Narrow gauge bogie

A bogie and narrow-gauge technology, applied in the field of narrow-gauge bogies, can solve the problems such as the inability of the steering bearing structure to meet the requirements of narrow gauge, the large carrying capacity of railway vehicles and the fast running speed, etc., to improve braking and mitigation performance, The effect of simple structure and simplified manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

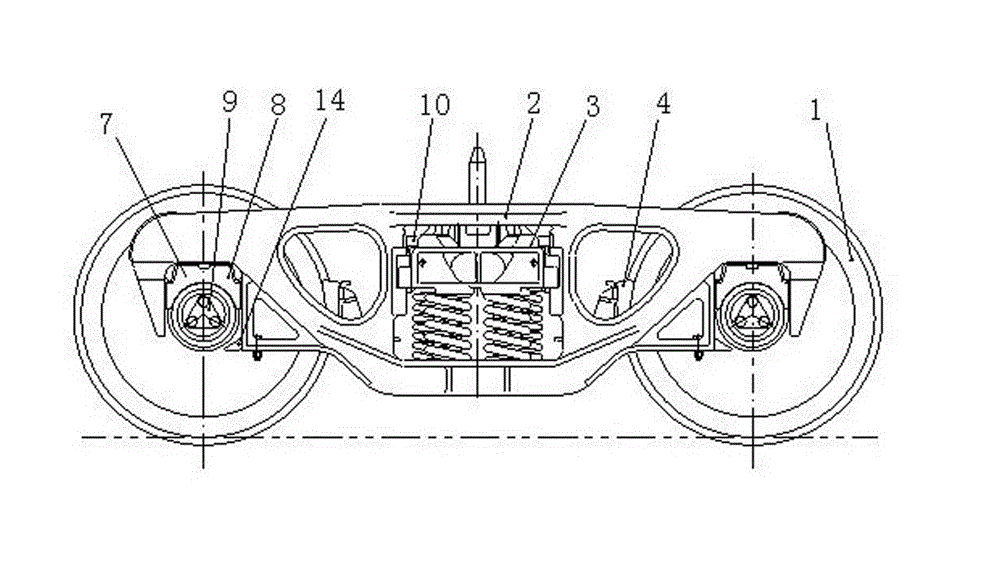

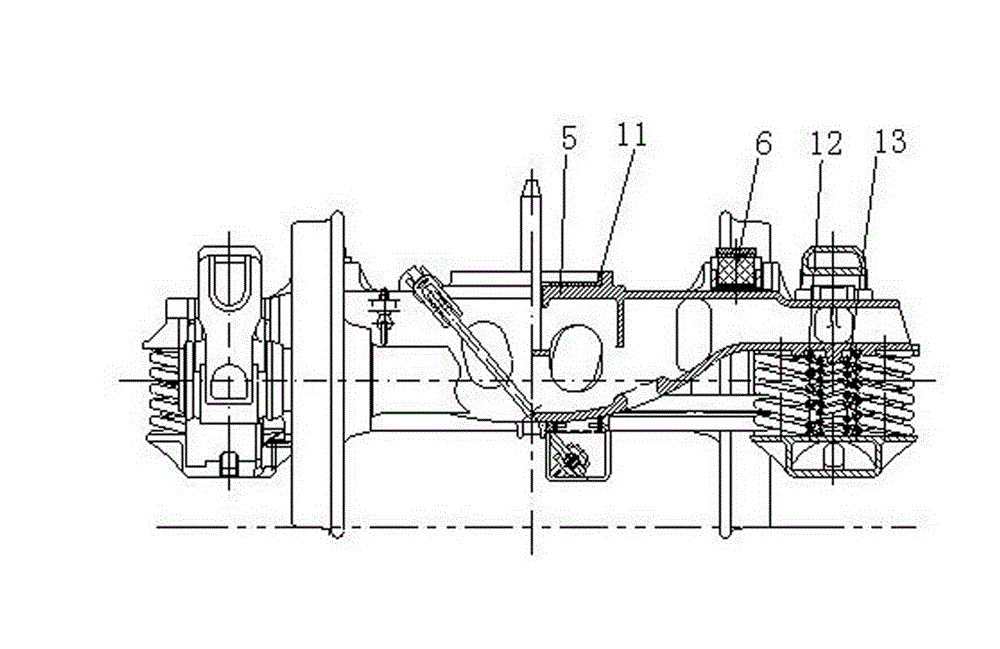

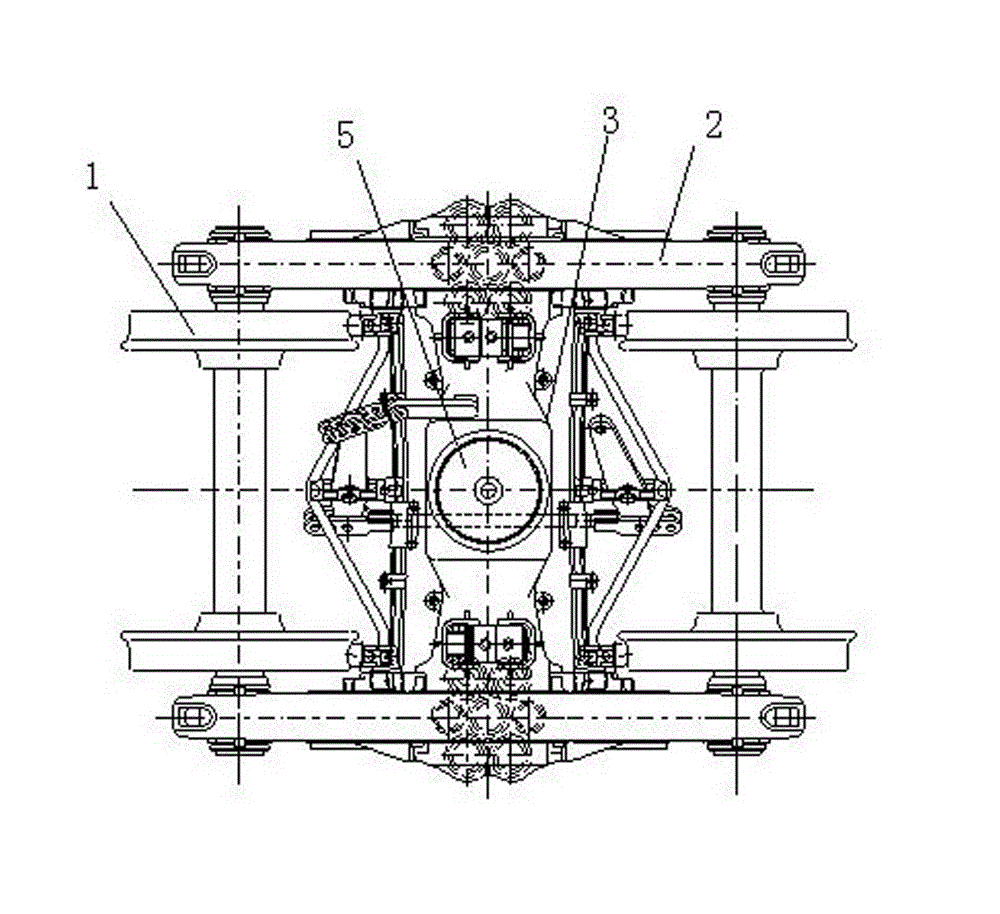

[0015] Narrow gauge bogies, such as figure 1 , 2 , 3, including front and rear wheel sets 1, two side frames 2, bolsters 3, outer circular springs 12, inner circular springs 13, braking devices 4, lower center discs 5, side bearings 6, guides at both ends of the side frames The frame 7 is installed on the front and rear wheel sets through the bearing saddle 8 and the rolling bearing device 9, and the two ends of the bolster are installed in the spring platform of the side frame through the spring damping device 10. Set the wear plate, the wear plate of the side frame column is fastened to the side frame column through the folded head bolt, the snap-in chute wear plate is installed in the side frame chute, the bolster and the lower center plate are integrated casting structure, and the lower center plate is press-fitted Center disc wear plate 11; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com