Method for improving safety of high-capacity lithium ion power battery

A power battery and lithium-ion technology, applied in the field of improving the safety of large-capacity lithium-ion power batteries, can solve problems such as limiting the scope of use, not meeting the safety test standards for power lithium-ion batteries, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings:

[0017] 1. The positive electrode, negative electrode, diaphragm formula and related parameters of the mixed polymer colloidal lithium ion power battery of the present invention:

[0018] 1. Positive electrode formula: lithium iron phosphate (lithium manganese oxide or ternary material), SP, phosphorus flake graphite, LBG1, DBP (plasticizer), solvent is acetone;

[0019] Solid mixture (lithium iron phosphate): acetone=38~40:62~60;

[0020] Solid mixture (lithium manganate or ternary material): acetone=60~63:40~37;

[0021] 2. Negative electrode formula: artificial graphite, SP, LBG1, DBP (plasticizer), solvent is acetone;

[0022] Solid mixture: acetone=44~46:56~54;

[0023] 3. Diaphragm treatment formula: 2801 (adhesive), DBP (plasticizer), ethyl acetate, acetone.

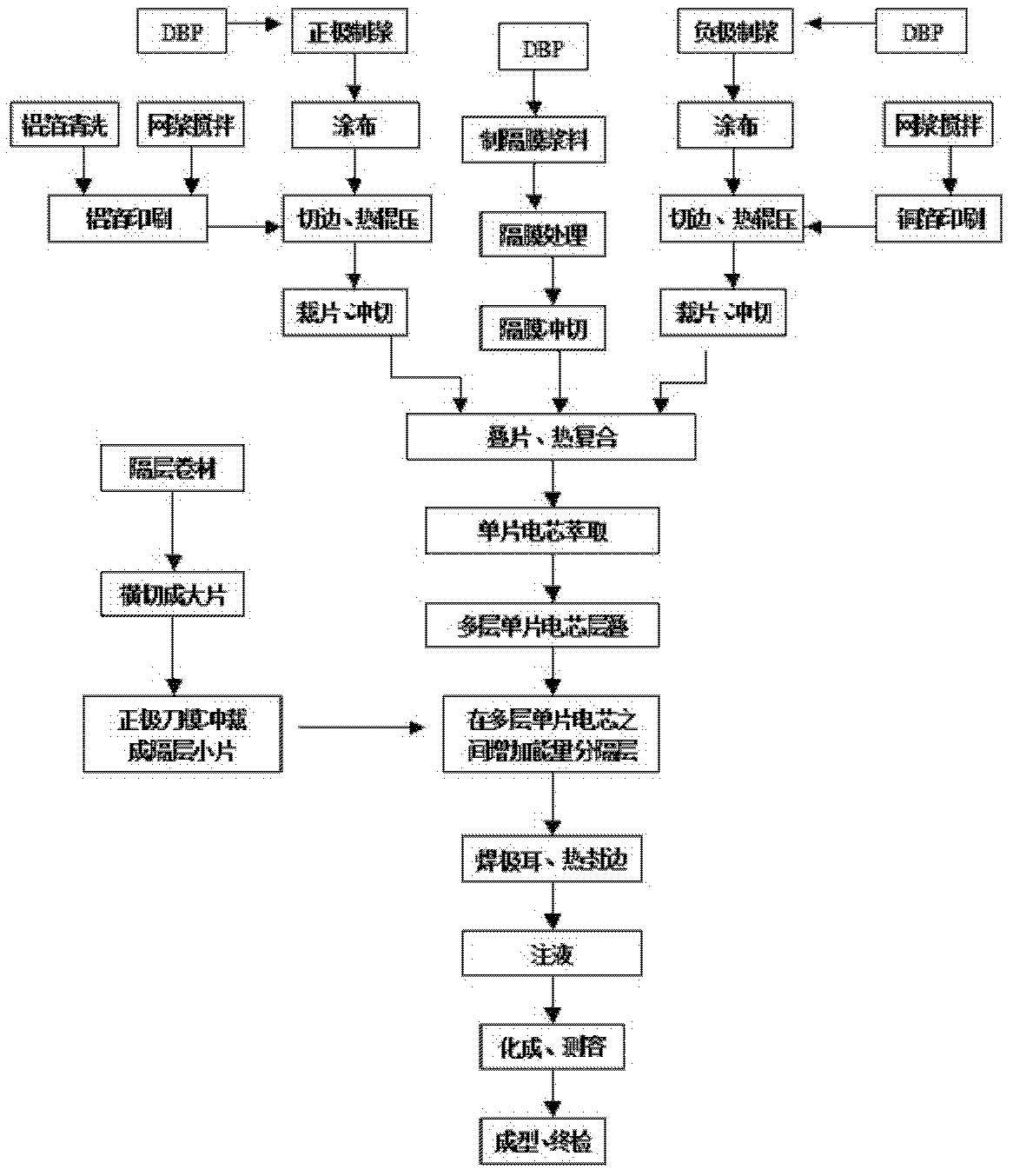

[0024] 2. The production process of mixed polymer colloidal lithium-ion power battery is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com