Dumping device for truck

A technology of a self-unloading device and a truck, which is applied in the direction of tilting and carrying vehicles, etc., can solve the problems such as the hydraulic system failure is not easy to check, the turning angle of the loading carriage is not easy, and there is oil pollution, etc., and the transmission process can be accurately controlled and compact. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The truck self-unloading device of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

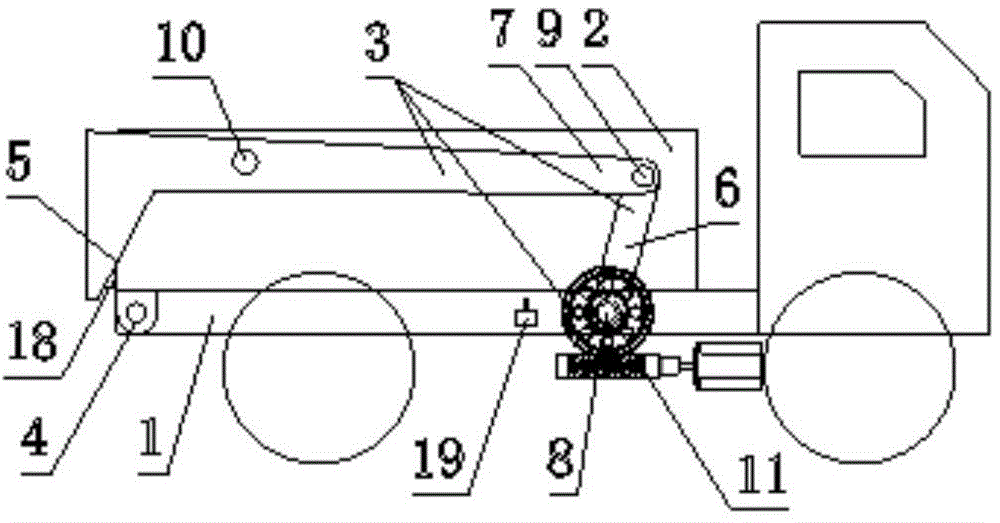

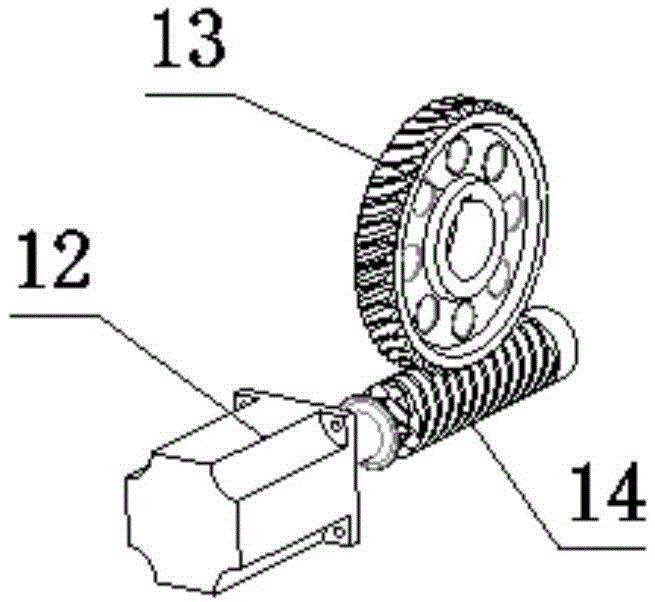

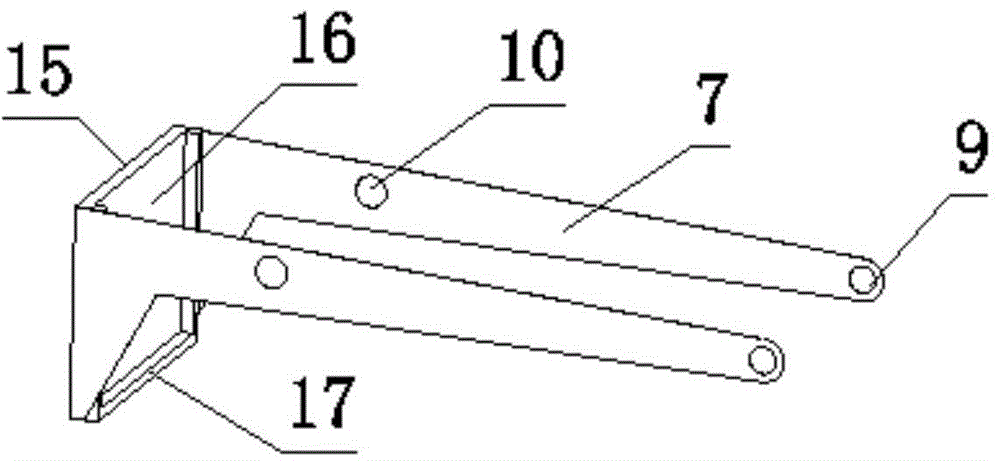

[0022] Such as figure 1 As shown, the truck self-unloading device of the present invention includes a car body 1, a cargo compartment 2 and a lifting mechanism 3, and the rear portion of the cargo compartment 2 is provided with a lifting lug 4, which is hinged with the vehicle body 1 through the lifting lug 4, so that The cargo compartment 2 can be overturned relative to the vehicle body 1 with the center of the lifting lug 4 as the axis. The rear portion of the loading compartment 2 is also provided with a discharge port 5, and the goods are discharged from the discharge port 5 during unloading. The lifting mechanism 3 includes a driving mechanism 11, a rocker 6 and a connecting rod 7. The two ends of the rocker 6 are respectively provided with a first hinge point 8 and a second hinge point 9, and the rocker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com