Tailings pond dam body free draining device

An artesian drainage and tailings pond technology, applied in soil drainage, construction, applications, etc., can solve problems such as difficulty in draining water from wells, needing power for drainage, and easy blockage of seepage holes, so as to solve the problems of scaling and easy blocking, precipitation problems, etc. The effect of increased range and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the embodiments.

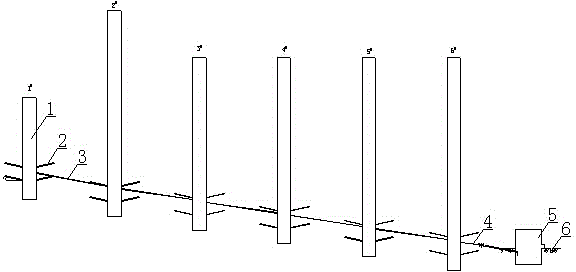

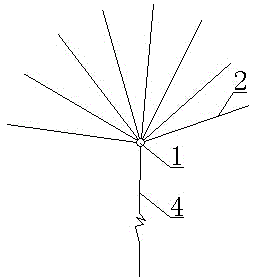

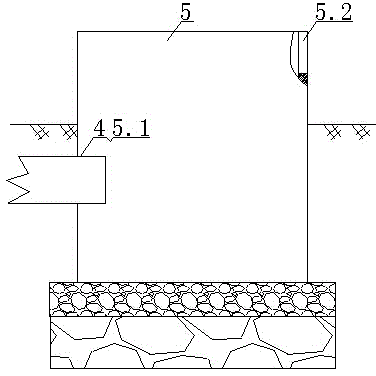

[0017] Depend on Figures 1 to 4 It can be seen that the self-flowing drainage device of the dam body of the tailings pond includes a vertical shaft 1, six vertical shafts are arranged along the stepped dam surface of the dam body, and a water filter pipe 2 with seepage holes is arranged around the vertical shafts, and the distance between two adjacent vertical shafts is 60m. The difference in elevation at the bottom of the shafts is 1m. The bottoms of the two shafts are connected by an aqueduct 3 with a slope of 1 / 60. A drain pipe 4 is installed under the end shaft to connect with the overflow pool 5. The overflow pool is provided with an overflow port 5.2 to connect with the open drainage ditch 6.

[0018] Depend on figure 1 It can be seen that the vertical shaft 1 is made of concrete and has a cylindrical shape, and the bottom of the well is filled with concrete to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com