A kind of photonic crystal film, its preparation method and application

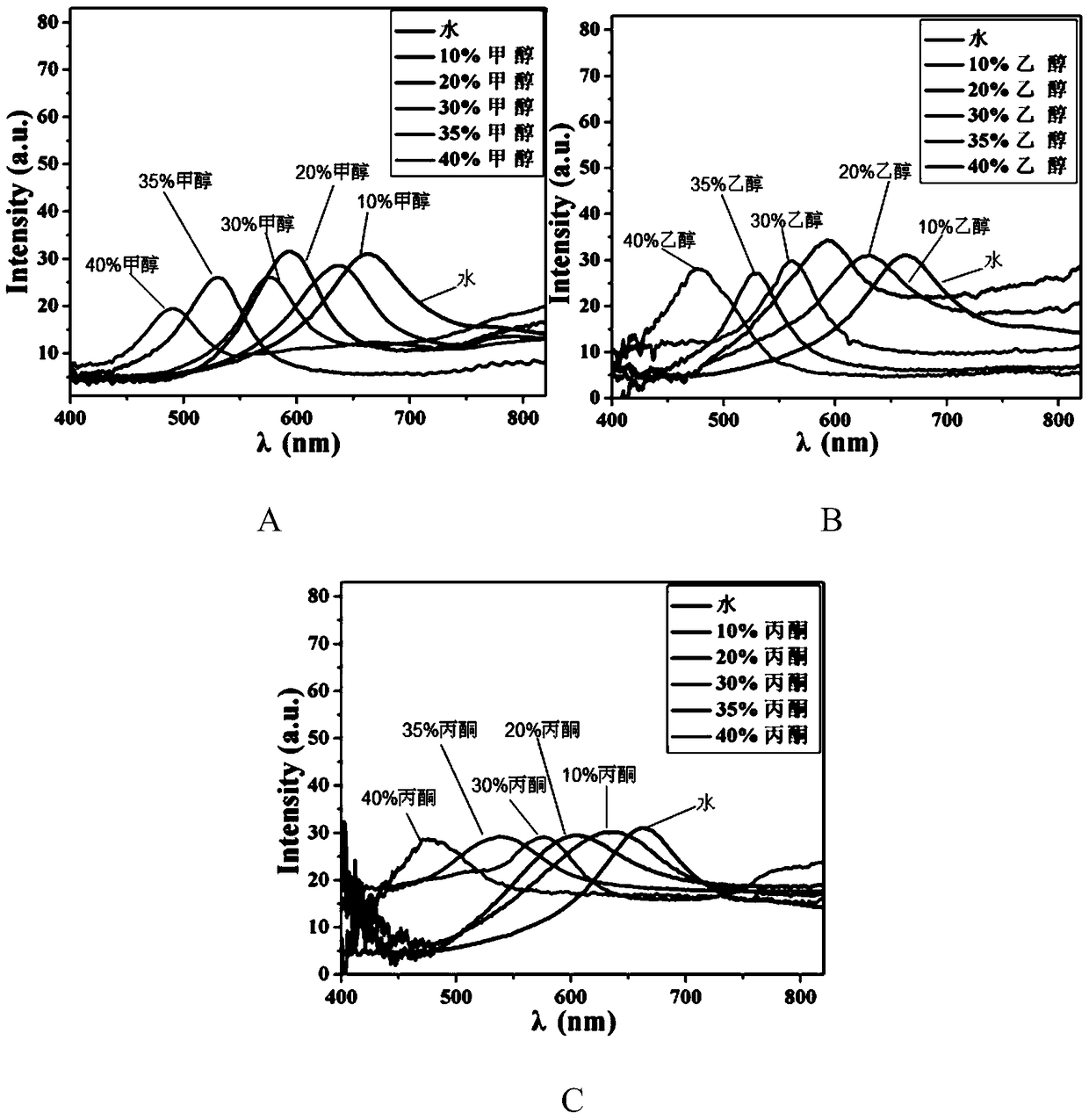

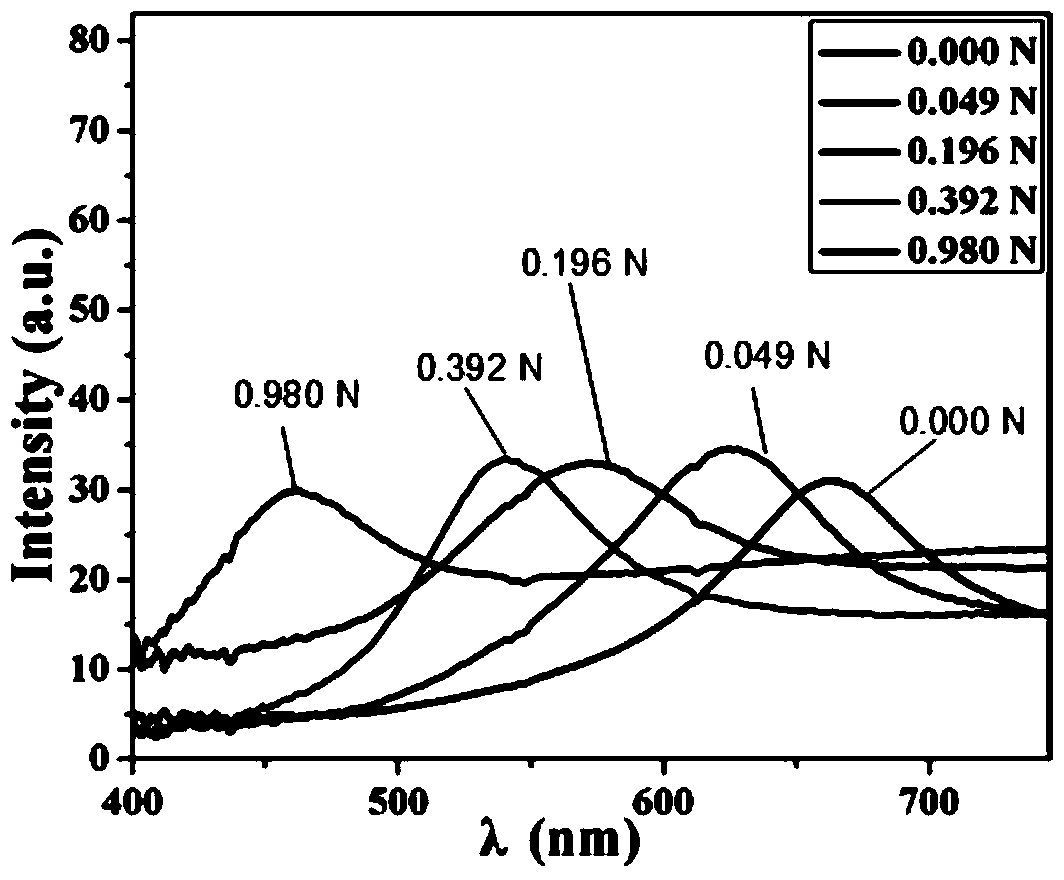

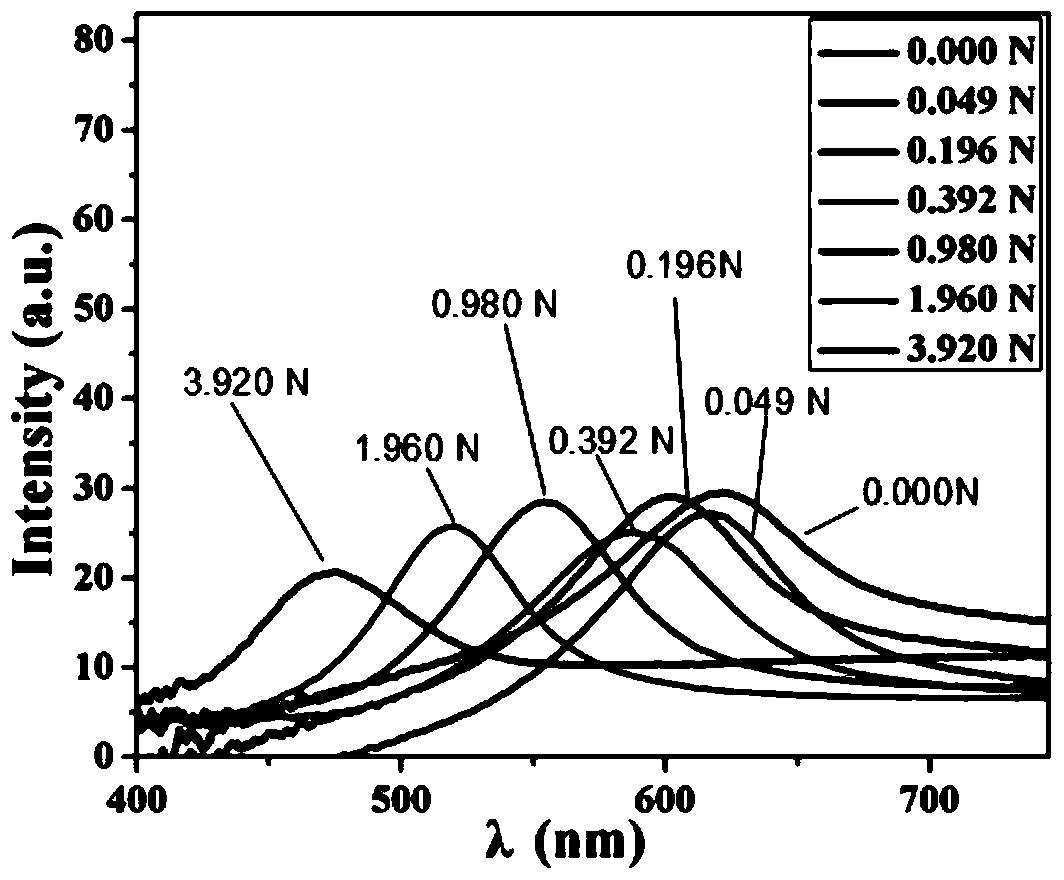

A technology of photonic crystals and thin films, which is applied in the measurement of color/spectral characteristics, the measurement of the change force of optical properties of materials when they are stressed, and the oxide of ferrous iron, can solve the problem of poor mechanical sensitivity and cannot be applied Naked eye detection, long preparation cycle of hydrogel photonic crystals and other issues, to achieve the effect suitable for large-scale production, short preparation time and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The photonic crystal thin film provided by the invention, its preparation method, comprises the following steps:

[0030] (1) Preparation of hydrogel photonic crystal precursor: Fe 3 o 4 Nanoparticles, acrylamide, methylene acrylamide and photoinitiator are uniformly dispersed in the organic solution to obtain a suspension of the hydrogel photonic crystal precursor, so that Fe in each milliliter of photonic crystal hydrogel precursor 3 o 4 1 mg to 50 mg of nanoparticles, 100 mg to 600 mg of acrylamide, 1 mg to 20 mg of methylene acrylamide, and 0.1 mg to 1 mg of photoinitiator; the organic solvent is ethylene glycol, and its function is to prevent Fe 3 o 4 The nanoparticles are separated under a magnetic field.

[0031] The Fe 3 o 4 Nanoparticles are prepared according to the following method: dissolving ferrocene and hydrogen peroxide in acetone to obtain a solution, so that the concentration of ferrocene in the solution is between 0.001 mg / ml and 0.05 mg / ml, and...

Embodiment 1

[0038] A photonic crystal thin film is prepared according to the following method:

[0039] (1) Preparation of hydrogel photonic crystal precursor: Fe 3 o 4 Nanoparticles, acrylamide, methylene acrylamide and photoinitiator are uniformly dispersed in ethylene glycol by ultrasonic dispersion method to obtain a suspension of hydrogel photonic crystal precursor, so that each milliliter of photonic crystal hydrogel precursor Contains Fe 3 o 4 Nanoparticles 1mg, acrylamide 100mg, methylene acrylamide 1mg, photoinitiator 0.1mg; ethylene glycol as an organic solvent can prevent Fe 3 o 4 The nanoparticles are separated under a magnetic field.

[0040] The Fe 3 o 4 Nanoparticles are prepared as follows: dissolve ferrocene and hydrogen peroxide in 75ml of acetone, and add the solution to a 100mL stainless steel reaction kettle, so that the concentration of ferrocene in the solution is 0.001mg / ml, and the concentration of hydrogen peroxide is 0.01mg / ml; react at 100°C for 10 hou...

Embodiment 2

[0046] A photonic crystal thin film is prepared according to the following method:

[0047] (1) Preparation of hydrogel photonic crystal precursor: Fe 3 o 4 Nanoparticles, acrylamide, methylene acrylamide and photoinitiator are uniformly dispersed in ethylene glycol by ultrasonic dispersion method to obtain a suspension of hydrogel photonic crystal precursor, so that each milliliter of photonic crystal hydrogel precursor Contains Fe 3 o 4 Nanoparticles 2mg, acrylamide 300mg, methylene acrylamide 4.5mg, photoinitiator 0.22mg; ethylene glycol as an organic solvent can prevent Fe 3 o 4 The nanoparticles are separated under a magnetic field.

[0048] The Fe 3 o 4 Nanoparticles are prepared as follows: dissolve ferrocene and hydrogen peroxide in 75ml of acetone, and add the solution to a 100mL stainless steel reaction kettle, so that the concentration of ferrocene in the solution is 0.0023mg / ml, and the concentration of hydrogen peroxide is 0.025mg / ml; react at 200°C for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com