Hot-blast stove combustion control method

A control method and hot blast stove technology, which is applied in the field of blast furnace smelting, can solve problems such as large amount of calculation and difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

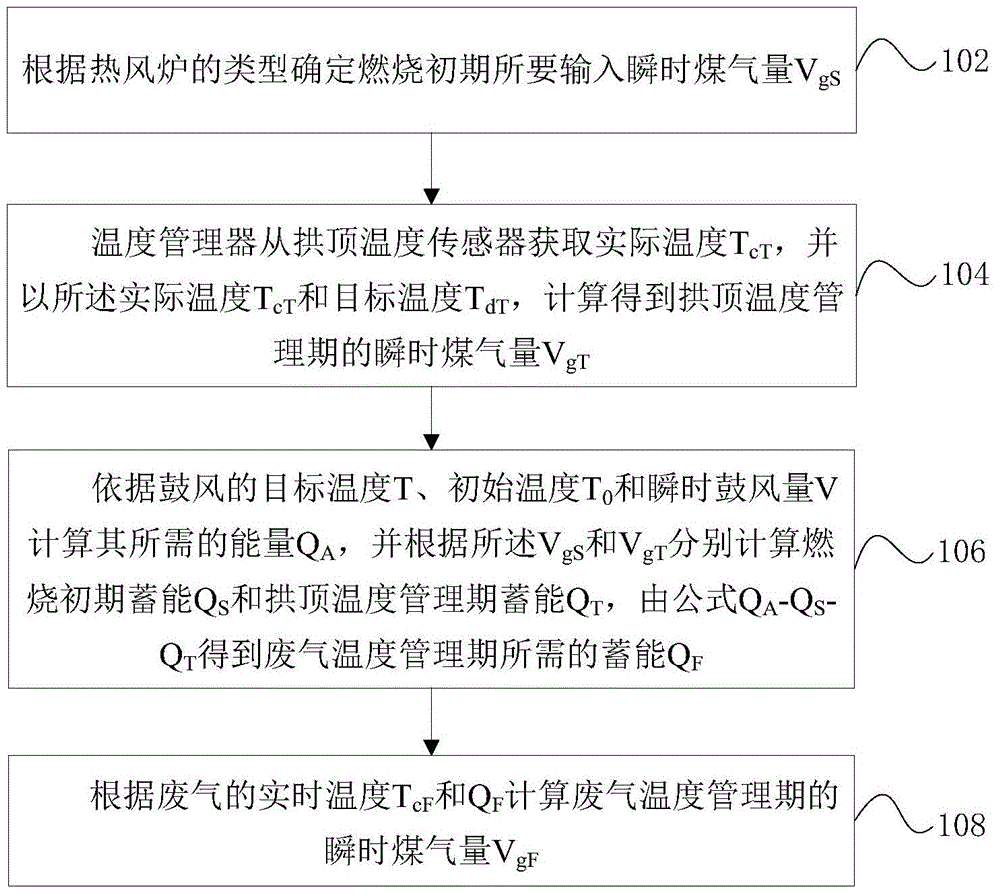

[0019] like figure 1 Shown is a flow chart of a hot blast stove combustion control method provided by an embodiment of the present invention, which consists of figure 1 It can be seen that in the embodiment of a hot blast stove combustion control method provided by the present invention, the hot blast stove combustion control includes the initial combustion period, the vault temperature management period and the exhaust gas temperature management period. The method includes:

[0020] In step 102, the instantaneous gas volume V to be input at the initial stage of combustion is determined according to the type of hot blast stove gS .

[0021] Among them, the instantaneous gas volume V input at the initial stage of combustion gS , which is usually determined when the hot blast stove is selected, and the maximum amount of gas that can be introduced by the gas channel will be taken.

[0022] In step 104, the temperature manager obtains the actual temperature T from the vault tem...

Embodiment 2

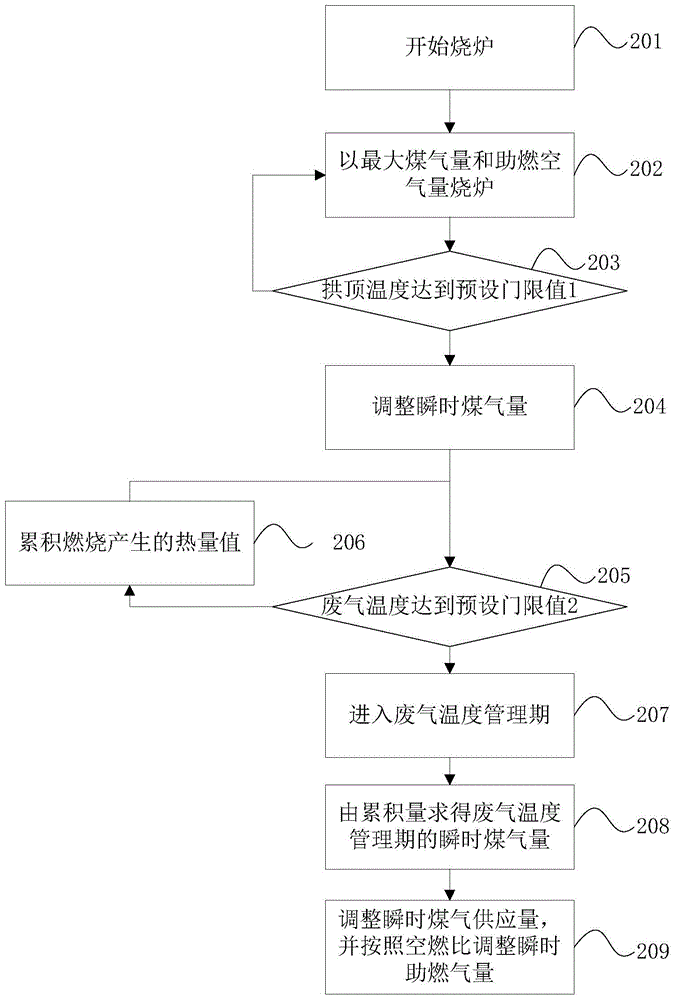

[0058] This embodiment is the application of Embodiment 1 in the specific hot blast stove firing environment, such as figure 2 Shown, specifically include the following steps:

[0059] In step 201, start firing the furnace.

[0060] The furnace specifically includes the initial stage of combustion, the vault temperature management period and the waste gas temperature management period, as described in the first embodiment.

[0061] In step 202, burn the furnace with the maximum amount of gas and combustion air.

[0062] After entering the initial stage of combustion, according to the type of the hot blast stove, the maximum gas volume V that satisfies the process setting is adopted gSmax and the maximum combustion air volume V oSmax , to carry out the furnace process. where V gS and V oS Satisfy the air-fuel ratio k.

[0063] In step 203, it is judged whether the temperature of the dome reaches the preset threshold value 1, which is the reference temperature for judgin...

Embodiment 3

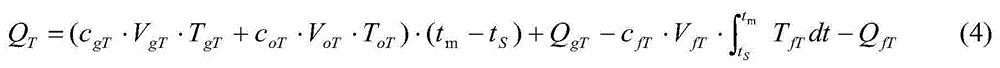

[0075] This embodiment is a specific derivation process given by formula (2), and will start from the algorithm principle supporting the present invention, and illustrate the feasibility and effectiveness of the method of the present invention.

[0076] According to the principle of heat exchange, the energy Q A When it is in the air supply state (the hot blast stove system includes: the combustion state, the stuffy furnace state and the air supply state), the physical heat difference between the cold air blown in by the blower and the hot air blown out after being heated by the hot blast stove, each of the present invention The coal gas and supporting gas mentioned in the embodiments are for heating the hot blast stove, so that the cold wind blown by the blower can complete the heating when passing through the hot blast stove. The physical heat difference is specifically expressed as:

[0077] Q A = ∫ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com