Assembled mining system for deep sea mineral resources

A mineral resource, assembled technology, applied in the mining of minerals, special mining, earth-moving drilling, etc., can solve the problems of high operation requirements, sensitive to offshore wind and wave weather, high manufacturing costs and maintenance costs, and achieves a simplified structure and reduced costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

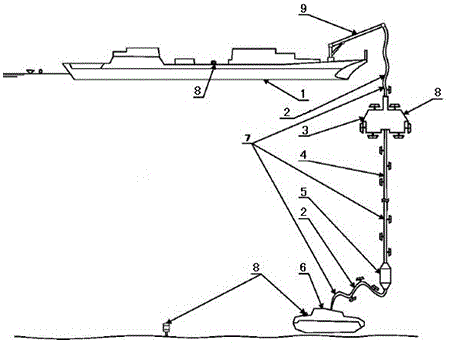

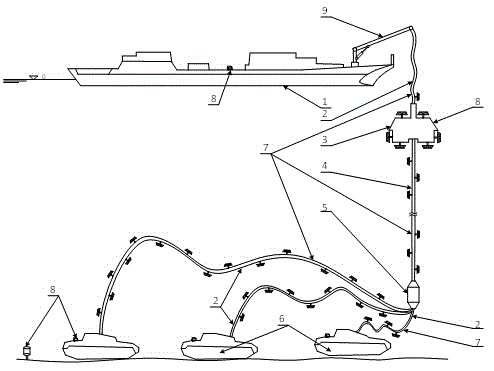

[0037] see figure 2 , when collecting polymetallic sulfide minerals on the seabed, this system mainly includes a mining ship 1, an underwater nuclear power plant 3, an intermediate warehouse 5, a mining machine 6, an ore lifting subsystem 7, an integrated navigation system 8, deployment and lifting The sinking compensation system 9, the crane ship 10, the pipe laying ship 11, the mining ship 1 is connected with the laying and heave compensation system 9, and the ore lifting subsystem 7 is composed of the hose section 2 and the vertical pipe section 4, and the laying and lifting The sinking compensation system 9 is connected to the underwater nuclear power plant 3 through the hose section 2, the underwater nuclear power plant 3 is connected to the intermediate warehouse 5 through the vertical pipe section 4, and the intermediate warehouse 5 is respectively connected to the three mining machines through the hose section 2 6 are connected to ensure that the three-degree-of-freed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com