Online cleaning device for lower pressing roll of glass pressing machine

A cleaning device and a technology for a calender, which are applied in the directions of cleaning methods using liquids, cleaning flexible articles, cleaning methods and utensils, etc., and can solve the problems of inability to clean, low cleaning efficiency, and long cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

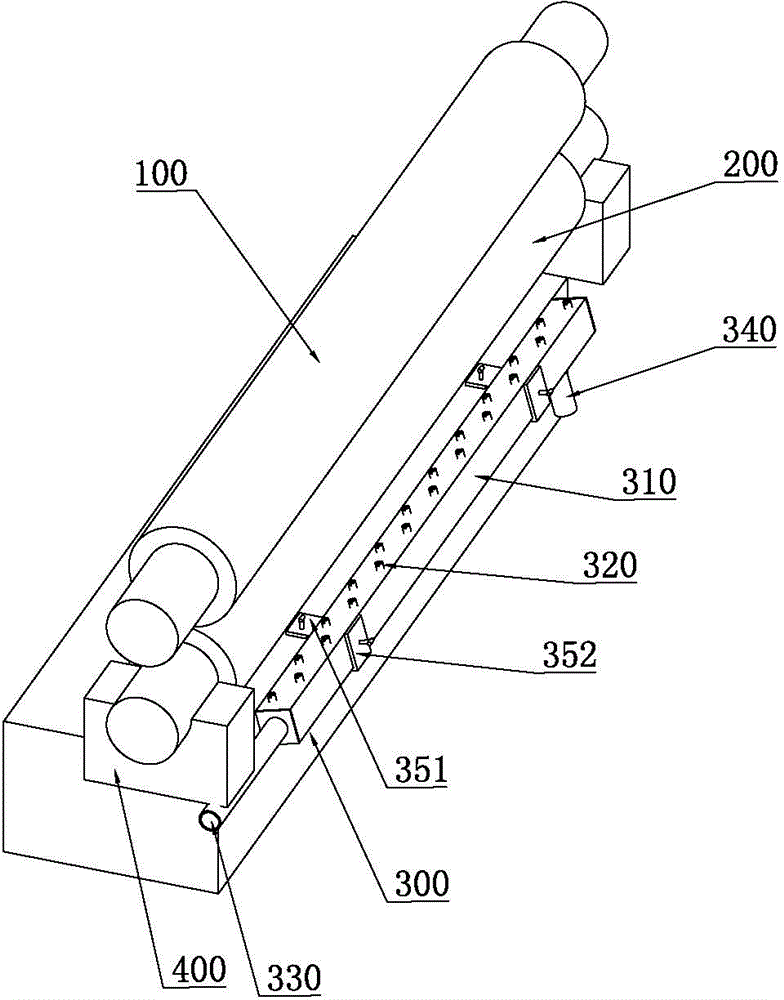

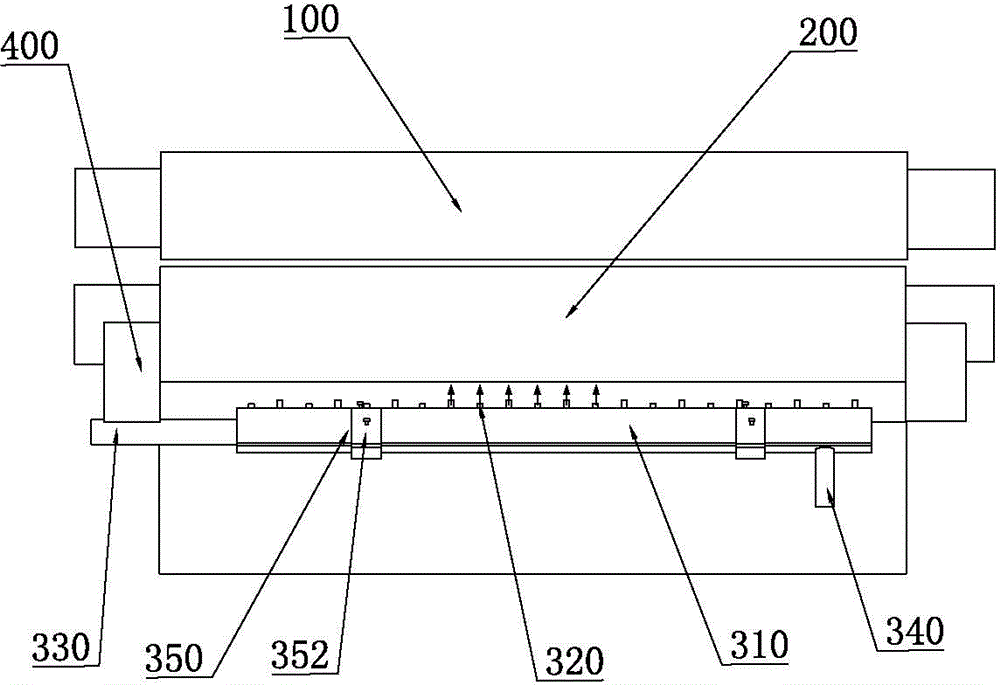

[0040] For a specific implementation of the online cleaning device for the calendering lower roll of a glass calender of the present application, see figure 1 and figure 2 As shown, the online cleaning device 300 is arranged on the calender frame 400 below the calender roll 200. The improvement of the present application is that its structure includes a nozzle 310, and the nozzle 310 is provided with more than two groups of Nozzle groups, each group of nozzle groups is provided with several nozzles 320, the nozzles 320 between adjacent nozzle groups are arranged in a staggered manner in the direction of the center line of the lower calender roll 200, and the liquid surface ejected by each group of nozzle groups is in the vertical direction. On the plane, the nozzle 310 is provided with a liquid inlet 330, and the cleaning liquid with a certain pressure is transported into the nozzle 310 through the liquid inlet 330, and then sprayed out by the two or more nozzle groups to for...

Embodiment 2

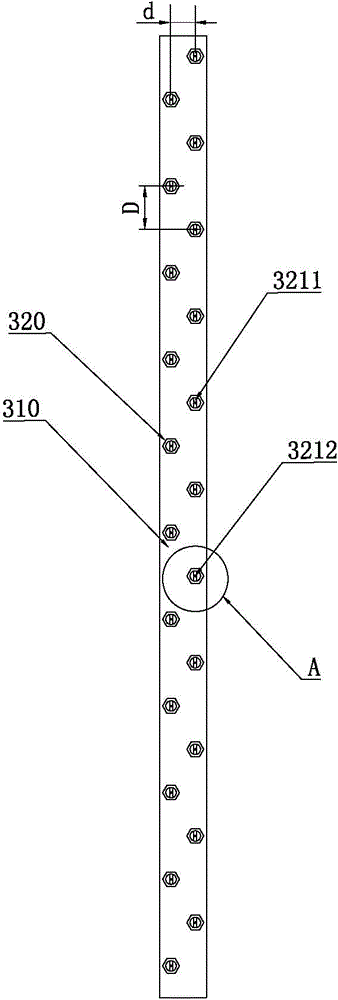

[0044] The second specific embodiment of the online cleaning device for the lower rolling roll of a glass calender according to the present application. The main technical solution of this embodiment is the same as that of Embodiment 1. The features not explained in this embodiment are adopted in Embodiment 1. explanation and will not be repeated here. refer to Figure 3 to Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the spray head 320 includes a nozzle 321, and the nozzle 321 is provided with a V-shaped nozzle groove 3211, and the V-shaped nozzle groove 3211 is provided with a spray hole 3212. The spray head 320 also includes a nut base 322, and the spray head 320 is fixed to the installation hole of the nozzle pipe 310 through the nut base 322. hole (not shown in the figure), the nut base 322 is provided with a liquid outlet hole (not shown in the figure), the liquid outlet hole and the spray hole 3212 are both connected to the nozzle ...

Embodiment 3

[0049] The third specific embodiment of the online cleaning device for the lower roll of a glass calender in the present application, the main technical solution of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment are adopted in Embodiment 1 explanation and will not be repeated here. The difference between this embodiment and Embodiment 1 is that there are different height differences between the liquid surfaces of more than two rows formed by the spraying of the two or more nozzle groups. Different water surface height differences between different liquid levels can be realized by adjusting the pressure of the cleaning liquid that is introduced, or can be realized by the height of the nozzle 320. The cleaning liquid level with height difference is suitable for the online cleaning device 300. From directly below the center line of the lower calender roll 200 to within the boundary area covered by the horizontal plane passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com