Hypergravity oil-water separation device

An oil-water separation device and super-gravity technology, which are applied in the separation of sediments by centrifugal force, liquid separation, separation methods, etc., can solve the problems of long oil-water separation time, incomplete oil-water separation, and difficult management, and improve the oil-water separation effect. , The effect of oil-water separation is good, and it is easy to popularize and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

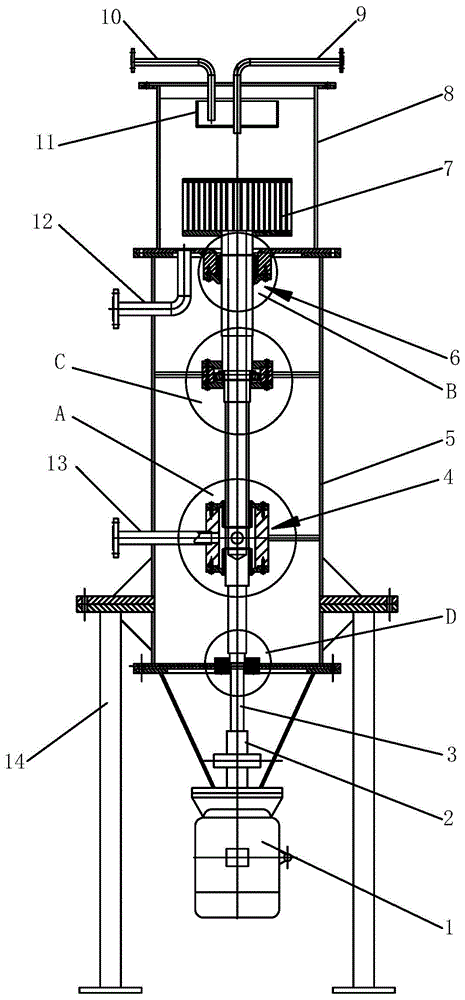

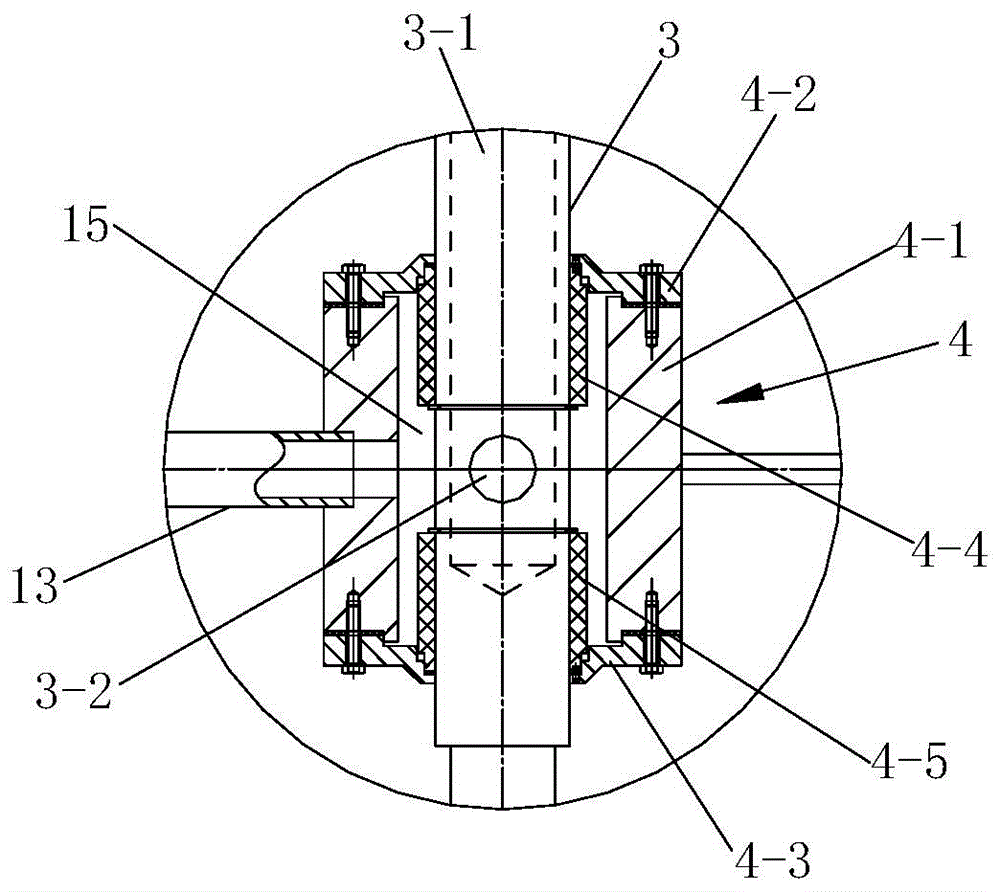

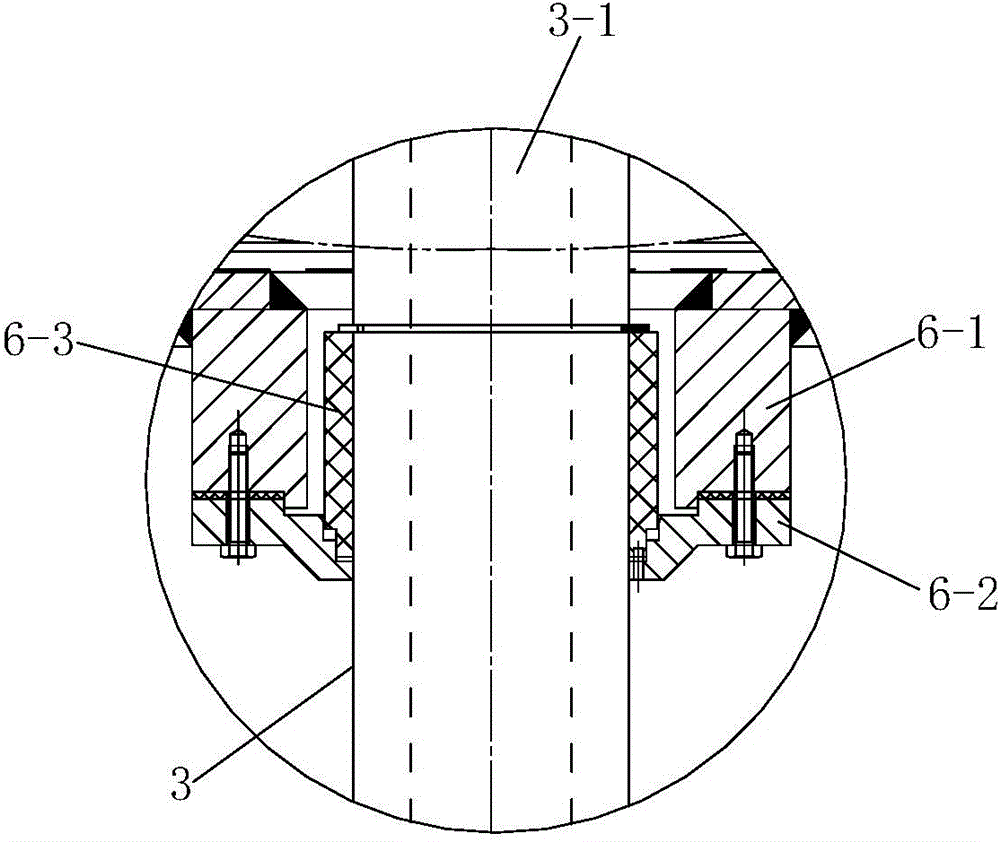

[0044] Such as figure 1 A supergravity oil-water separation device shown includes a frame 5 and a cylinder 8 arranged on the frame 5, and the cylinder 8 is provided with a vortex channel for centrifugally separating the oil-water mixture Separation disc 7, the vortex channel separation disc 7 is provided with a vortex channel for guiding the flow of the oil-water mixture, and the frame 5 is provided with a vortex channel for driving the vortex channel separation disc 7 around the vortex The power mechanism that the vertical central axis of the flow channel separating disc 7 rotates. A leg 14 for supporting it is arranged below the frame 5 .

[0045]In this embodiment, the high-gravity oil-water separation device adopts the vortex channel separation disc 7, and the driving force is provided by the power mechanism to drive the vortex channel separation disc 7 to rotate around its vertical central axis, so that the vortex flow The oil-water mixture in the channel separation dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com