Preparation method of magnetic powder

A magnetic powder and magnetic material technology, which is applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of material crystal structure damage, etc., and achieve the effect of strong texture, simple steps and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Weigh the coarsely crushed SmCo 5 Put 5g of material (particle size less than 400μm) into a stainless steel ball mill jar, then add 100g of stainless steel balls (20g for 8mm, 80g for 5mm), and 1ml oleic acid and 1ml oleylamine as surfactants, and finally add 100ml n-heptyl alkanes as organic solvents.

[0029] 2. Seal the ball mill tank containing magnetic material, grinding balls, surfactant and organic solvent in a glove box. Put the sealed ball mill jar on the GN-2 type high-energy ball mill, and ball mill for 5 hours at a voltage of 30v (about 150 rpm); then ball mill for 10 hours at a voltage of 40v (about 200 rpm); then Ball milled for 15 hours at a voltage of 50v (about 250 rpm).

[0030] 3. Take out the balls, pour the milled product into a centrifuge tube, wash it with n-heptane for 5 times, and then dry it to obtain the magnetic powder of the present invention.

[0031] product characterization

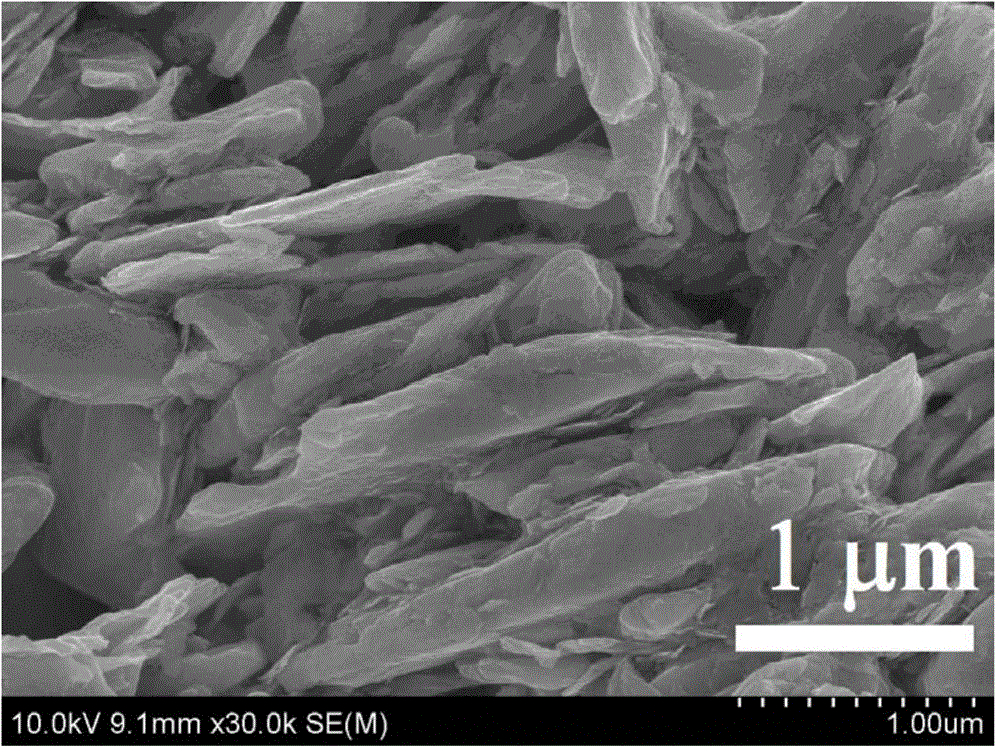

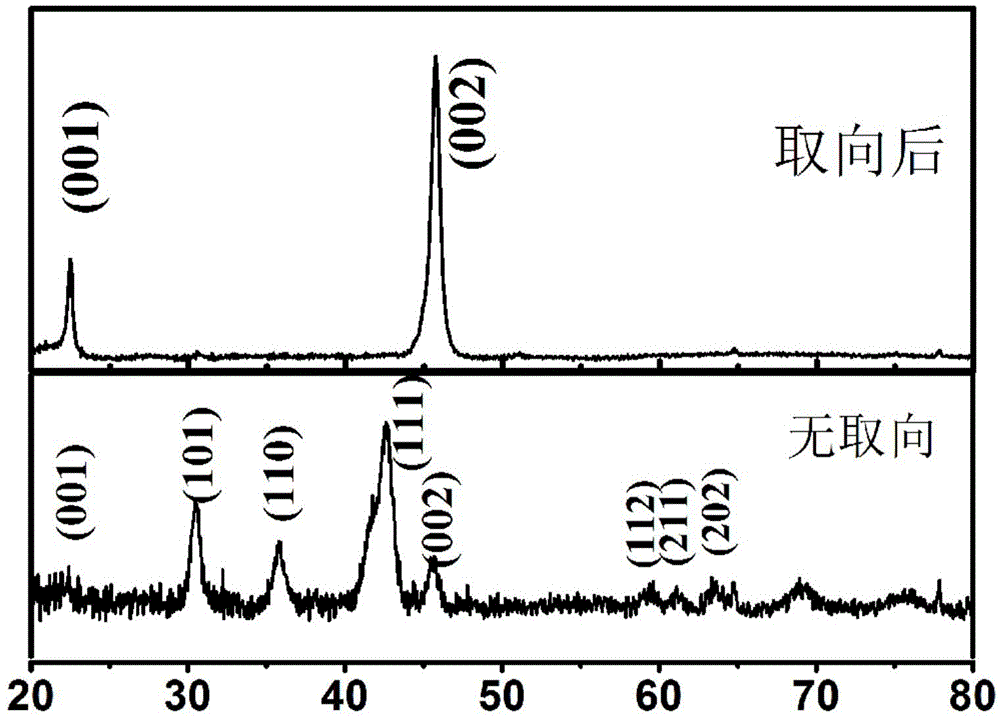

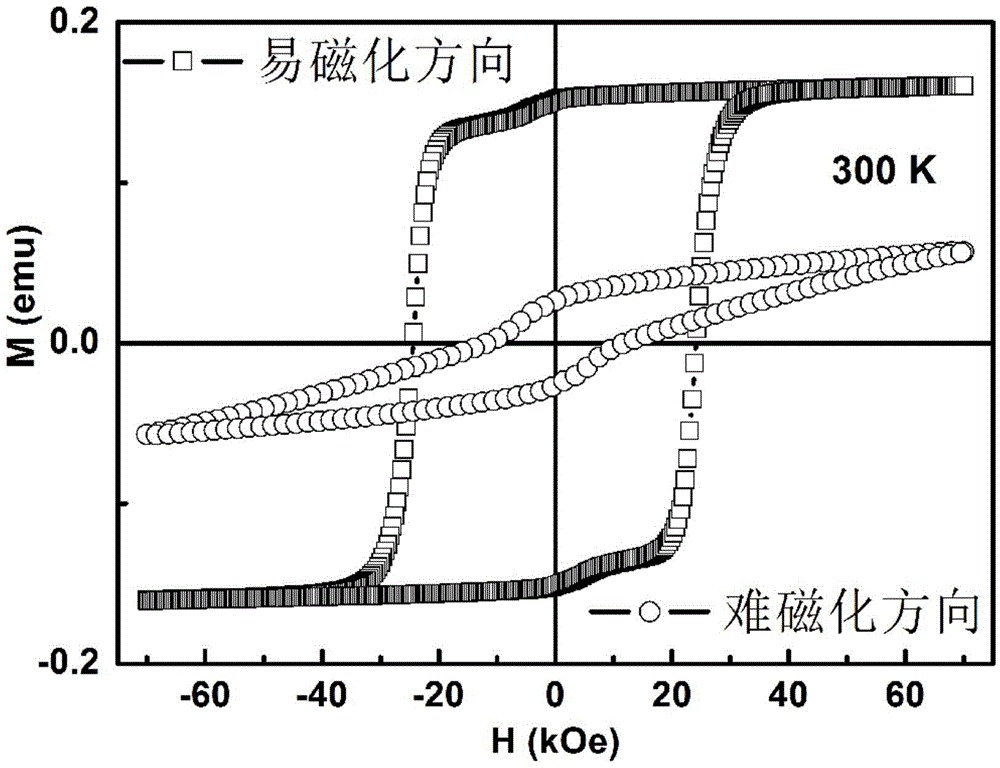

[0032] 1. Put the magnetic powder prepared in this emb...

Embodiment 2

[0045] 1. Weigh the coarsely crushed SmCo 5 5g of material (particle size less than 400μm) was put into a stainless steel ball mill jar, then 100g of stainless steel balls (20g of 8mm, 80g of 5mm) were added, and finally 100ml of n-heptane was added as an organic solvent.

[0046] 2. Seal the ball mill jar with magnetic material, grinding balls and organic solvent in the glove box. Put the sealed ball mill jar on the GN-2 high-energy ball mill, ball mill for 1 hour at a voltage of 30v (about 150 rpm), then ball mill for 2 hours at a voltage of 40v (about 200 rpm), and then Ball milled for 4 hours at a voltage of 50v (about 250 rpm).

[0047] 3. Take out the balls, pour the ball-milled product into a centrifuge tube, rinse with n-heptane for 5 times, and then dry to obtain the magnetic powder of the present invention.

[0048] The measurement results of the magnetic powder prepared in this embodiment are shown in Table 1.

Embodiment 3

[0056] 1. Weigh the coarsely crushed Pr 2 Fe 14 5g of material B (particle size less than 400μm), put it into a stainless steel ball mill tank, then add 100g stainless steel grinding balls (20g for 8mm, 80g for 5mm), and 1ml oleic acid and 1ml oleylamine as surfactants, and finally add 100ml n-heptyl alkanes as organic solvents.

[0057] 2. Seal the ball mill tank containing magnetic material, grinding balls, surfactant and organic solvent in a glove box. Put the sealed ball milling tank on the GN-2 high-energy ball mill, ball mill for 1 hour at 30v (about 150 rpm), 1 hour at 40v (about 200 rpm), and 1 hour at 50v (about 250 rev / min) voltage ball milled for 2 hours, then ball milled for 2 hours under 60v (about 300 rev / min) voltage.

[0058] 3. Take out the balls, pour the ball-milled product into a centrifuge tube, rinse with n-heptane for 5 times, and then dry to obtain the magnetic powder of the present invention.

[0059] The measurement results of the magnetic powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com