Carbon disulfide reacting furnace

A carbon disulfide and reaction furnace technology, applied in the field of carbon disulfide production, can solve the problems of limited production efficiency, small reaction chamber, high energy consumption, etc., and achieve the effects of improving production efficiency, increasing production capacity, and increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

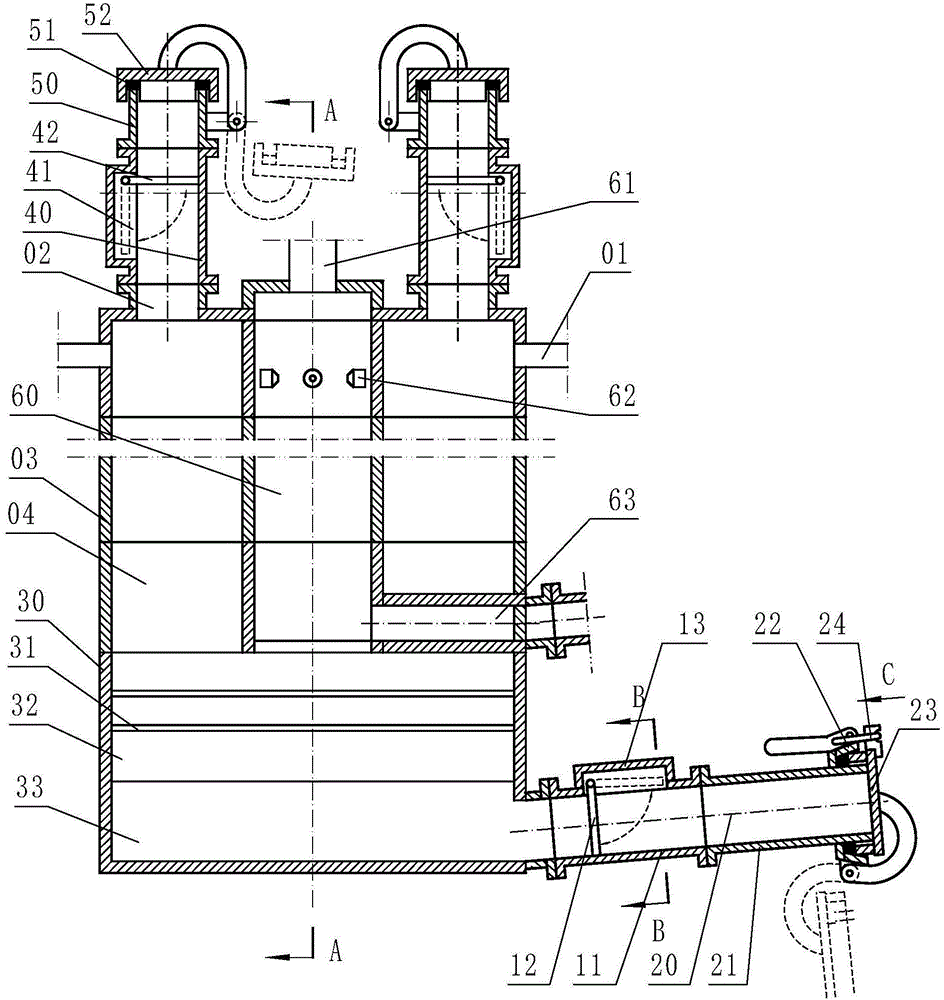

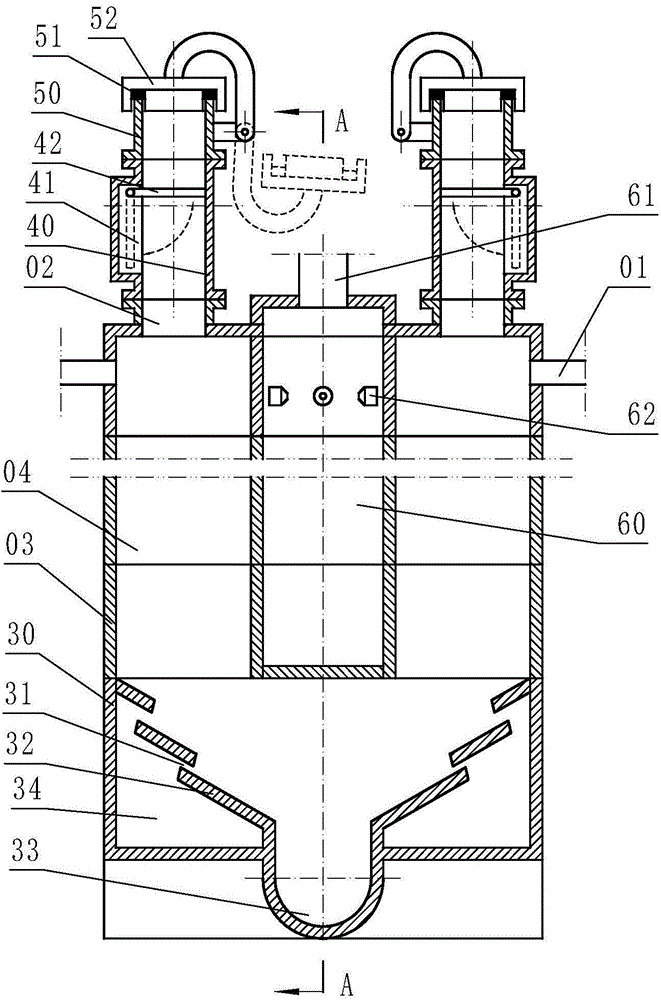

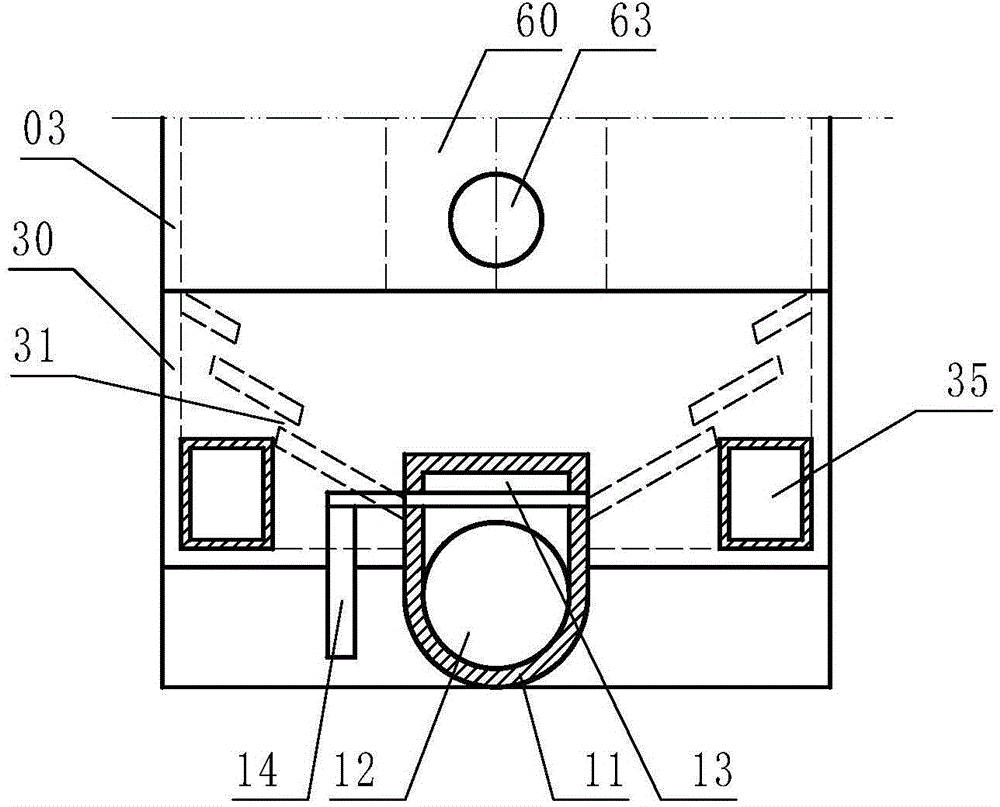

[0029] Example 1: Reference Figure 1 ~ Figure 4 , Is a schematic diagram of the structure of embodiment 1 of the present invention, including a furnace body 03, a reaction chamber 04, a furnace bottom 30, a discharge port 01 and a slag discharge port 20. The furnace body 03 is circular and is composed of a plurality of nodal members combined into a cylinder The furnace body 03 and the furnace bottom 30 are combined to form the reaction chamber 04. The central part of the reaction chamber 04 is provided with a vertical central heating chamber 60. The central heating chamber 60 includes an air inlet 61 and a smoke outlet 63. In this embodiment, the air inlet 61 is provided in the upper part of the reaction chamber 04, the smoke outlet 63 is provided in the lower part of the reaction chamber 04, and a heater 62 is provided in the central heating chamber 60. The heater 62 in this embodiment is a gas heater .

[0030] Four feeding ports 02 are provided on the upper part of the react...

Embodiment 2

[0038] Example 2: Reference Figure 5 , Is a schematic diagram of the structure of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that: the slag tank 33 and the slag tap 20 are both inclined upward and the bottom is in a straight line. The partition 32 between the 33 and the sulfur gasification chamber 34 is made of strip-shaped plates stacked up and down to form a louver shape, and there are vertical connecting reinforcing ribs in the middle.

Embodiment 3

[0039] Example 3: Reference Image 6 , Figure 7 , Is a schematic structural diagram of Embodiment 3 of the present invention. Compared with Embodiment 1 or 2, the difference of this embodiment is that the pores 31 of the partition plate 32 between the slag tank 33 and the sulfur gasification chamber 34 are circular Hole, the hole in the partition 32 from the sulfur gasification chamber 34 to the slag tank 33 is inclined from top to bottom, and the upper edge of the slag tank 33 side of the air hole 31 can completely cover the sulfur gasification chamber 34 The bottom edge of one side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com