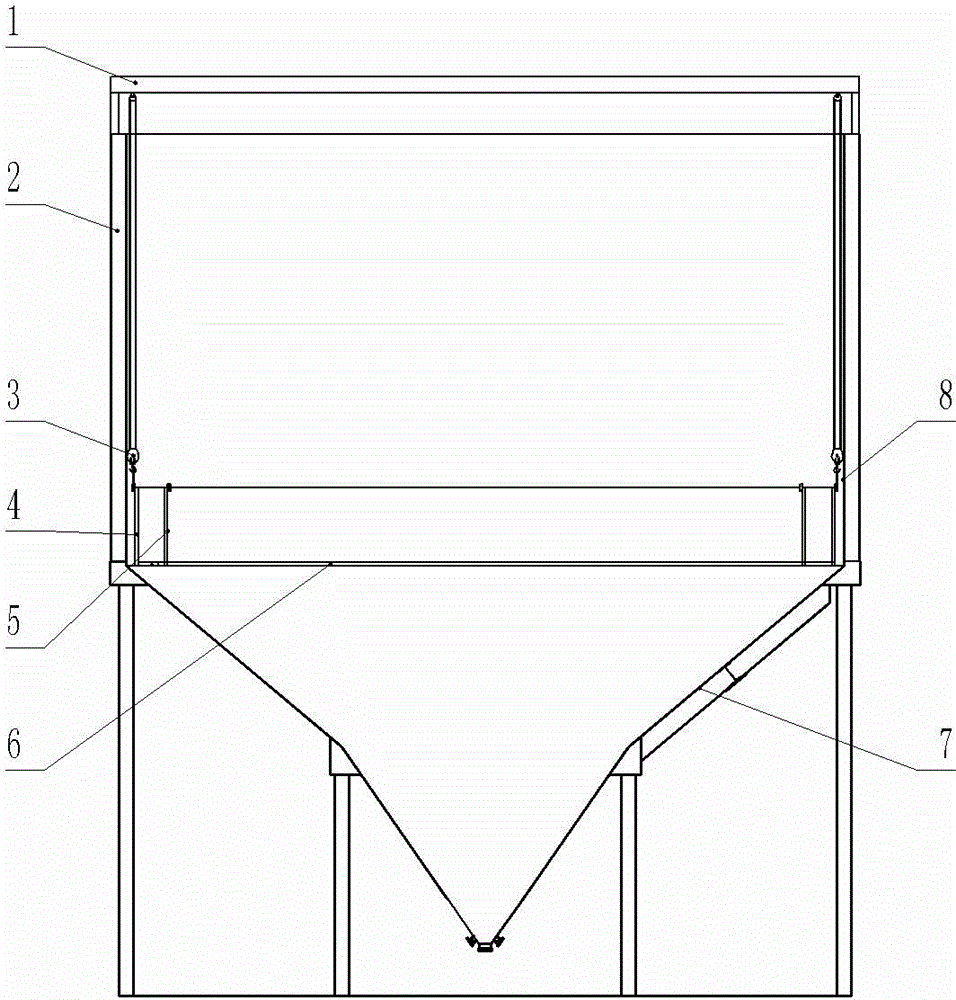

[0019] Such as figure 1 The shown deep cone concentrator includes a cylinder, the cylinder has a cylindrical portion 8 and a cone portion 7 connected to the bottom of the cylindrical portion 8, and the inner wall of the cylindrical portion 8 is provided with a layer of wear-resistant and anti-corrosion polymer with a thickness of 2.5 mm. urea.

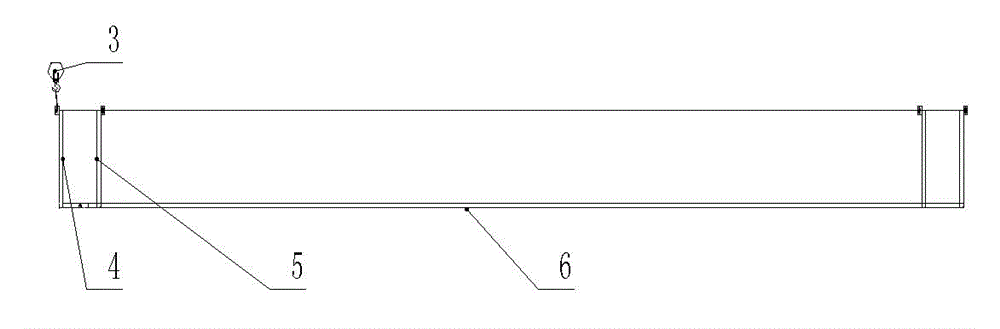

[0020] A method for spraying with a deep cone thickener, using a method such as figure 2 The cylinder body spraying tool shown is for spraying the inner wall of the cylinder part 8. The cylinder body spraying tool includes a bracket 1 erected on the top of the cylinder part 8, and the bracket 1 is movably hoisted with a lifting frame 6 by a sling 3. A circular aisle with an inner fence 5 and a peripheral fence 4 is arranged on the lifting frame 6. A plurality of lifting lugs are welded on the top of the peripheral fence 4 and an iron chain is worn on the first lifting lug, and the iron chain hook is hung on the spreader. 3 on the ho...

Embodiment 2

[0031] Such as figure 1 The shown deep cone concentrator includes a cylinder, the cylinder has a cylindrical portion 8 and a cone portion 7 connected to the bottom of the cylindrical portion 8, and the inner wall of the cylindrical portion 8 is provided with a layer of wear-resistant and anti-corrosion polymer with a thickness of 3.5 mm. urea.

[0032] A method for spraying with a deep cone thickener, using a method such as figure 2 The cylinder body spraying tool shown is for spraying the inner wall of the cylinder part 8. The cylinder body spraying tool includes a bracket 1 erected on the top of the cylinder part 8, and the bracket 1 is movably hoisted with a lifting frame 6 by a sling 3. A circular aisle with an inner fence 5 and a peripheral fence 4 is arranged on the lifting frame 6. A plurality of lifting lugs are welded on the top of the peripheral fence 4 and an iron chain is worn on the first lifting lug, and the iron chain hook is hung on the spreader. 3 on the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com