A kind of preparation method of decinil

A technology of desiginil and molar ratio, which is applied in the field of preparation of desiginil, can solve the problems of toxicity of synthetic raw materials, high requirements for synthesis conditions, low reaction yield and the like, and achieves high purity, high yield, and operation steps. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

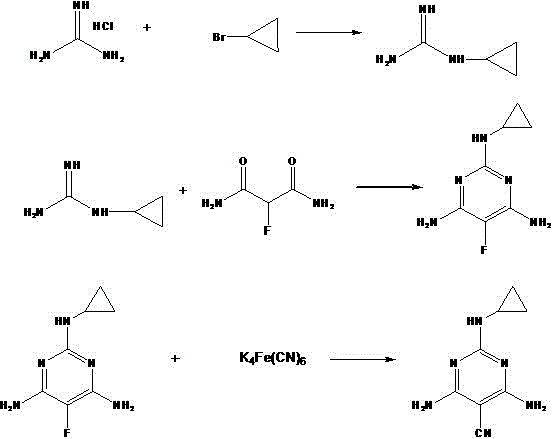

Image

Examples

Embodiment 1

[0026] A preparation method of decinil, the steps are as follows:

[0027] 1) Put 100kg of guanidine hydrochloride and 114kg of bromocyclopropane into 600kg of acetone, stir evenly, add 144kg of potassium carbonate, heat up to 30°C, react for 2.0h, cool down to room temperature, filter, and concentrate the filtrate to dryness under reduced pressure to prepare Obtain intermediate 193.4kg, molar yield 90%;

[0028] 2) Add 374kg of purified water to 193.4kg of the intermediate obtained in step 1), stir evenly, add 90.5kg of 2-fluoromalonamide and 231kg of 20% sulfuric acid, raise the temperature of the system to 30°C, react for 4.0h, and drop to At room temperature, adjust the pH of the system to 7.0 with sodium hydroxide solution, continue to stir, filter, and wash the filter cake with a large amount of water to obtain 112kg of 4,6-diamino-5-fluoro-2-cyclopropylaminopyrimidine, with a yield of 65 %;

[0029] 3) Dissolve 112kg of the prepared 4,6-diamino-5-fluoro-2-cyclopropy...

Embodiment 2

[0032] A preparation method of decinil, the steps are as follows:

[0033] 1) Put 100kg of guanidine hydrochloride and 253kg of bromocyclopropane into 1000kg of acetone, stir evenly, add 289kg of potassium carbonate, heat up to 80°C, react for 4.0h, cool down to room temperature, filter, and concentrate the filtrate to dryness under reduced pressure to prepare Obtain intermediate 195.4kg, molar yield 92%;

[0034] 2) Add 592kg of purified water to 195.4kg of the intermediate obtained in step 1), stir well, add 238.8kg of 2-fluoromalonamide, 487kg of 20% sulfuric acid, raise the temperature of the system to 100°C, react for 5.0h, and drop to At room temperature, adjust the pH of the system to 10.0 with sodium hydroxide solution, continue to stir, filter, and rinse the filter cake with a large amount of water to obtain 118kg of 4,6-diamino-5-fluoro-2-cyclopropylaminopyrimidine, with a molar yield of 67%;

[0035] 3) Dissolve 118kg of the prepared 4,6-diamino-5-fluoro-2-cyclopr...

Embodiment 3

[0038] A preparation method of decinil, the steps are as follows:

[0039] 1) Put 100kg of guanidine hydrochloride and 126.6kg of bromocyclopropane into 800kg of acetone, stir evenly, add 174.6kg of potassium carbonate, heat up to 50°C, react for 3.5h, cool down to room temperature, filter, and concentrate the filtrate to dryness under reduced pressure , obtained intermediate 198.6kg, molar yield 95%;

[0040] 2) Add 428kg of purified water to 198.6kg of the intermediate obtained in step 1), stir well, add 100.8kg of 2-fluoromalonamide, 305kg of 20% sulfuric acid, raise the temperature of the system to 80°C, and react for 4.0-5.0h, Cool down to room temperature, adjust the pH of the system to 7.5 with sodium hydroxide solution, continue to stir, filter, and rinse the filter cake with a large amount of water to obtain 123.9 kg of 4,6-diamino-5-fluoro-2-cyclopropylaminopyrimidine, The molar yield is 68%;

[0041] 3) Dissolve 123.9kg of the prepared 4,6-diamino-5-fluoro-2-cyclo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com