Waste rubber cracking kettle

A cracking kettle and waste rubber technology, applied in the direction of fibrous fillers, etc., can solve the problems of heavy pollution and inability to carry out cracking reactions continuously, and achieve the effect of ensuring purity and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

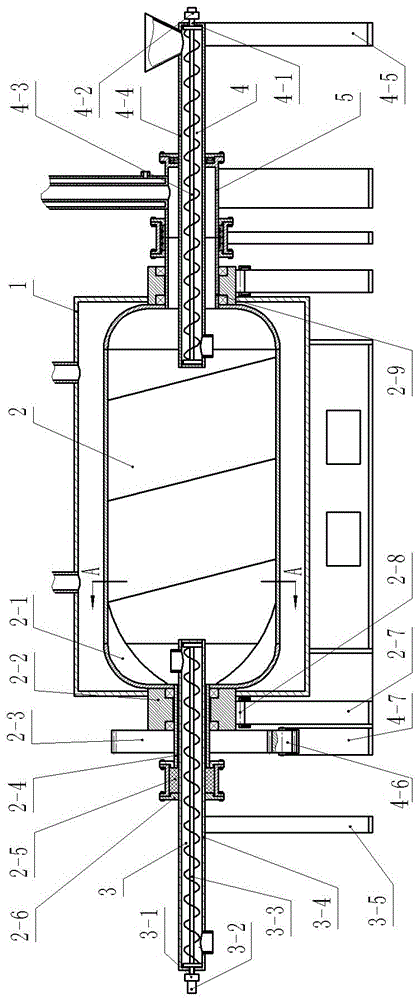

[0016] Below in conjunction with accompanying drawing example the present invention is described in further detail:

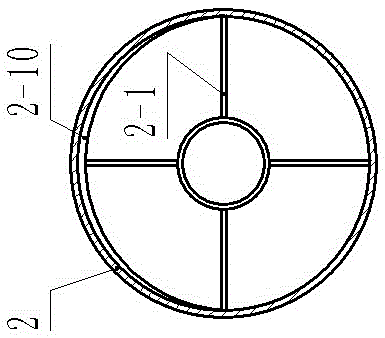

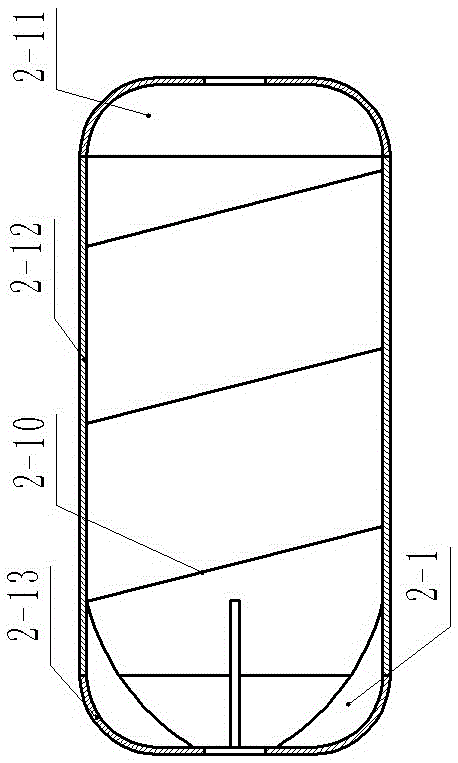

[0017] Such as figure 1 , figure 2 and image 3 The shown waste rubber cracking kettle includes a kettle body 2 driven by a rotary drive device. The kettle body 2 is composed of a cylinder body 2-12 and heads welded at both ends of the cylinder body 2-12. Head 2-11 at the material end, head 2-13 at the discharge end; a discharge hollow shaft 2-4 is welded at the center of the head 2-13 at the discharge end, and a hollow shaft 2-4 is welded at the center of the head 2-11 at the feed end There is a feeding hollow shaft 2-9; a screw pusher plate 2-10 for pushing carbon black from the feeding end to the discharging end is welded on the inner wall of the kettle body 2, and the discharging end cap on the discharging end side is 2-13 The inner wall is radially welded with four arc-shaped deflectors 2-1 to ensure that when the kettle body 2 rotates, the carbon blac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com