Biotransformation method for preparing cocoa butter equivalent by adopting mutton fat as raw material

A technology for biotransformation and cocoa butter, applied in the field of microorganisms, to achieve the effects of cost reduction, continuous large-scale production, and rapid cell proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

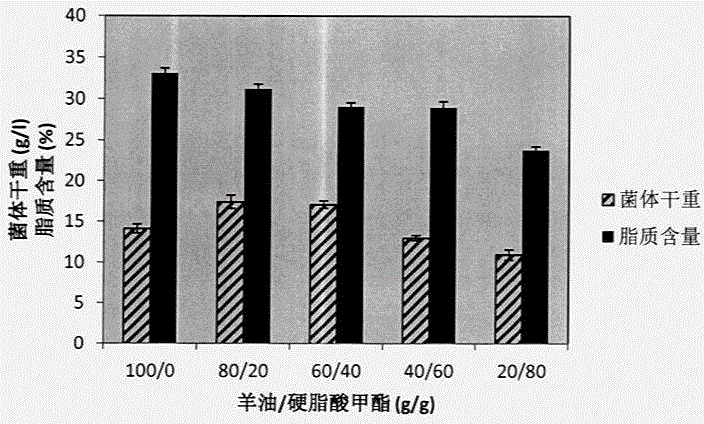

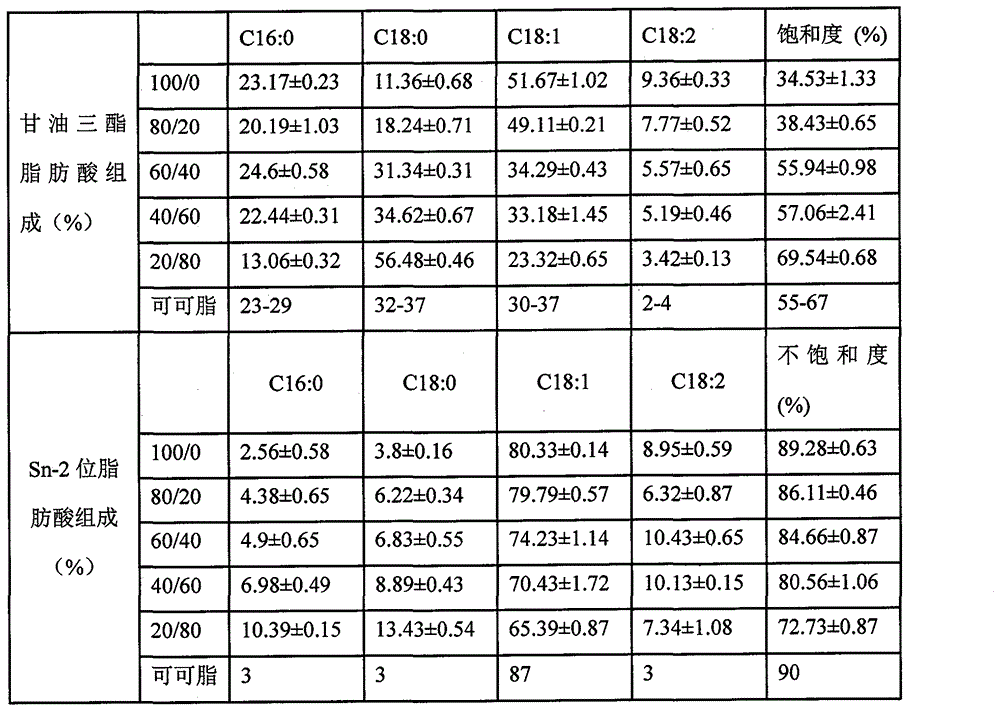

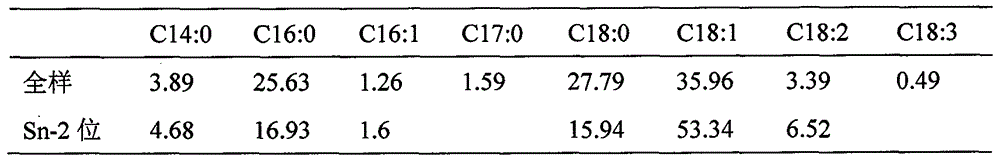

Examples

Embodiment 1

[0044] 1) Seed culture: inoculate according to the volume ratio of yeast liquid to seed medium 1:5000, temperature: 28°C; rotating speed of shaker: 200rpm; cultivation time: 24h, to obtain seed culture liquid; among them, the OD value of yeast liquid is 2.0.

[0045] 2) Fermentation culture: under sterile conditions, the above seed culture solution was inserted into the fermentation medium at a ratio of 10%, pH: 6; temperature: 30°C; shaking table speed: 200rpm; culture time: 72h, to obtain Fermentation broth.

[0046] 3) Cell collection and washing: filter the fermentation broth obtained in 2), and wash the cells twice with 95% ethanol and n-hexane to remove suet attached to the surface of the cells.

[0047] 4) Cell drying and lipid extraction: the cell was vacuum freeze-dried to constant weight, then the dry weight was measured, and the lipid was extracted with chloroform-methanol at a volume ratio of 2:1.

[0048] The composition of the fermentation medium used is as fol...

Embodiment 2

[0056] 1) Seed culture: inoculate according to the volume ratio of yeast liquid to seed medium 1:5000, temperature: 28°C; rotating speed of shaker: 200rpm; cultivation time: 24h, to obtain seed culture liquid; among them, the OD value of yeast liquid is 2.0.

[0057] 2) Fermentation culture: under sterile conditions, the above seed culture solution was inserted into the fermentation medium at a ratio of 10%, pH: 6; temperature: 30°C; shaking table speed: 200rpm; culture time: 72h, to obtain Fermentation broth.

[0058] 3) Cell collection and washing: filter the fermentation broth obtained in 2), and wash the cells twice with 95% ethanol and n-hexane to remove suet attached to the surface of the cells.

[0059] 4) Cell drying and lipid extraction: the cell was vacuum freeze-dried to constant weight, then the dry weight was measured, and the lipid was extracted with chloroform-methanol at a volume ratio of 2:1.

[0060] The composition of the fermentation medium used is as fol...

Embodiment 3

[0068] 1) Seed culture: inoculate according to the volume ratio of yeast liquid to seed medium 1:2000, temperature: 28°C; rotating speed of shaker: 200rpm; cultivation time: 24h, to obtain seed culture liquid; among them, the OD value of yeast liquid is 2.0.

[0069] 2) Fermentation culture: under sterile conditions, the above-mentioned seed culture solution is inserted into the fermentation medium at a ratio of 10%, pH: 5-7; temperature: 25-30°C; shaker speed: 150-250rpm; Cultivation time: 72-96h to obtain a fermentation culture solution.

[0070] 3) Cell collection and washing: filter the fermentation broth obtained in 2), and wash the cells twice with 95% ethanol and n-hexane to remove suet attached to the surface of the cells.

[0071] 4) Cell drying and lipid extraction: the cell was vacuum freeze-dried to constant weight, then the dry weight was measured, and the lipid was extracted with chloroform-methanol at a volume ratio of 2:1.

[0072] The composition of the ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com