Construction method for composite insulation mortar

A technology of composite thermal insulation mortar and construction method, which is applied in thermal insulation, climate change adaptation, building components, etc., and can solve the problems of poor energy-saving effect, flammability, and hindering application of inorganic thermal insulation systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

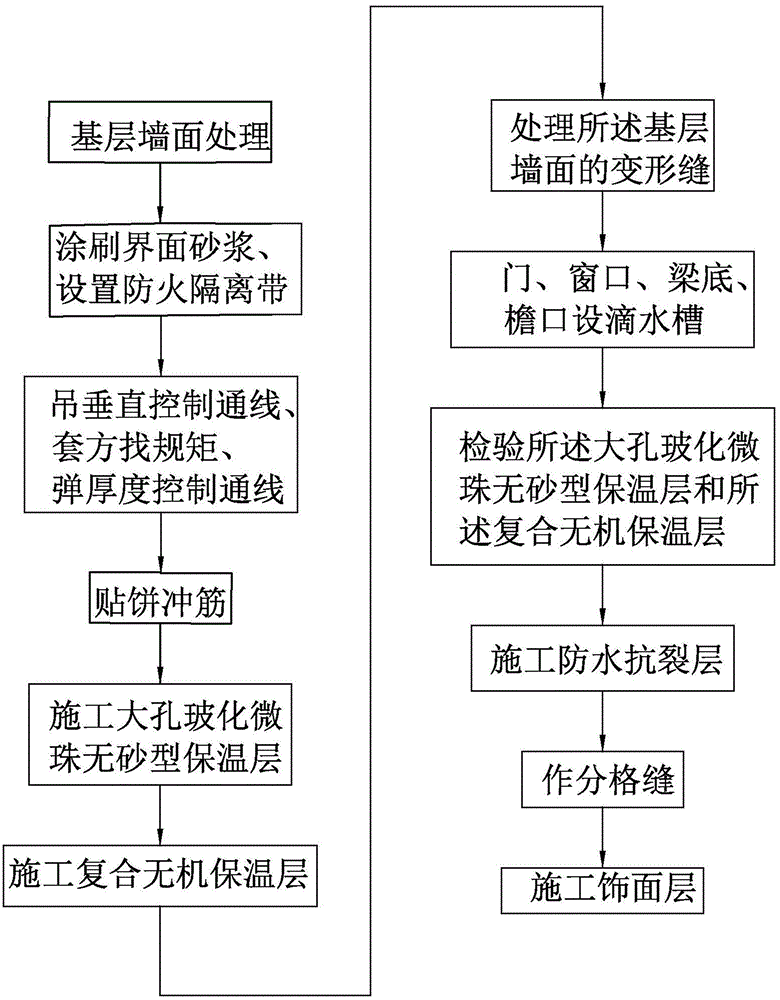

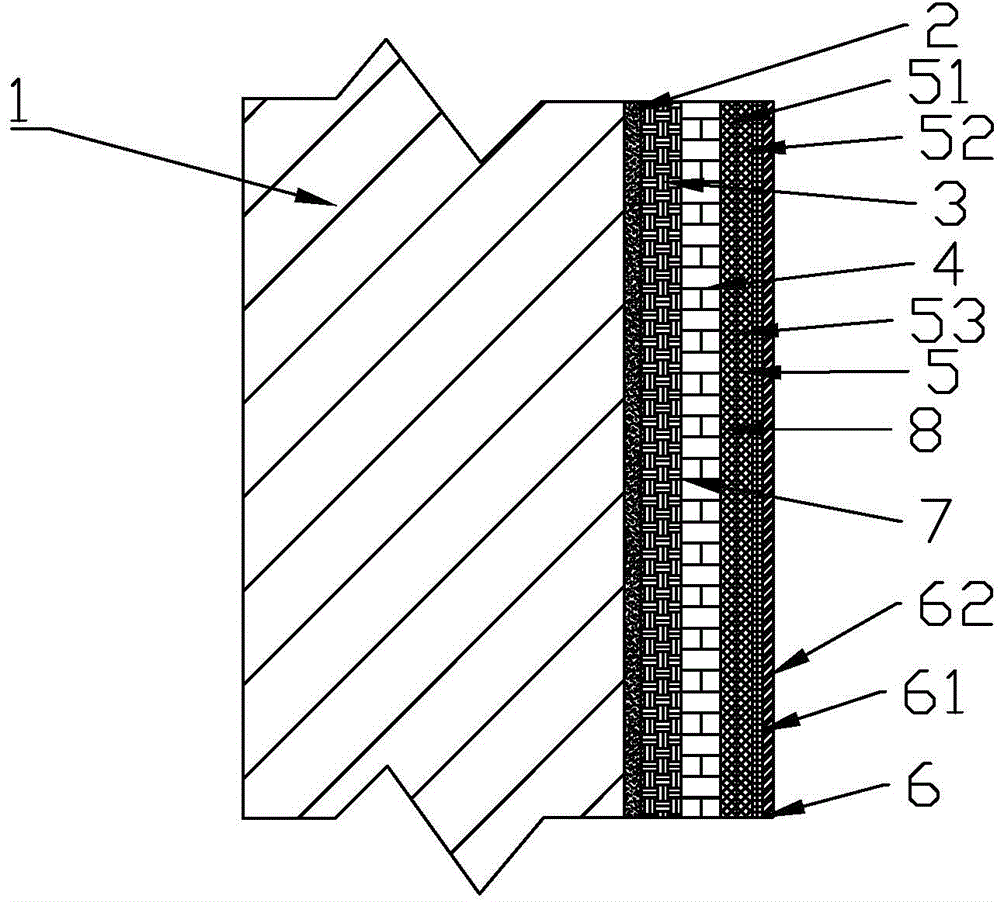

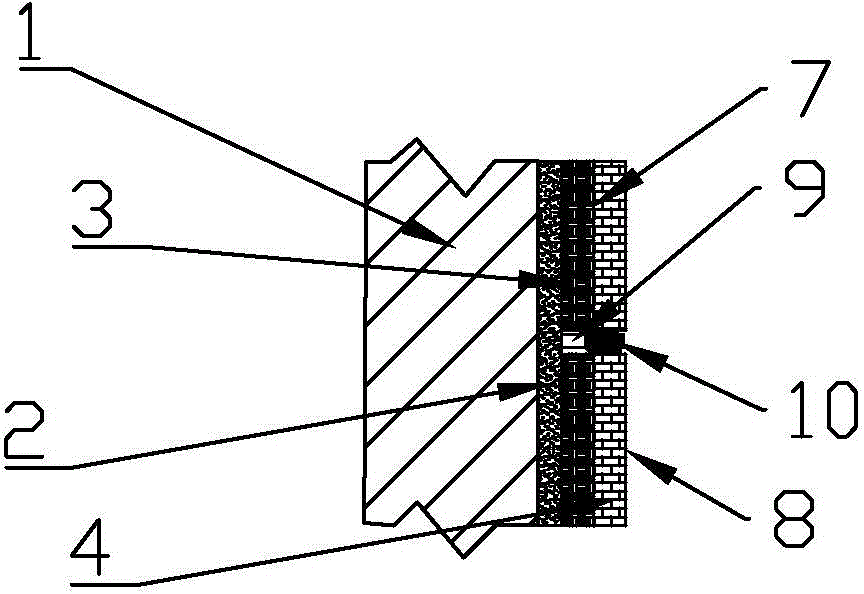

[0036] Such as Figure 1 to Figure 4 As shown, the process of a composite thermal insulation mortar construction method is as follows: 1 treatment of the base wall surface → brushing the interface mortar 2, setting the fire isolation belt → hanging vertical control line, finding rules for the sleeve, elastic thickness control line → pasting cake Punching bars → constructing large-pore vitrified microbead sand-free insulation layer 3 → constructing composite inorganic insulation layer 4 → treating deformation joints on the base wall 1 → setting drip grooves for doors, windows, beam bottoms, and cornices → inspecting large-pore vitrified microbeads Pearl-free sand-type insulation layer 3 and composite inorganic insulation layer 4 → construction of waterproof and anti-cracking layer 5 → making grid joints → construction of facing layer 6.

[0037] (1) Treatment of base wall 1: first, clean the base wall 1, remove loose and weathered parts, and remove protrusions larger than 10 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com