Full-automatic keel door plate production assembly line

A technology for producing assembly lines and keel door panels, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of not improving output and production efficiency, reducing production efficiency, and wasting space, saving labor costs and equipment investment. , the effect of improving output and production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

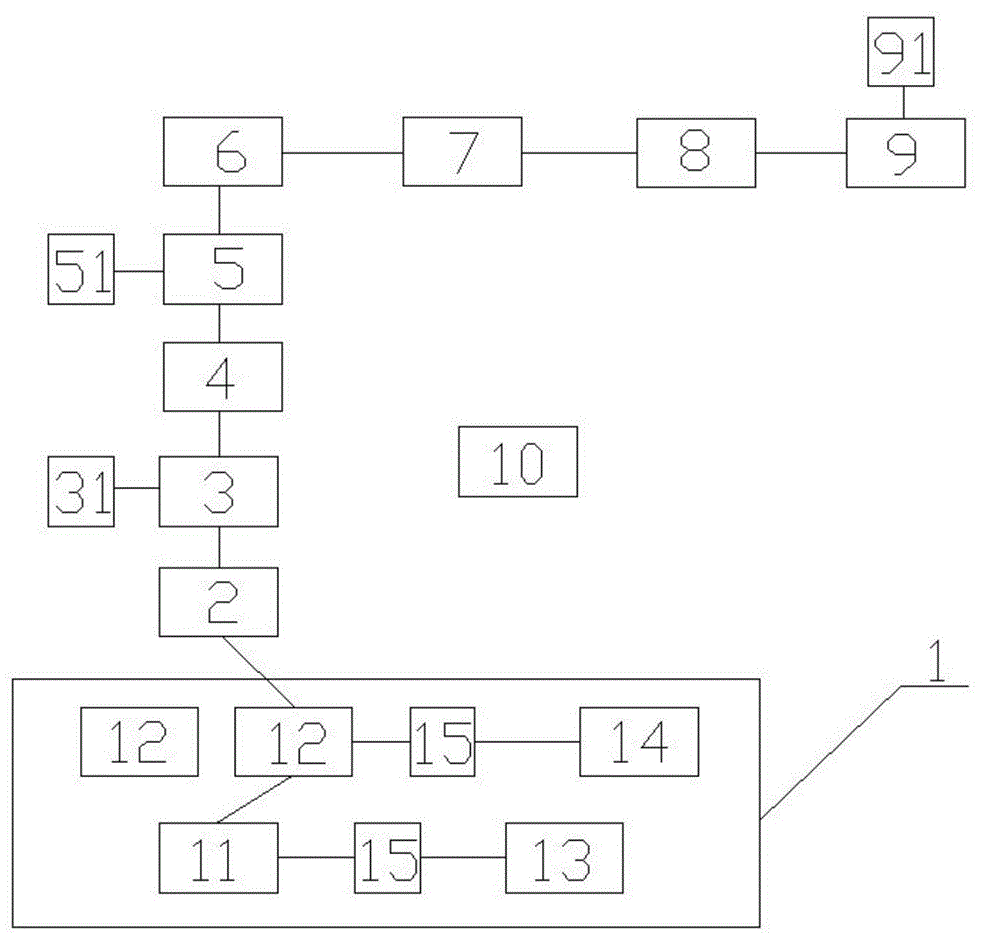

[0016] Such as figure 1 As shown, a fully automatic keel door panel production line, including forming machine 1, preheating unit 2, pouring unit 3, traction unit 4, heating device 5, cutting unit 6, semi-finished product sizing table 7, semi-finished buffer The area 8 and the packing unit 9 also include a rolling mill PLC computer control device 10 used to control the operation of the entire assembly line.

[0017] The forming machine includes a panel forming unit 11, two back panel forming units 12, a panel discharging unit 13 and a back panel discharging unit 14, the panel forming unit 11 is connected with the panel discharging unit 13, any back panel forming uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com