Quay crane loading and unloading operation remote-control operation system and operation method thereof

A technology of remote control and operating system, which is applied in the direction of transportation and packaging, traveling bridge cranes, load suspension components, etc., and can solve problems such as the inability to form a working environment for operators, affect production safety, and poor on-site operating conditions. Achieve the effects of saving labor expenses, facilitating accurate control, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

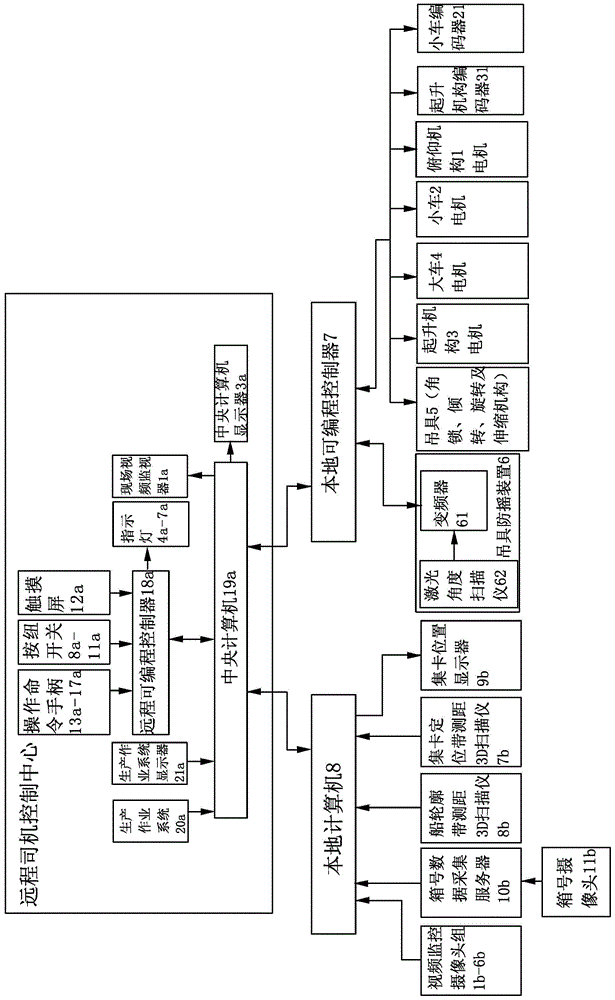

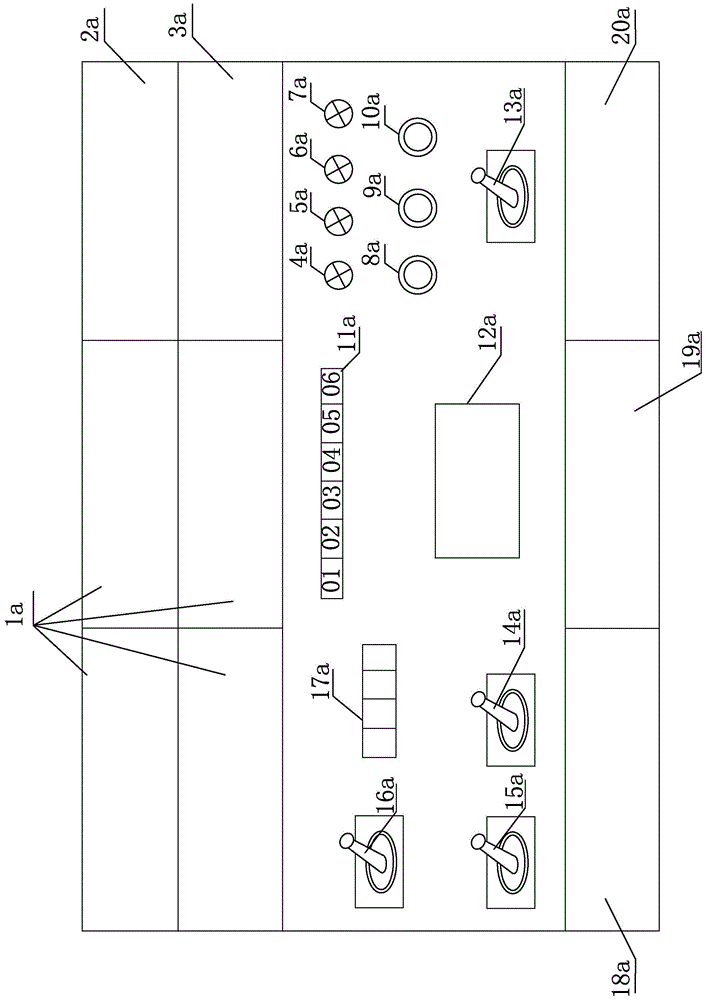

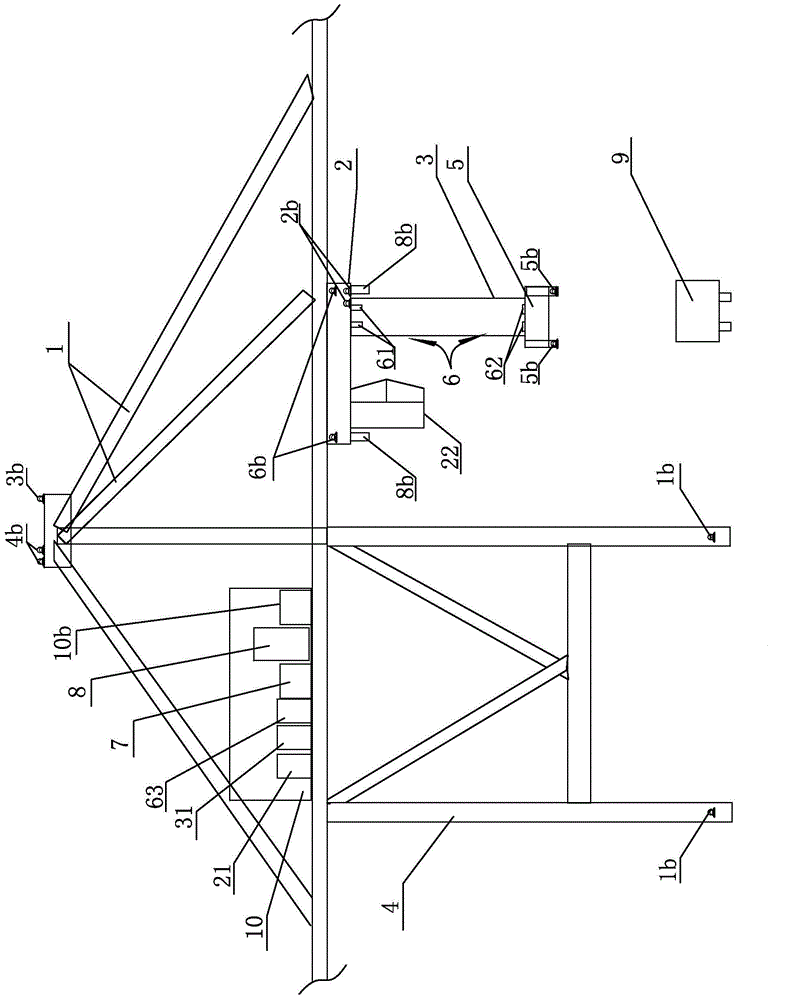

[0059] figure 1 It is a structural block diagram of the remote control operating system for the loading and unloading operation of the quay crane; figure 2 is a structural diagram of the remote driver control center; image 3 It is a schematic diagram of the distribution of on-site video surveillance cameras and ship contour ranging 3D scanners on the quay bridge; Figure 4 It is a schematic diagram of the layout and principle of the positioning device of the collection card. The quay bridge is composed of a pitching mechanism 1, a hoisting mechanism 3, a trolley 2 and a cart 4, such as figure 1 As shown, the automated operating system includes a production operation system 20a that issues loading and unloading instructions, loading and unloading bays and container numbers, a local programmable controller 7 installed on the quay bridge and a hoisting mechanism motor connected to it controlled by it , hoisting mechanism encoder 31, pitching mechanism motor, cart motor, trol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com