Preparation method of paste material of PVC paste resin

A compounding method and paste resin technology, applied in the direction of adhesive additives, non-polymer adhesive additives, etc., can solve the problems of unfavorable paste storage and use, large changes in viscosity over time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] 1) Raw materials: PSH-10PVC paste resin produced by Shenyang Chemical Co., Ltd., dioctyl phthalate DOP or dibutyl phthalate DBP, dibutyltin dilaurate.

[0040] 2) Ratio range of parts by weight: PVC paste resin: plasticizer: its stabilizer=100:65:2.2.

[0041] 3) Equipment and instruments: precision electric mixer, vacuum mixer, vacuum grinder, NDJ-5S rotational viscometer, electronic scale, constant temperature water bath.

[0042] 4) Steps:

[0043] ①Use an electronic scale, respectively at 1 # Mixer (comparison 1), 2 # Weigh the same materials in the mixer (comparison 2) and the mortar (the present invention) according to the proportion; manually premix the materials in the mixer and the mortar for 3-10 minutes, and complete the first step of plasticizing.

[0044] ②Use a precision electric mixer, adjust the rotation speed to 1000rpm, set the time to 10min, for 1 # The materials in the mixer are dispersed, and the second step of plasticization is completed to obt...

example 2

[0057] Raw materials: PSH-30PVC paste resin produced by Shenyang Chemical Co., Ltd., butyl benzyl phthalate BBP, liquid calcium-zinc.

[0058] Ratio range of parts by weight: PVC paste resin: plasticizer: stabilizer=100:75:1.8

[0059] Production method, steps and equipment and instrument are identical with embodiment 1;

[0060] Data and processing see Table 4 , table 5 .

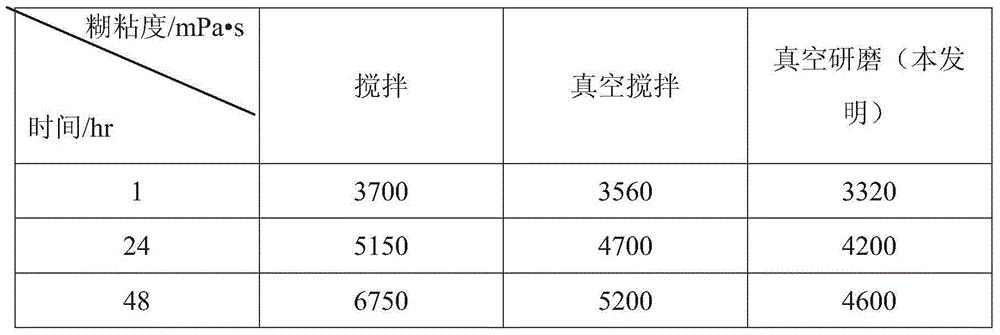

[0061] Table 4 .Comparison of viscosity changes over time of Shenyang Chemical PSH-30PVC paste resin paste

[0062]

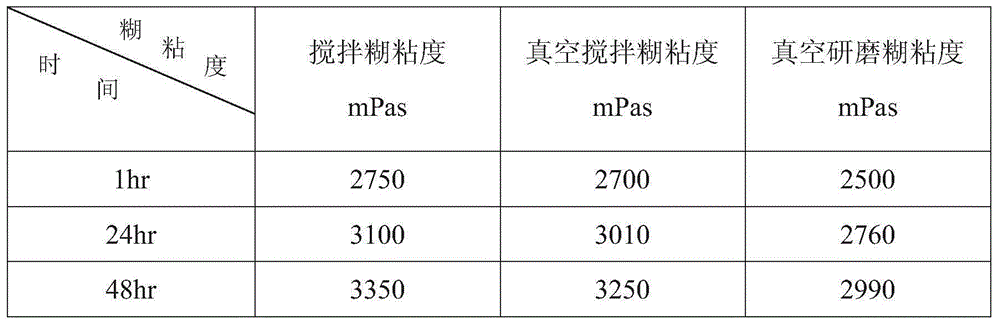

[0063] table 5 .Shenyang Chemical PSH-30PVC Paste Resin Viscosity Change Rate Over Time

[0064]

[0065] Depend on table 5 It can be seen from the data that the viscosity change rate of the PSH-30 paste after vacuum grinding is low over time.

example 3

[0067] Raw materials: PSM-31PVC paste resin produced by Shenyang Chemical Co., Ltd., diisononyl phthalate D1NP, liquid potassium-zinc;

[0068] Ratio range of parts by weight: PVC paste resin: plasticizer: stabilizer=100:60:2.5

[0069] Production method, steps and equipment and instrument are identical with embodiment 1;

[0070] Data and processing see Table 6 , Table 7 .

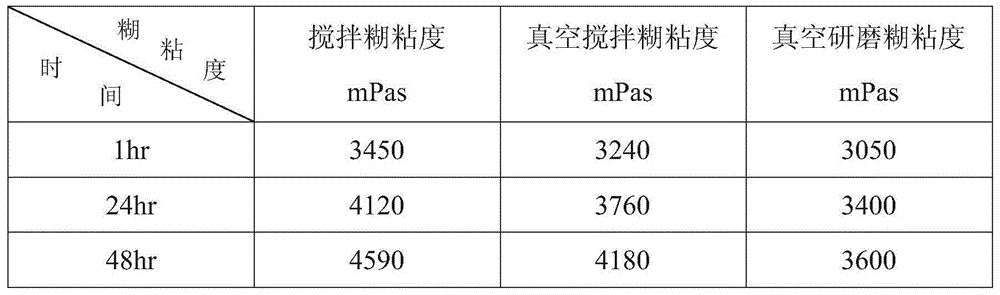

[0071] Table 6 .Comparison of viscosity changes over time of Shenyang Chemical PSM-31PVC paste resin paste

[0072]

[0073] Table 7 .Shenyang Chemical Industry PSM-31 polyvinyl chloride PVC paste resin viscosity change rate over time

[0074]

[0075] Depend on Table 7 It can be seen from the data that the viscosity change rate of the PSM-31 paste after vacuum grinding is low over time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com