Multifunctional cup and pot welding machine

A multi-functional, welding machine technology, applied in the direction of welding equipment, welding rod characteristics, welding equipment, etc., can solve the problems of mechanical welding of stainless steel cups, such as difficulty, time-consuming, and easy to produce defective products, so as to reduce production processes, fast welding speed, Good quality welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

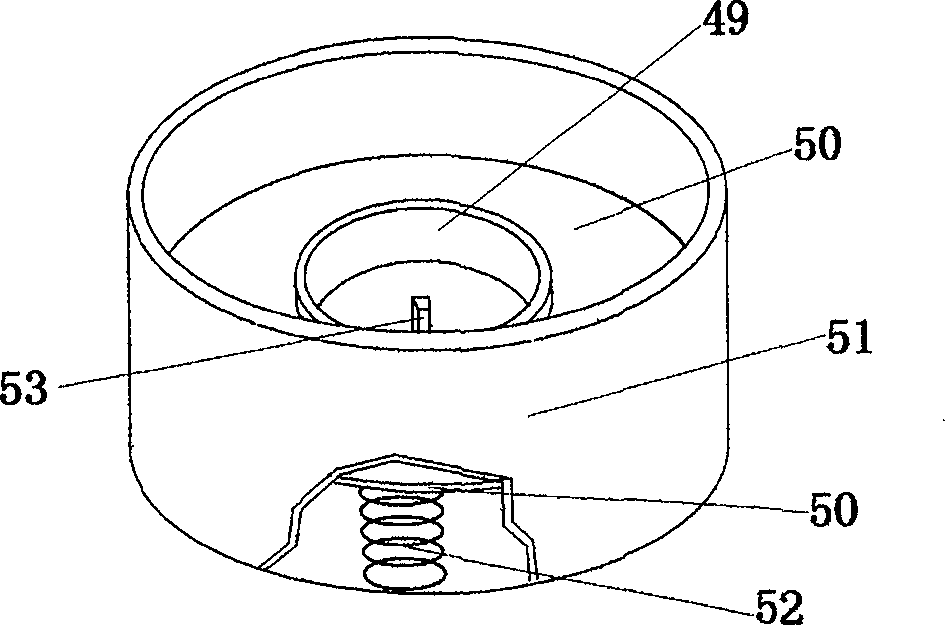

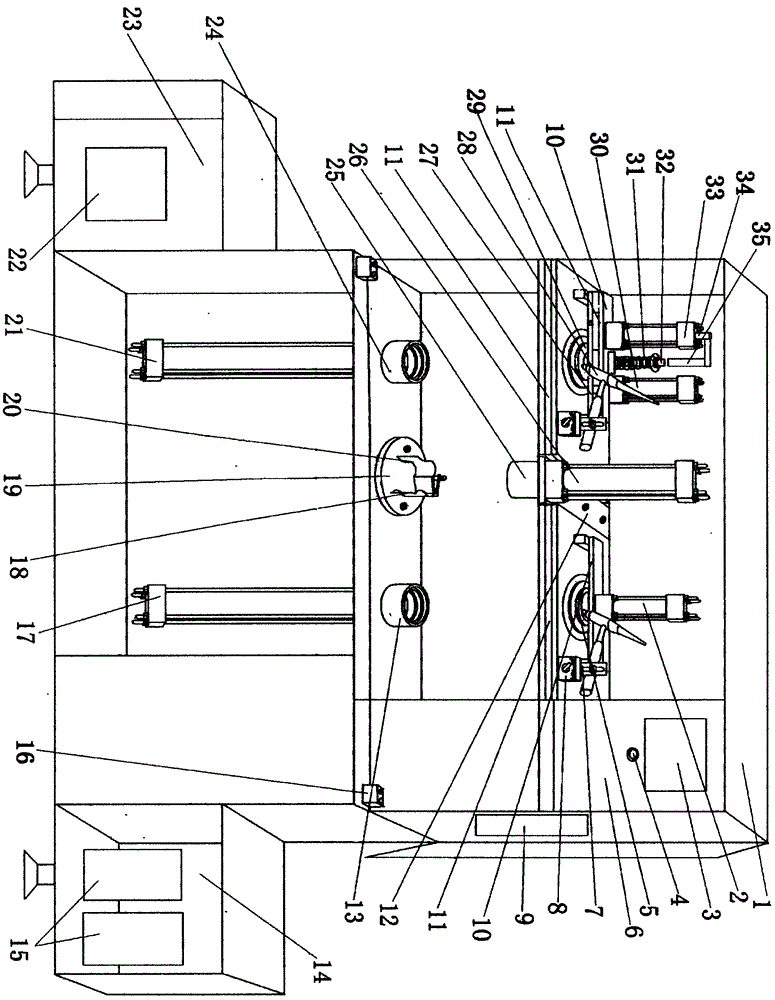

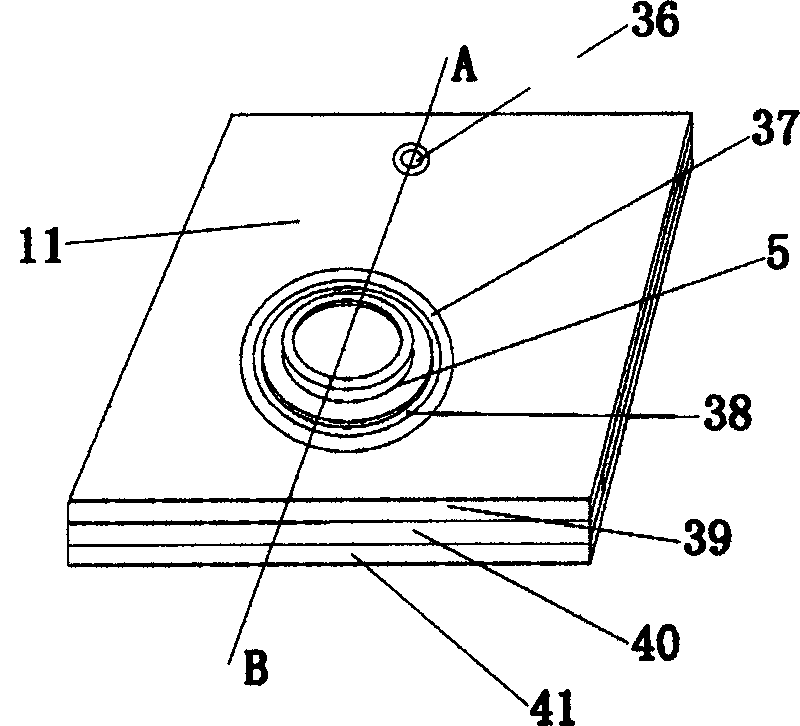

[0027] exist figure 1 Among them, the upper part of the frame is respectively equipped with a welding cup opening mechanism, a welding cup bottom mechanism and a pressing cup bottom mechanism. A small bearing and a large bearing are installed on the top, the small bearing is installed on the driving wheel, and the large bearing is installed on the driven wheel. In the cup cover 29, a fixed mount 10 is installed above the cup cover 29, the bottom of the fixed mount 10 is equipped with a movable plate 27, and the other end of the movable plate 27 is equipped with a small clip spring and an adjustable nut, and the fixed mount is pressed There are two round holes and rectangular holes, and the cup opening oil cylinder 30 and the cup opening oil cylinder 33 are respectively installed on the two round holes. The oil cylinder rod 34 is connected with the pressure rod 35, and the pressure rod 35 is placed on the push rod 32. The upper part of the push rod 32 is equipped with a large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com